Functional Safety Design and ISO26262 Compliance for BMS

May 25, 2023 · To ensure the safety of battery pack and the vehicle, companies need to follow safety norms by following ISO26262 functional safety standard for road vehicles. The

AN215 Functional Safety for BMS Solution: According to

Oct 10, 2023 · INTRODUCTION This application note discusses the recommended safety measures to be implemented in the BMS architecture based on an MPS battery monitor and

AN215 Functional Safety for BMS Solution: According to

Oct 21, 2021 · The increasing use of lithium batteries and the necessary integration of battery management systems (BMS) has led international standards to demand functional safety in

Functional safety-relevant wireless communication in

Sep 6, 2023 · To speed automakers'' development time for wireless BMS, we requested that TÜV SÜD, the industry''s leading functional safety authority, independently evaluate the quantitative

How is functional safety defined & implemented

Jul 17, 2023 · This FAQ reviews the importance of maintaining operation in the safe operating area (SOA) of lithium batteries along with the functions of the

tery r and battery''s Functional S

Mar 7, 2025 · Introduction Battery-powered applications, which have become indispensable over the last decade, require a certain level of protection to ensure safe use. This safety is provided

Functional Safety Assessment of Battery Management

Aug 27, 2023 · There has been an exponential increase in the usage of electric vehicles in recent years. Electric vehicles are powered by batteries for all their functions. Battery management

The Role of Functional Safety in Electric Vehicles (EVs): How

Oct 5, 2024 · ISO 26262, the international standard for functional safety, is crucial for ensuring the safe development of these systems throughout their lifecycle. This standard applies not only to

Energy Storage System (ESS) – Functional Safety

5 days ago · 2. Battery Management Systems (BMS): The BMS is at the heart of any energy storage system''s safety. It constantly monitors the state of health of each battery cell, tracks

Battery BMS Advantages: From Functional Safety to Cost

Aug 18, 2025 · Battery BMS Advantages: From Functional Safety to Cost Reduction An efficient battery BMS (Battery Management System) is more important than ever as the need for high

Beyond the Battery: Functional Safety in Electric Vehicles

Dec 5, 2023 · Discover the crucial role of functional safety in EVs, extending beyond battery safety. Learn about ISO 26262, hazard analysis, cybersecurity with UL Solutions.

Functional Safety in Non-Automotive BMS Designs

Learn about the role that functional safety plays in non-automotive battery management systems and how to achieve the required safety level for your application using the MP279x family.

High-Voltage ESS Reference Development Platform

May 31, 2024 · BMS is the first line of defense to monitor, balance and optimize the battery health & performance in real-time, allowing improved power system eficiency, lifetime and safety of

Critical review and functional safety of a battery

May 21, 2022 · The paper firstly provides a brief introduction to the key composition of the BMS, specifically for high energy battery pack systems, and then illustrates the typical BMS topology

BFE Family Functional Safety Manual

Nov 28, 2024 · Functional Safety in Battery Management Systems Featuring Renesas Battery Front Ends This manual covers several recommended usage and mechanisms of Renesas

Functional Safety Considerations in Battery Management

Jul 29, 2022 · There are functional safety considerations for the electrical system that maintains the battery in a safe operating range while the vehicle is in use or charging. Li-ion batteries (as

Mastering ISO 26262 for BMS

Jun 13, 2025 · One crucial standard that BMS developers must adhere to is ISO 26262, a functional safety standard designed for the automotive industry. In this article, we will explore

BFE Family Functional Safety Manual

Sep 19, 2022 · Manual Functional Safety in Battery Management Systems Featuring Renesas Battery Front Ends This manual covers several recommended usage and mechanisms of

Cell balancing, battery state estimation, and safety aspects of battery

Jan 1, 2015 · Further, battery state estimation with cell models, safety aspects of BMS regarding functional safety based on ISO 26262, standard safety measures and devices of automotive

Learn More

- Bms main control battery

- Libreville BMS Battery Management System

- Features of Kuala Lumpur BMS battery management power system

- Maseru BMS Battery Management Power System Architecture

- Bms lithium battery customization

- San Marino BMS battery management control system manufacturer

- Tripoli RV battery bms wholesale

- BMS component installation structure of battery module

- Can t the battery with BMS be fully charged

Industrial & Commercial Energy Storage Market Growth

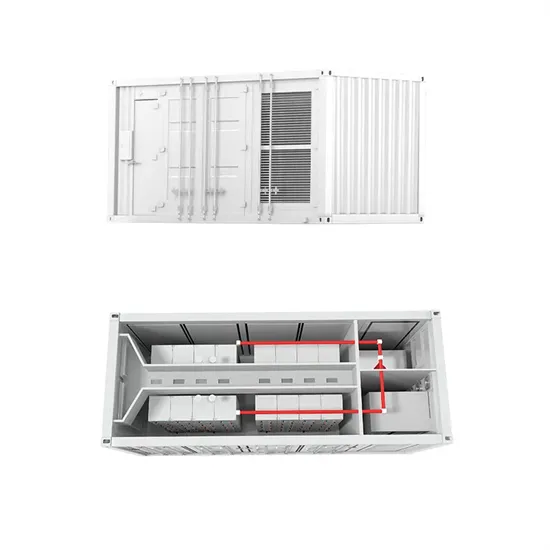

The global industrial and commercial energy storage market is experiencing explosive growth, with demand increasing by over 250% in the past two years. Containerized energy storage solutions now account for approximately 45% of all new commercial and industrial storage deployments worldwide. North America leads with 42% market share, driven by corporate sustainability initiatives and tax incentives that reduce total project costs by 18-28%. Europe follows closely with 35% market share, where standardized industrial storage designs have cut installation timelines by 65% compared to traditional built-in-place systems. Asia-Pacific represents the fastest-growing region at 50% CAGR, with manufacturing scale reducing system prices by 20% annually. Emerging markets in Africa and Latin America are adopting industrial storage solutions for peak shaving and backup power, with typical payback periods of 2-4 years. Major commercial projects now deploy clusters of 15+ systems creating storage networks with 80+MWh capacity at costs below $270/kWh for large-scale industrial applications.

Industrial Energy System Innovations & Cost Benefits

Technological advancements are dramatically improving industrial energy storage performance while reducing costs. Next-generation battery management systems maintain optimal operating conditions with 45% less energy consumption, extending battery lifespan to 20+ years. Standardized plug-and-play designs have reduced installation costs from $85/kWh to $40/kWh since 2023. Smart integration features now allow multiple industrial systems to operate as coordinated energy networks, increasing cost savings by 30% through peak shaving and demand charge management. Safety innovations including multi-stage fire suppression and thermal runaway prevention systems have reduced insurance premiums by 35% for industrial storage projects. New modular designs enable capacity expansion through simple system additions at just $200/kWh for incremental capacity. These innovations have improved ROI significantly, with commercial and industrial projects typically achieving payback in 3-5 years depending on local electricity rates and incentive programs. Recent pricing trends show standard industrial systems (1-2MWh) starting at $330,000 and large-scale systems (3-6MWh) from $600,000, with volume discounts available for enterprise orders.