Industrial Battery Management System (BMS) devices

Oct 13, 2023 · STSW-L9961BMS Firmware package, containing source code and binaries, with standalone firmware driver and application examples (*) * battery voltage, current and

Understanding BMS Connection Diagram: From MOSFET Control

Aug 19, 2025 · Understanding BMS Connection Diagram: From MOSFET Control to Cell Balancing To ensure safety, dependability, and efficiency in contemporary lithium-ion and

Battery management system and battery disconnect unit

The battery management system and electronical battery disconnect unit consist of several components designed to monitor, manage, control, and disconnect the battery cells of a

Design points and process requirements for the BMS main control

The bms main control board is very important in battery management systems for evs. It keeps the battery safe and helps it work well all the time. Engineers use hardware and software

What is Battery Management System (BMS)?

Dec 3, 2024 · A battery management system, or BMS for short, is an electrical system that regulates and maintains a battery''s performance. By regulating several factors, including

Battery Management System (BMS) Detailed Explanation:

May 7, 2025 · BMS is like a 24-hour on duty ''battery doctor'', mainly responsible for completing six major tasks: Collect voltage, current, temperature and other data to ensure transparency of

Battery Management System (BMS) Detailed Explanation:

May 7, 2025 · Battery Management System (BMS) is the "intelligent manager" of modern battery packs, widely used in fields such as electric vehicles, energy storage stations, and consumer

Battery Management System (BMS): Diagrams & IC Selection

Aug 19, 2025 · Battery Management System (BMS) explained: key functions, block/circuit diagrams (PDF), LiFePO4 notes, 12V/24V/3S cases, and cross-brand IC choices with price

What Is a BMS in Batteries? Definition, Functions,

Jun 10, 2025 · A Battery Management System (BMS) is the intelligent controller that ensures batteries are used safely, efficiently, and reliably. Whether you''re

Understanding the Circuit Diagram of a Battery Management

A battery management system (BMS) is an integral part of battery-powered systems, ensuring the safe and efficient operation of the batteries. A BMS typically consists of several components

The Complete Guide to A Battery Management Systems

Aug 31, 2023 · Lithium-ion batteries, especially custom lithium ion battery packs, need a BMS (Battery Management System) to ensure the battery is reliable and safe. The battery

What is a Battery Management System (BMS)? –

1 day ago · Battery management system (BMS) is technology dedicated to the oversight of a battery pack, which is an assembly of battery cells, electrically

What is a Battery Management System? Complete Guide to BMS

Aug 3, 2025 · A Battery Management System (BMS) is an electronic control unit that monitors and manages rechargeable battery packs to ensure safe operation, optimal performance, and

6 FAQs about [Bms main control battery]

What is a battery management system (BMS)?

From electric vehicles to renewable energy storage systems, BMS technology has become essential for safely harnessing the power of advanced battery chemistries. Understanding how these systems work can help you make informed decisions about battery-powered devices and applications. What Are Battery Management Systems?

Do lithium ion batteries need a BMS system?

Lithium-ion batteries, especially custom lithium ion battery packs, need a BMS (Battery Management System) to ensure the battery is reliable and safe. The battery management system is the brain of the lithium battery and reports the status and health of the battery. Let’s get a better understanding from this article. What is a BMS System?

What is a BMS control unit?

The control unit processes data collected from the battery and ensures that the system operates within its safe operating area. A critical part of the BMS, this system uses air cooling or liquid cooling to maintain the temperature of the battery cells.

What is a battery management system?

A battery management system represents one of the most critical safety and performance components in modern energy storage applications. At its core, a BMS serves as an intelligent guardian that continuously monitors individual battery cells and the overall pack to prevent potentially dangerous situations while maximizing efficiency and longevity.

Do you need a battery management system?

They do, however, have a reputation of occasionally bursting and burning all that energy should they experience excessive stress. This is why they often require battery management systems (BMSs) to keep them under control. In this article, we'll discuss the basics of the BMS concept and go over a few foundational parts that make up the typical BMS.

What is a battery balancing system (BMS)?

By identifying and mitigating unsafe operating conditions, the BMS ensures the safe operation of the battery pack and the connected device. It prevents overcharging, over discharging, and thermal runaway. To maintain uniformity across individual cells, the BMS incorporates a cell balancing function.

Learn More

- Flow battery BMS control cabinet

- Battery energy storage system main equipment main control board for communication base station

- Differences between master and slave control of battery system BMS

- Precision Control Lithium Battery BMS

- European BMS battery management control system manufacturer

- Characteristics of Iran s BMS battery management control system

- Iraq battery management system bms

- Intelligent Battery Management System BMS

- BMS battery management system voltage

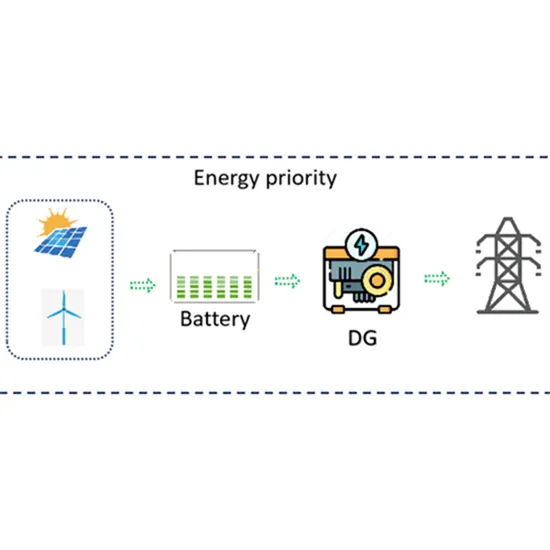

Industrial & Commercial Energy Storage Market Growth

The global industrial and commercial energy storage market is experiencing explosive growth, with demand increasing by over 250% in the past two years. Containerized energy storage solutions now account for approximately 45% of all new commercial and industrial storage deployments worldwide. North America leads with 42% market share, driven by corporate sustainability initiatives and tax incentives that reduce total project costs by 18-28%. Europe follows closely with 35% market share, where standardized industrial storage designs have cut installation timelines by 65% compared to traditional built-in-place systems. Asia-Pacific represents the fastest-growing region at 50% CAGR, with manufacturing scale reducing system prices by 20% annually. Emerging markets in Africa and Latin America are adopting industrial storage solutions for peak shaving and backup power, with typical payback periods of 2-4 years. Major commercial projects now deploy clusters of 15+ systems creating storage networks with 80+MWh capacity at costs below $270/kWh for large-scale industrial applications.

Industrial Energy System Innovations & Cost Benefits

Technological advancements are dramatically improving industrial energy storage performance while reducing costs. Next-generation battery management systems maintain optimal operating conditions with 45% less energy consumption, extending battery lifespan to 20+ years. Standardized plug-and-play designs have reduced installation costs from $85/kWh to $40/kWh since 2023. Smart integration features now allow multiple industrial systems to operate as coordinated energy networks, increasing cost savings by 30% through peak shaving and demand charge management. Safety innovations including multi-stage fire suppression and thermal runaway prevention systems have reduced insurance premiums by 35% for industrial storage projects. New modular designs enable capacity expansion through simple system additions at just $200/kWh for incremental capacity. These innovations have improved ROI significantly, with commercial and industrial projects typically achieving payback in 3-5 years depending on local electricity rates and incentive programs. Recent pricing trends show standard industrial systems (1-2MWh) starting at $330,000 and large-scale systems (3-6MWh) from $600,000, with volume discounts available for enterprise orders.