How to design an energy storage cabinet: integration and

Jan 3, 2025 · This article will introduce in detail how to design an energy storage cabinet device, and focus on how to integrate key components such as PCS (power conversion system), EMS

A critical review on operating parameter monitoring/estimation, battery

Nov 15, 2024 · A critical review on operating parameter monitoring/estimation, battery management and control system for redox flow batteries

Battery management system for industrial-scale vanadium redox flow

Jul 31, 2020 · Abstract This paper describes the battery management system (BMS) developed for a 9 kW/27 kWh industrial scale vanadium redox flow battery (VRFB), both in terms of

Battery management system for industrial-scale vanadium redox flow

Jul 31, 2020 · This paper describes the battery management system (BMS) developed for a 9 kW/27 kWh industrial scale vanadium redox flow battery (VRFB), both in terms of hardware

Industrial-Grade Lithium Ion Battery Storage Cabinets:

The integrated Battery Management System (BMS) represents the pinnacle of intelligent energy storage control. This sophisticated system continuously monitors and optimizes various

Battery and energy management system for vanadium redox flow battery

Feb 1, 2023 · As one of the most promising large-scale energy storage technologies, vanadium redox flow battery (VRFB) has been installed globally and integrated with microgrids (MGs),

Functional and Safety Guide for Battery Management System (BMS

Master Control System communication is detected within a controllable period of time and that the outputs of the degraded BMS place the Battery System in a safe state. Corruption of safety

电池管理系统BMS知识与功能,一篇入门

Aug 26, 2021 · 1)什么是BMS? BMS全称是Battery Management System, 电池管理系统。它是配合监控储能电池状态的设备,主要就是为了智能化管理及维

Customized Liquid Flow Battery "Housekeeper": How to

Jul 8, 2025 · Liquid flow batteries have become an ideal choice for long-duration energy storage due to their large capacity, long lifespan, and high safety. The reliability and stability of their

Battery and energy management system for Vanadium

Dec 11, 2022 · As one of the most promising large-scale energy storage technologies, vanadium redox flow battery (VRFB) has been installed glob-ally and integrated with microgrids (MGs),

Energy Storage Battery BMS Cabinet: The Brain Behind

Key Players in the Cabinet Battery Management System (BMS): The Sherlock Holmes of voltage detection – it sniffs out cell imbalances faster than you notice a dead smartphone battery [9].

Development and Demonstration of Redox Flow Battery

Jan 8, 2021 · High expectations have been placed on rechargeable batteries as a key technology to power system reliability associated with introduction of an increasing volume of renewable

ST BMS kit solution 电池管理系统整体解决方案

Jul 8, 2020 · Battery management system Automotive BMS must be able to meet critical features such as voltage, temperature and current monitoring, battery state of charge (SoC) and cell

How to Design a Battery Management

Aug 4, 2022 · The battery management system (BMS) monitors the battery and possible fault conditions, preventing the battery from situations in which it can degrade, fade in capacity, or

Understanding the Role of BMS, EMS, and PCS in Battery

Jan 10, 2025 · Discover the critical roles of BMS, EMS, and PCS in Battery Energy Storage Systems (BESS). Learn how these components ensure safety, efficiency, and reliability in

Battery Management Systems (BMS)

Aug 28, 2023 · Flow battery BMS: Used in large-scale energy storage applications that use flow batteries. They typically include monitoring the electrolyte levels, temperature, flow rates, and

BMS for Lithium-Ion Batteries: The Essential Guide to Battery

Jul 22, 2025 · Comprehensive guide to BMS for lithium-ion batteries. Learn battery management system functions, safety features, and protection mechanisms in 2025.

What is a BMS Board? The Key to Efficient Battery

Apr 3, 2025 · 1. Introduction to BMS Boards A Battery Management System (BMS) board is a critical component in modern energy storage systems, ensuring optimal performance, safety,

6 FAQs about [Flow battery BMS control cabinet]

What is a battery management system (BMS)?

The battery management system (BMS) monitors the battery and possible fault conditions, preventing the battery from situations in which it can degrade, fade in capacity, or even potentially harm the user or surrounding environment.

Do VRFBs need a battery management system?

As with any battery technology, VRFBs require a suitable battery management system (BMS) that takes into account the properties of the battery and operates it in the most cost-efective and reliable fashion .

Why are battery models used in a BMS?

Generally, battery models are used within a BMS to ensure safe operation, optimisation and data process-ing, which help improve the battery system’s performance un-der various physical constraints.

How a BMS protects a VRFB system?

The BMS protection could include operation mode detection, setting fault criteria, temperature management and overheating protection, fault de-tection, predicting system states, isolation fault detection, etc. . Also, some local decision-making intelligence is needed for the BMS to protect the VRFB system by isolating the bat-tery cells.

Why do we need a special BMS design for VRFB batteries?

Moreover, unlike conventional solid-state batteries, VRFBs sufer from electrolyte thermal precipitation, vanadium ion imbalance and hydrogen evolution which need to be considered for the overall system’s safety and reliability. Therefore, a special BMS design is needed to handle the dif-ferences and constraints associated with VRFBs.

What is vanadium redox flow battery (VRFB)?

As one of the most promising large-scale energy storage technologies, vanadium redox flow battery (VRFB) has been installed glob-ally and integrated with microgrids (MGs), renewable power plants and residential applications.

Learn More

- Inverter battery control cabinet

- Energy storage cabinet BMS control

- Address of the flow battery energy storage cabinet of the Eritrean communication base station

- San Marino BMS battery management control system manufacturer

- Slovenia communication base station flow battery cabinet

- Bangladesh BMS battery exchange cabinet

- Spanish BMS battery exchange cabinet

- Beiya BMS battery exchange cabinet

- Differences between master and slave control of battery system BMS

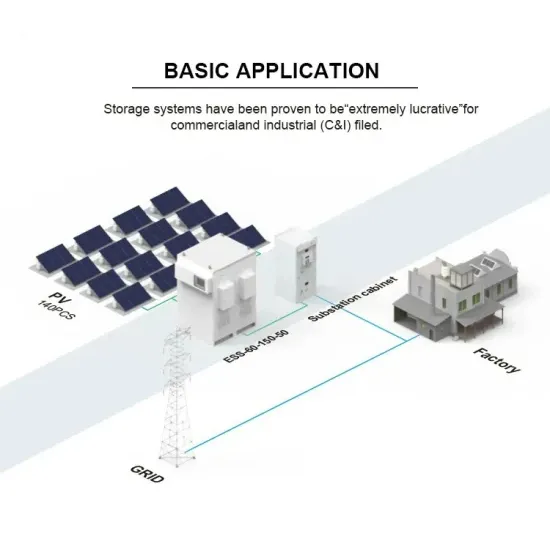

Industrial & Commercial Energy Storage Market Growth

The global industrial and commercial energy storage market is experiencing explosive growth, with demand increasing by over 250% in the past two years. Containerized energy storage solutions now account for approximately 45% of all new commercial and industrial storage deployments worldwide. North America leads with 42% market share, driven by corporate sustainability initiatives and tax incentives that reduce total project costs by 18-28%. Europe follows closely with 35% market share, where standardized industrial storage designs have cut installation timelines by 65% compared to traditional built-in-place systems. Asia-Pacific represents the fastest-growing region at 50% CAGR, with manufacturing scale reducing system prices by 20% annually. Emerging markets in Africa and Latin America are adopting industrial storage solutions for peak shaving and backup power, with typical payback periods of 2-4 years. Major commercial projects now deploy clusters of 15+ systems creating storage networks with 80+MWh capacity at costs below $270/kWh for large-scale industrial applications.

Industrial Energy System Innovations & Cost Benefits

Technological advancements are dramatically improving industrial energy storage performance while reducing costs. Next-generation battery management systems maintain optimal operating conditions with 45% less energy consumption, extending battery lifespan to 20+ years. Standardized plug-and-play designs have reduced installation costs from $85/kWh to $40/kWh since 2023. Smart integration features now allow multiple industrial systems to operate as coordinated energy networks, increasing cost savings by 30% through peak shaving and demand charge management. Safety innovations including multi-stage fire suppression and thermal runaway prevention systems have reduced insurance premiums by 35% for industrial storage projects. New modular designs enable capacity expansion through simple system additions at just $200/kWh for incremental capacity. These innovations have improved ROI significantly, with commercial and industrial projects typically achieving payback in 3-5 years depending on local electricity rates and incentive programs. Recent pricing trends show standard industrial systems (1-2MWh) starting at $330,000 and large-scale systems (3-6MWh) from $600,000, with volume discounts available for enterprise orders.