Microcontroller-Based Platform for Lithium-Ion

Apr 1, 2025 · Efficient and safe charging of lithium-ion batteries is essential for maximizing their lifespan and performance. This paper presents the design

AUTOMATIC BATTERY CHARGER FOR MOBILE

Nov 4, 2014 · ABSTRACT This project aims to upgrade the efficiency and reliability of traditional charging by introducing an automatic battery charger using solar photovoltaic (PV) module

Top Lithium Solar Charge Controllers 2023 | ZHCSolar Review

Feb 28, 2023 · The Lithium Solar Charge Controller is a type of charge controller specially optimised for charging Lithium-ion and LifePo4 batteries. For a long time, solar charge

Solar Panel Tracking with Battery-Assisted and Battery Charging

Aug 4, 2024 · In this paper, we will study the production of solar energy using a single-axis solar tracker using Arduino. The solar tracker uses Arduino to maximize efficiency while tracking the

Automatic Tracking Solar Street Light Based on Microcontroller

This paper designed an automatic tracking solar lights based on microcontroller, mainly by the solar panels, solar auto-tracking controller, batteries, lights and other components. Through

Design of double axis solar automatic light tracing

Dec 7, 2022 · Therefore, in order to increase the power generation capacity and efficiency of solar power generation, automatic tracking power generation devices should be used to replace

Mobile Charging using Solar Tracking System

Jul 31, 2024 · The use of a solar tracking system for mobile charging is a viable option for providing a sustainable and clean source of power. It is an efficient way to charge mobile

Maximum Power Point Tracking Algorithm for Solar

Jan 8, 2018 · 1 System Description This reference design is a software implementation of a simple MPPT algorithm for a single-cell Li-ion battery charging system with a solar panel input. To

How to Charge Lithium Batteries with Solar Panels?

Jun 13, 2024 · Learn how to charge lithium batteries with solar panels, including battery types, panel selection, and key components for efficient solar charging.

(PDF) Solar tracker design on solar panel for

Dec 1, 2022 · In static solar panels, the time required to fully charge the 12v, 7ah lead acid battery is 5 hours 10 minutes, while using a solar tracker the lead

EO based fuzzy optimal controller for solar MPPT and battery charging

Jan 18, 2025 · The widespread adoption of electric vehicles has faced significant challenges, primarily due to the limited availability of charging infrastructure and the slow charging times

Maximum Power Point Tracking Algorithm for Solar

Jan 8, 2018 · This reference design is a software implementation of a simple MPPT algorithm for a single-cell Li-ion battery charging system with a solar panel input. To maximize the output

Maximum power point tracking and optimal Li-ion battery charging

Sep 1, 2012 · At present, the common MPPT control methods include: (1) voltage feedback method, which obtains the voltage of MPPT of solar cell in a fixed environment; although its

Solar Powered Battery Charging System with Maximum Power Point Tracking

Feb 9, 2018 · Abstract: Ahstract- This paper proposes environmental friendly solar based charging system for battery electric vehicles having lithium ion battery. A DC - DC Cuk converter is used

Solar-Powered Portable Charger Using IoT-Based Technique

Jul 16, 2021 · The automated voltage is tackled by the automatic module transmission which restricts the battery to overcharge and undercharge and helps to last long, thus making the

How to Charge a Lithium Battery with a Solar Panel: A

Nov 16, 2024 · Discover how to effectively charge lithium batteries with solar panels in this comprehensive guide. Learn about the types of lithium batteries, their eco-friendly benefits,

Solar Tracking System with Auto Cut-Off Battery

May 30, 2023 · This project aims to produce energy by maximizing the amount of solar energy that is absorbed, store it in a battery which has auto cut-off circuit to charge the battery, only to

6 FAQs about [Solar automatic tracking lithium battery charging system]

Can a tracked solar panel optimize battery charging?

[Show full abstract] This paper presents the simulation of optimized charging of batteries by means of tracked solar panel. Unmanned exploration vehicles having combination of two rechargeable batteries each performing charging and discharging operation solely.

How long does a solar tracker take to charge a battery?

In static solar panels , the time required to fully charge the 12v, 7ah lead acid battery is 5 hours 10 minutes, while using a solar tracker the lead acid battery charging time is 3 hours 30 minutes. The use of a solar tracker saves battery charging time for 1 hour 40 minutes compared to static solar panels . Content may be subject to copyright.

How does a solar panel charging algorithm work?

The principle of this algorithm relies on monitoring the reflected input power from the solar panel in the form of charging current as the input voltage is manipulated. Similar to the PO method, this is a hill-climbing scheme that selects the operating point that grants the highest battery charging current.

How can a tracking algorithm maximize the output power of a solar panel?

To maximize the output power of the solar panel, a tracking algorithm must have the ability to monitor input power and adjust load impedance, which typically requires extra circuitry and complex firmware.

Which solar charging system is best for Li-ion batteries?

Many previous studies focused on specific system control, whereas the PV charging system proposed by this study integrated the solar MPPT and developed the most efficient charging equipment for the Li-ion battery.

What is a solar power tracker?

This control is based primarily on the assumption that the maximum power point of a solar panel under any given condition is at an operating point equal to a fixed ratio of the open circuit voltage. The voltage ratio selected for designs using this tracker are chosen anywhere between 70% and 80%.

Learn More

- Mobile 220v portable power supply lithium battery charging

- Maximum charging power of lithium battery pack

- Lithium battery pack split charging

- Lithium battery pack charging and discharging balancing machine

- RV lithium battery charging inverter

- How fast is considered fast charging for lithium battery packs

- Charging management of lithium battery pack

- Principle of Solar Automatic Charging Container

- Solar power generation system household lithium battery full set 220v

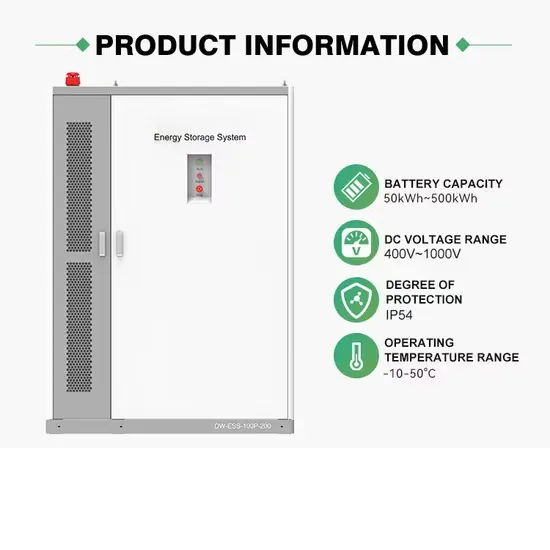

Industrial & Commercial Energy Storage Market Growth

The global industrial and commercial energy storage market is experiencing explosive growth, with demand increasing by over 250% in the past two years. Containerized energy storage solutions now account for approximately 45% of all new commercial and industrial storage deployments worldwide. North America leads with 42% market share, driven by corporate sustainability initiatives and tax incentives that reduce total project costs by 18-28%. Europe follows closely with 35% market share, where standardized industrial storage designs have cut installation timelines by 65% compared to traditional built-in-place systems. Asia-Pacific represents the fastest-growing region at 50% CAGR, with manufacturing scale reducing system prices by 20% annually. Emerging markets in Africa and Latin America are adopting industrial storage solutions for peak shaving and backup power, with typical payback periods of 2-4 years. Major commercial projects now deploy clusters of 15+ systems creating storage networks with 80+MWh capacity at costs below $270/kWh for large-scale industrial applications.

Industrial Energy System Innovations & Cost Benefits

Technological advancements are dramatically improving industrial energy storage performance while reducing costs. Next-generation battery management systems maintain optimal operating conditions with 45% less energy consumption, extending battery lifespan to 20+ years. Standardized plug-and-play designs have reduced installation costs from $85/kWh to $40/kWh since 2023. Smart integration features now allow multiple industrial systems to operate as coordinated energy networks, increasing cost savings by 30% through peak shaving and demand charge management. Safety innovations including multi-stage fire suppression and thermal runaway prevention systems have reduced insurance premiums by 35% for industrial storage projects. New modular designs enable capacity expansion through simple system additions at just $200/kWh for incremental capacity. These innovations have improved ROI significantly, with commercial and industrial projects typically achieving payback in 3-5 years depending on local electricity rates and incentive programs. Recent pricing trends show standard industrial systems (1-2MWh) starting at $330,000 and large-scale systems (3-6MWh) from $600,000, with volume discounts available for enterprise orders.