集装箱储能系统散热及抗震性研究

May 28, 2013 · 关键词: 集装箱式储能系统, 散热, 抗震 Abstract: Containerized energy storage systems integrate all storage components into one or more standard containers. They are

Containerized Energy Storage

Nov 19, 2019 · CanPower containerized energy storage solutions allow flexible installation in various applications including marine, industrial equipment, shore power, renewable and grid.

Designing a BESS Container: A Comprehensive Guide to Battery Energy

Apr 10, 2023 · Discover the essential steps in designing a containerized Battery Energy Storage System (BESS), from selecting the right battery technology and system architecture to

Park energy storage container layout planning

rage system (BESS) container design sequence? The Battery Energy Storage System (BESS) container design sequence is a series of steps that outline the design and develop. ent of a

BATTERY ENERGY STORAGE SYSTEM CONTAINER, BESS

Apr 8, 2024 · Battery Energy Storage System (BESS) is a containerized solution that is designed to store and manage energy generated from renewable sources such as solar and wind power.

5MWh Containerized Energy Storage System

Design advantage(Containerized Energy Storage System): 1. Comprehensively real-time monitoring of safety risk points such as cell, connector, busbar and electrical parts 2. Design of

Simulation analysis and optimization of containerized energy storage

Sep 10, 2024 · This study analyses the thermal performance and optimizes the thermal management system of a 1540 kWh containerized energy storage battery system using CFD

Containerized Energy Storage System

Our containerized energy storage system is composed of a battery enclosure, a cooling system, a fire suppression system, a battery management system and local controllers. It offers energy

Development of Containerized Energy Storage System

Dec 24, 2014 · Our company has been developing a containerized energy storage system by installing a varyingly utilizable energy storage system in a container from 2010. The module

Containerized Energy Storage: Scalable, Flexible, and

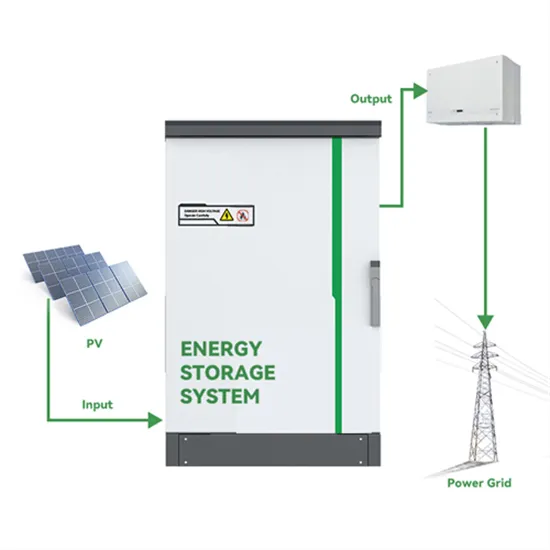

Aug 12, 2025 · What is a Containerized Energy Storage System? A Containerized Energy Storage System integrates battery modules, power conversion systems, and control equipment into a

Containerized Energy Storage System Complete battery

Mar 21, 2024 · What is containerized ESS? y storage system is a complete, self-contained battery solution for large-scale marine energy storage. The batteries and all control, interface, and

Energy storage battery system container design

Energy storage battery system container design A Battery Energy Storage System (BESS) significantly enhances power system flexibility, especially in the context of integrating

Containerized energy storage systems

Mar 16, 2024 · What is containerized ESS? ABB''s containerized energy storage system is a complete, self-contained battery solution for large-scale marine energy storage. The batteries

Designing a BESS Container: A Comprehensive Guide to Battery Energy

Apr 10, 2023 · The Battery Energy Storage System (BESS) container design sequence is a series of steps that outline the design and development of a containerized energy storage system.

Current Trends and Developments in Containerized Energy Storage Systems

Feb 5, 2024 · Containerized energy storage systems are revolutionizing the energy sector by offering flexible, scalable, and cost-effective solutions for energy storage needs. AlphaESS,

Simulation analysis and optimization of containerized energy storage

Sep 10, 2024 · Abstract The air-cooling system is of great significance in the battery thermal management system because of its simple structure and low cost. This study analyses the

Design Specifications for Containerized Energy Storage

All-in-one design complete with battery, PCS, HVAC, fire suppression, and smart controller EVESCO''''s ES-250400-NA is an all-in-one containerized energy storage system that creates

Containerized Energy Storage System: Structure and

As an efficient and convenient energy storage solution, the containerized energy storage system not only offers modularity and plug-and-play advantages but also achieves efficient energy use

Park energy storage container layout planning

What is a battery energy storage system (BESS) container design sequence? The Battery Energy Storage System (BESS) container design sequence is a series of steps that outline the design

Container Energy Storage System: All You Need to Know

Apr 23, 2024 · Containerized energy storage systems bring a plethora of advantages to the table, making them an increasingly popular choice for energy storage applications. From their

Container energy storage system design

The Battery Energy Storage System (BESS) container design sequence is a series of steps that outline the design and development of a containerized energy storage system. This system is

Numerical investigation on explosion hazards of lithium-ion

Nov 1, 2023 · Numerical investigation on explosion hazards of lithium-ion battery vented gases and deflagration venting design in containerized energy storage system

6 FAQs about [Containerized energy storage system design]

What is a containerized energy storage battery system?

The containerized energy storage battery system comprises a container and air conditioning units. Within the container, there are two battery compartments and one control cabinet. Each battery compartment contains 2 clusters of battery racks, with each cluster consisting of 3 rows of battery racks.

What is a battery energy storage system (BESS) container design sequence?

The Battery Energy Storage System (BESS) container design sequence is a series of steps that outline the design and development of a containerized energy storage system. This system is typically used for large-scale energy storage applications like renewable energy integration, grid stabilization, or backup power.

Can CFD simulation be used in containerized energy storage battery system?

Therefore, we analyzed the airflow organization and battery surface temperature distribution of a 1540 kWh containerized energy storage battery system using CFD simulation technology. Initially, we validated the feasibility of the simulation method by comparing experimental results with numerical ones.

What is a containerized storage battery compartment?

The containerized storage battery compartment is separated by a bulkhead to form two small battery compartments with a completely symmetrical arrangement. The air-cooling principle inside the two battery compartments is exactly the same.

Does ABB offer a containerized energy storage system?

ABB’s Containerized Energy Storage System is suitable for a wide variety of shipsabb.com/marine—We re erve the right to make technical changes or modify the contents of this document without prior notice. With re-gard to purchase orders, the agreed par-ticulars shall prevail. ABB AG does not ac-cep

What is an energy storage system?

This system is typically used for large-scale energy storage applications like renewable energy integration, grid stabilization, or backup power. Here's an overview of the design sequence:

Learn More

- Azerbaijan containerized energy storage power station manufacturer

- Energy storage new energy appearance design

- Intelligent energy storage product design

- Design of wind and solar energy storage power station

- Swiss new energy storage site design

- Seoul Energy Storage Container Design Factory Operation

- Distributed energy storage power station size design

- Design of outdoor energy storage power station

- Cyprus Energy Storage Power Station New Energy Engineering Design Plan

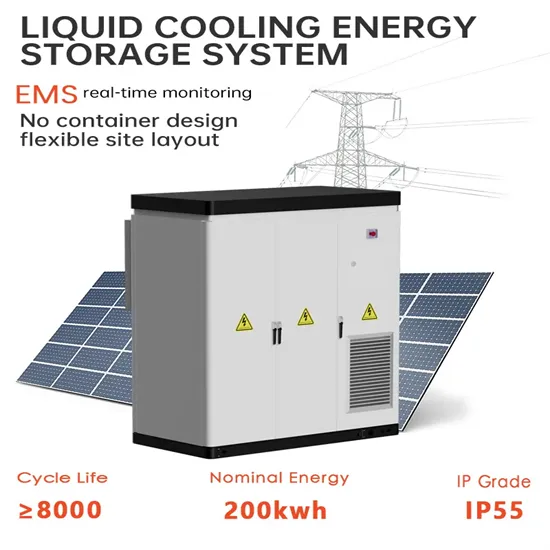

Industrial & Commercial Energy Storage Market Growth

The global industrial and commercial energy storage market is experiencing explosive growth, with demand increasing by over 250% in the past two years. Containerized energy storage solutions now account for approximately 45% of all new commercial and industrial storage deployments worldwide. North America leads with 42% market share, driven by corporate sustainability initiatives and tax incentives that reduce total project costs by 18-28%. Europe follows closely with 35% market share, where standardized industrial storage designs have cut installation timelines by 65% compared to traditional built-in-place systems. Asia-Pacific represents the fastest-growing region at 50% CAGR, with manufacturing scale reducing system prices by 20% annually. Emerging markets in Africa and Latin America are adopting industrial storage solutions for peak shaving and backup power, with typical payback periods of 2-4 years. Major commercial projects now deploy clusters of 15+ systems creating storage networks with 80+MWh capacity at costs below $270/kWh for large-scale industrial applications.

Industrial Energy System Innovations & Cost Benefits

Technological advancements are dramatically improving industrial energy storage performance while reducing costs. Next-generation battery management systems maintain optimal operating conditions with 45% less energy consumption, extending battery lifespan to 20+ years. Standardized plug-and-play designs have reduced installation costs from $85/kWh to $40/kWh since 2023. Smart integration features now allow multiple industrial systems to operate as coordinated energy networks, increasing cost savings by 30% through peak shaving and demand charge management. Safety innovations including multi-stage fire suppression and thermal runaway prevention systems have reduced insurance premiums by 35% for industrial storage projects. New modular designs enable capacity expansion through simple system additions at just $200/kWh for incremental capacity. These innovations have improved ROI significantly, with commercial and industrial projects typically achieving payback in 3-5 years depending on local electricity rates and incentive programs. Recent pricing trends show standard industrial systems (1-2MWh) starting at $330,000 and large-scale systems (3-6MWh) from $600,000, with volume discounts available for enterprise orders.