seoul tram energy storage clean energy storage station factory

Long-Duration Energy Storage to Support the Grid of the Future Through investments and ongoing initiatives like DOE''''s Energy Storage Grand Challenge—which draws on the

Energy storage container design solution

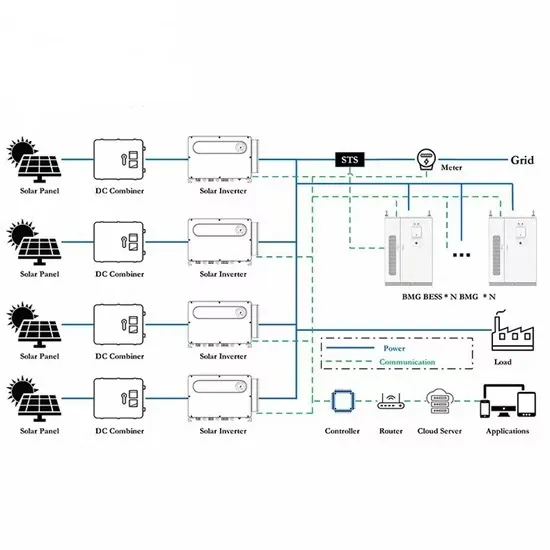

This article introduces the structural design and system composition of energy storage containers, focusing on its application advantages in the energy field. As a flexible and mobile energy

north korea energy storage container sales factory is running

About north korea energy storage container sales factory is running - Suppliers/Manufacturers As the photovoltaic (PV) industry continues to evolve, advancements in north korea energy

Suva smart energy storage cabinet design factory

The following are several key design points: Modular design: The design of the energy storage cabinet should adopt a modular structure to facilitate expansion, maintenance and

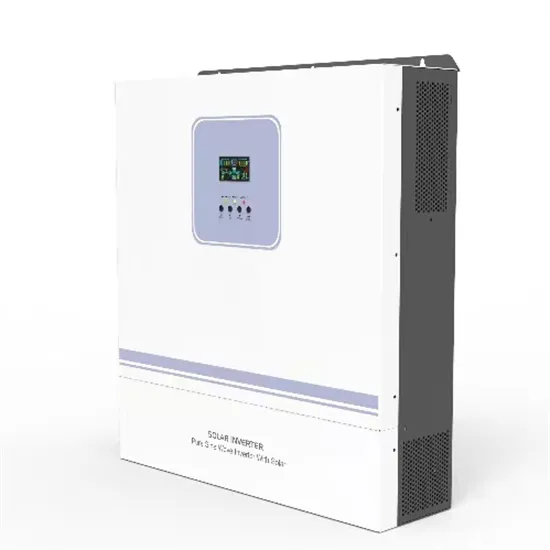

BATTERY ENERGY STORAGE SYSTEMS

Nov 9, 2022 · Sinovoltaics advice: we suggest having the logistics company come inspect your Battery Energy Storage System at the end of manufacturing, in order for them to get

Design of Seoul Energy Storage Container Park: Powering

Dec 23, 2020 · Ever wondered how a mega-city like Seoul keeps its lights on while slashing carbon footprints? Meet the game-changer: the Seoul Energy Storage Container Park. This

Seoul Energy Storage Container Manufacturing Company

Top Energy Storage Manufacturers in South Korea The company, based in Seoul, has a diversified product portfolio that includes Energy Storage Inverters, Energy Storage Battery

Seoul Container Energy Storage Company: Powering the

Feb 15, 2025 · Look no further than container energy storage systems (CESS) – the unsung heroes revolutionizing renewable energy adoption. As South Korea pushes toward carbon

Seoul energy storage full case design

ioritized sustainable energy storage. To promote sustainable energy use, energy storage systems are being deployed to creation, as a result of the project. Seoul expects $1.4 billion in

seoul energy storage container office

SolarEdge opens 2GWh lithium battery cell factory in South Korea Smart energy optimisation and management tech company SolarEdge has begun producing test cells for certification at its

Seoul nicd battery energy storage container supplier

South Korea is a global leader in battery technology,particularly in the development and manufacturing of lithium-ion batteries,which are crucial for electric vehicles (EVs) and energy

seoul energy storage container power plant factory is in operation

The First Commercial Sand-based Thermal Energy Storage in the World Is in Operation – BBC News Visited Polar Night Energy — Polar Night Energy Polar Night Energy''''s first commercial

Seoul energy storage company factory operation

When you''''re looking for the latest and most efficient seoul energy storage company factory operation requirements for your PV project, our website offers a comprehensive selection of

seoul tram energy storage clean energy storage station factory

The field of solar panels with an energy storage station located in the middle of a solar cell panel on an area of hundreds of acres 3d rendering energy storage system or battery container units

Seoul energy storage manufacturing plant in operation

seoul energy storage machinery design factory operation position Energy storage and microgrid technology solutions company, Saft, has opened a new factory in Zuhai, China, dedicated to

iraq energy storage container design factory operation

Design and Operation of Automated Container Storage Systems The first work covering all aspects of planning and optimising automated container storage systems; Includes over 50

Design of Seoul Energy Storage Container Park: Powering

Dec 23, 2020 · Meet the game-changer: the Seoul Energy Storage Container Park. This article is your backstage pass for: Fun fact: Seoul''s energy storage capacity could charge 1.2 million

list of seoul energy storage container companies

List of Container Storage companies in South Korea We are a company based Korea with manufacture well-being food container, sanitation cutting board related Telephone: 82-70

Where is the seoul energy storage factory

The Korea Energy Terminal, located 308 kilometers south of Seoul, has begun its commercial operation with a total capacity to store oil and gas equivalent to 4.4 million barrels, according

Seoul energy storage control cabinet

A battery energy storage system (BESS) is well defined by its name. It is a means for storing electricity in a system of batteries for later use. As a system, BESSs are typically a collection

Seoul Energy Storage System Container: Powering the

And here''s the kicker - Seoul''s container-based solutions aren''t just metal boxes with batteries. They''re the Swiss Army knives of energy management, blending smart grid integration with

Designing a BESS Container: A Comprehensive Guide to Battery Energy

Apr 10, 2023 · The Battery Energy Storage System (BESS) container design sequence is a series of steps that outline the design and development of a containerized energy storage system.

north korea energy storage container manufacturing company

Wholesale Energy Storage Manufacturers in South Korea The company, based in Seoul, has a diversified product portfolio that includes Energy Storage Inverters, Energy Storage Battery

ENERGY STORAGE & ENERGY SAVING SOLUTIONS

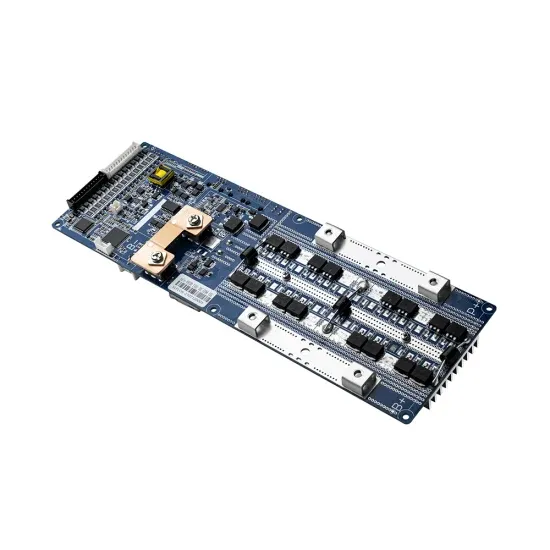

Nov 6, 2024 · Design Principle Power line Communication AC/DC converters, energy storage containers, and DC/DC power modules connected through 700V/1500V DC bus coupling; the

5 FAQs about [Seoul Energy Storage Container Design Factory Operation]

When does an energy storage project start?

“The operations and maintenance phase of an en- ergy storage project begins when the system has been successfully commissioned and the owner has obtained approval to operate the system.

Does container manufacturing take a lot of space?

Container manufacturing can take (a lot of) space. If your project requires a 40ft container, your contain- er manufacturing will probably take place outdoors. During that step, several points need to be looked at: • Manufacturing environment: no clean room re- quired here, but is there any risk of electrocution following a heavy rain?

Do battery energy storage systems look like containers?

C. Container transportation Even though Battery Energy Storage Systems look like containers, they might not be shipped as is, as the logistics company procedures are constraining and heavily standardized. BESS from selection to commissioning: best practices38 Firstly, ensure that your Battery Energy Storage System dimensionsare standard.

How are battery energy storage systems transported?

Given the Battery Energy Storage System’s dimen- sions, BESS are usually transported by sea to their destination country (if trucking is not an option), and then by truck to their destination site. A.Logistics The consequence is that the shipment process can be worrisome.

What should be included in a contract for an energy storage system?

Several points to include when building the contract of an Energy Storage System: • Description of components with critical tech- nical parameters:power output of the PCS, ca- pacity of the battery etc. • Quality standards:list the standards followed by the PCS, by the Battery pack, the battery cell di- rectly in the contract.

Learn More

- The latest operation information of energy storage container factory

- Mongolia Energy Storage Container Factory Operation

- Pakistan electrical energy storage container factory is in operation

- Energy storage container charging station design

- Bucharest container energy storage professional factory

- Manila container energy storage professional factory

- Design of Capital Energy Storage Container Power Station

- Nairobi Energy Storage Container Distribution Box Factory

- How much is the Ecuadorian energy storage container factory per square meter

Industrial & Commercial Energy Storage Market Growth

The global industrial and commercial energy storage market is experiencing explosive growth, with demand increasing by over 250% in the past two years. Containerized energy storage solutions now account for approximately 45% of all new commercial and industrial storage deployments worldwide. North America leads with 42% market share, driven by corporate sustainability initiatives and tax incentives that reduce total project costs by 18-28%. Europe follows closely with 35% market share, where standardized industrial storage designs have cut installation timelines by 65% compared to traditional built-in-place systems. Asia-Pacific represents the fastest-growing region at 50% CAGR, with manufacturing scale reducing system prices by 20% annually. Emerging markets in Africa and Latin America are adopting industrial storage solutions for peak shaving and backup power, with typical payback periods of 2-4 years. Major commercial projects now deploy clusters of 15+ systems creating storage networks with 80+MWh capacity at costs below $270/kWh for large-scale industrial applications.

Industrial Energy System Innovations & Cost Benefits

Technological advancements are dramatically improving industrial energy storage performance while reducing costs. Next-generation battery management systems maintain optimal operating conditions with 45% less energy consumption, extending battery lifespan to 20+ years. Standardized plug-and-play designs have reduced installation costs from $85/kWh to $40/kWh since 2023. Smart integration features now allow multiple industrial systems to operate as coordinated energy networks, increasing cost savings by 30% through peak shaving and demand charge management. Safety innovations including multi-stage fire suppression and thermal runaway prevention systems have reduced insurance premiums by 35% for industrial storage projects. New modular designs enable capacity expansion through simple system additions at just $200/kWh for incremental capacity. These innovations have improved ROI significantly, with commercial and industrial projects typically achieving payback in 3-5 years depending on local electricity rates and incentive programs. Recent pricing trends show standard industrial systems (1-2MWh) starting at $330,000 and large-scale systems (3-6MWh) from $600,000, with volume discounts available for enterprise orders.