Maximum power point tracking in solar pump inverter

Mar 22, 2025 · Maximum Power Point Tracking (MPPT) technology is a critical component in enhancing the efficiency of solar-powered water pump systems. In essence, MPPT technology

Maximum Power Point Tracking of Solar Water Pumping

Dec 2, 2023 · In this paper, the Fuzzy Logic Controller (FLC) approach for achieving maximum power point tracking (MPPT) in a solar photovoltaic (PV) array-based water pumping system

CHF100 Frequency MPPT Solar Pump Inverter with Vector

CHF100 Product Description: One of the standout features of this solar pump inverter is its MPPT function, which ensures that the inverter always operates at its maximum power point,

Maximizing Water Flow with MPPT Solar Pump Inverters

4 days ago · Conclusion Maximizing water flow in solar water pumping systems is essential for agricultural productivity and water security. MPPT solar pump inverters play a crucial role in

How MPPT VFD solar pump inverters differ from standard VFDs

Dec 30, 2024 · MPPT VFD solar pump inverters are specialized devices designed specifically for solar applications and differ significantly from standard variable frequency drives (VFDs). 1.

A three-phase PV-pump inverter with maximum power point tracking (MPPT

Jun 28, 2016 · The objective of this paper presents a photovoltaic (PV) water pumping system with a maximum power point tracking (MPPT). The water pumping system uses a variable

Design and Development of a Solar PV Inverter for

Mar 8, 2022 · The inverter can be operated in two modes – the former, using MPPT (Maximum power Point Tracking) technique, wherein the dc-dc converter is controlled in such a way that

Understanding the Science Behind MPPT Solar Pump Inverters

3 days ago · Introduction: In the realm of sustainable energy, solar pumping technologies have emerged as game-changers, revolutionizing access to water in remote areas. At the heart of

What Is MPPT in a Solar Inverter? How It Works & Why It

Jul 27, 2025 · Introduction In the realm of solar energy systems, the term MPPT, or Maximum Power Point Tracking, emerges as a pivotal concept. While it may seem arcane to the

Design and Implementation of MPPT Fuzzy Logic Controller for Inverter

5 days ago · The use of MPPT FLC, when connected to a Water Pump, has an average total water flow more than without MPPT with a ratio of 1.58: 1 so that the use of MPPT with the

How Solar Pump Inverters Improve Water System

Aug 1, 2025 · Advantages Over Traditional Systems A solar pump inverter eliminates the need for grid power or diesel generators, reducing operational costs and maintenance. It integrates

The Role of Automation in Modern Three-Phase Solar Pump Inverters

3 days ago · Maximum Power Point Tracking (MPPT): Automation algorithms incorporated into solar pump inverters employ sophisticated MPPT techniques. These algorithms continuously

yemen solar pump inverter | Solar Energy Products

CT112 soalr pump inverter is applied in solar pump system,it converts DC power from solar PV array to AC power to run pump motors verter controls the system operation and adjust the

The Ultimate Guide to Inverter Pump Solar Systems

5 days ago · Energy Efficiency: Inverter technology optimizes pump operation, minimizing energy consumption and maximizing water output. Maximum Power Usage: MPPT (Maximum Power

Improving photovoltaic water pumping system performance

May 8, 2025 · PSO-Based MPPT Controller: The proposed PSO-based Maximum Power Point Tracking (MPPT) controller is designed to maximize the energy extraction from the

6 FAQs about [MPPT Maximum Power Tracking Water Pump Inverter]

Can a MPPT-bat improve the efficiency of solar water pumping systems?

Mathematics. 2024;12: 594. This paper investigates enhancing the efficiency of solar water pumping systems (SWPS) by implementing a Maximum Power Point Tracking technique based on the Bat Metaheuristic Optimizer (MPPT-bat) for the photovoltaic generator (PVG) side, coupled with Direct Torque Control (DTC) for the induction motor powering the pump.

What is maximum power point tracking (MPPT)?

In response, various maximum power point tracking (MPPT) techniques are explored to optimize power generation. The study focuses on three MPPT techniques—perturb and observe, incremental conductance, and the beta method—in the context of solar water pump systems.

Can ML-based maximum power point tracking (MPPT) be used in solar power systems?

By performing a thorough analysis of Machine Learning (ML)-based Maximum Power Point Tracking (MPPT) approaches, which are useful for obtaining maximum power in solar power systems, Refs. 27 and 28 add more to the body of research.

What are the different MPPT settings for solar water pump system?

Rotor speed and electromagnetic torque of the solar water pump system under three different MPPT settings: (a) P and O MPPT, (b) IC MPPT, and (c) beta MPPT. In the evaluation of the three MPPT methods [Perturb and Observe (P and O), Incremental Conductance (IC), and beta] for a solar water pump system, the following key findings have been observed:

What does MPPT stand for?

It consists of an autonomous solar array, an essential DC–DC boosting converter, a three-phase Voltage Source Inverter (VSI), and an induction motor coupled to a centrifugal pump that circulates water. This combined system functions as the testing ground for three different Maximum Power Point Tracking (MPPT) techniques.

Is beta MPPT a good choice for solar water pump system?

The beta MPPT method not only achieves the desired operating points efficiently but also contributes to a more stable and reliable operation of the solar water pump system. In summary, the beta MPPT method is suggested as the most suitable choice for optimizing the performance of the solar water pump system.

Learn More

- High Power Solar Water Pump

- Tskhinvali photovoltaic water pump inverter wholesale

- Water pump inverter single phase

- Outdoor power supply for water pump

- How big a water pump should I add to a 2kw inverter

- Single-phase inverter maximum power

- Southeast Asian water pump inverter manufacturer

- Conakry inverter power

- Solar high power off-grid inverter

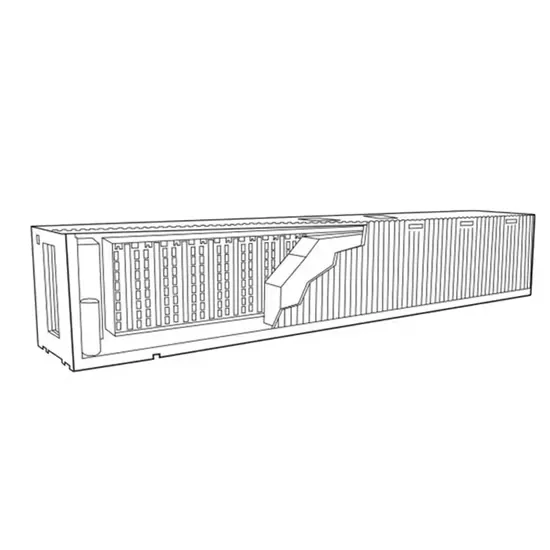

Industrial & Commercial Energy Storage Market Growth

The global industrial and commercial energy storage market is experiencing explosive growth, with demand increasing by over 250% in the past two years. Containerized energy storage solutions now account for approximately 45% of all new commercial and industrial storage deployments worldwide. North America leads with 42% market share, driven by corporate sustainability initiatives and tax incentives that reduce total project costs by 18-28%. Europe follows closely with 35% market share, where standardized industrial storage designs have cut installation timelines by 65% compared to traditional built-in-place systems. Asia-Pacific represents the fastest-growing region at 50% CAGR, with manufacturing scale reducing system prices by 20% annually. Emerging markets in Africa and Latin America are adopting industrial storage solutions for peak shaving and backup power, with typical payback periods of 2-4 years. Major commercial projects now deploy clusters of 15+ systems creating storage networks with 80+MWh capacity at costs below $270/kWh for large-scale industrial applications.

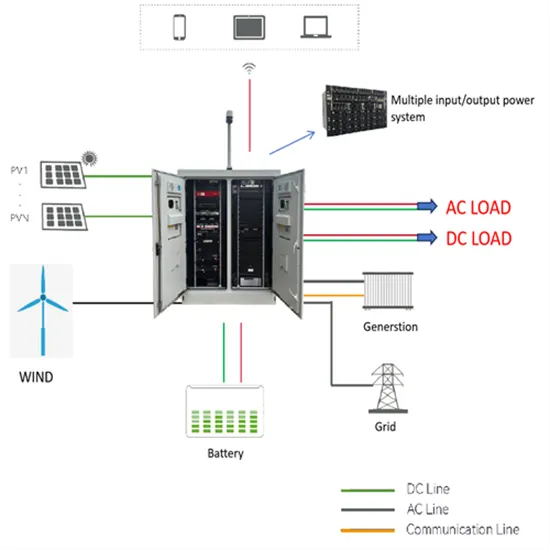

Industrial Energy System Innovations & Cost Benefits

Technological advancements are dramatically improving industrial energy storage performance while reducing costs. Next-generation battery management systems maintain optimal operating conditions with 45% less energy consumption, extending battery lifespan to 20+ years. Standardized plug-and-play designs have reduced installation costs from $85/kWh to $40/kWh since 2023. Smart integration features now allow multiple industrial systems to operate as coordinated energy networks, increasing cost savings by 30% through peak shaving and demand charge management. Safety innovations including multi-stage fire suppression and thermal runaway prevention systems have reduced insurance premiums by 35% for industrial storage projects. New modular designs enable capacity expansion through simple system additions at just $200/kWh for incremental capacity. These innovations have improved ROI significantly, with commercial and industrial projects typically achieving payback in 3-5 years depending on local electricity rates and incentive programs. Recent pricing trends show standard industrial systems (1-2MWh) starting at $330,000 and large-scale systems (3-6MWh) from $600,000, with volume discounts available for enterprise orders.