Energy Storage System Cooling

May 5, 2025 · Background Energy storage systems (ESS) have the power to impart flexibility to the electric grid and offer a back-up power source. Energy storage systems are vital when

How much energy can a container store

Aug 16, 2023 · How much energy can be stored in a 20-feet liquid cooling container? itional design of 3727kWh to 5016kWh. Higher BESS capacity will allow for lower auxiliary power

Efficient Cooling System Design for 5MWh BESS Containers:

Aug 10, 2024 · In conclusion, designing an efficient cooling system for 5MWh BESS containers is essential to ensure optimal performance, safety, and longevity of the battery cells. By

Compressed Air Energy Storage

In diabatic compressed air energy storage systems, off-peak electricity is transformed into energy potential for compressed air, and kept in a cavern, but given out when demand is high. Fig. 17

Cooling Costs

Aug 23, 2022 · The selection of a data center''s location — and subsequently its outside climate — will impact how much energy its cooling system will require for adequate heat transfer to

Integrated cooling system with multiple operating modes for

Apr 15, 2025 · For conventional air conditioning, the average energy consumption of the cooling system accounts for nearly 6 % of the energy storage, of which the average energy

Review on operation control of cold thermal energy storage in cooling

Jun 1, 2025 · The integration of cold energy storage in cooling system is an effective approach to improve the system reliability and performance. This review provides an overview and recent

A thermal management system for an energy storage battery container

May 1, 2023 · The existing thermal runaway and barrel effect of energy storage container with multiple battery packs have become a hot topic of research. This paper innovatively proposes

Reefer Container Power Consumption Per Hour: Key Insights

Understanding Reefer Container Power Consumption To truly grasp the concept of reefer container power consumption, we''ll first need to understand what a reefer container is. It''s

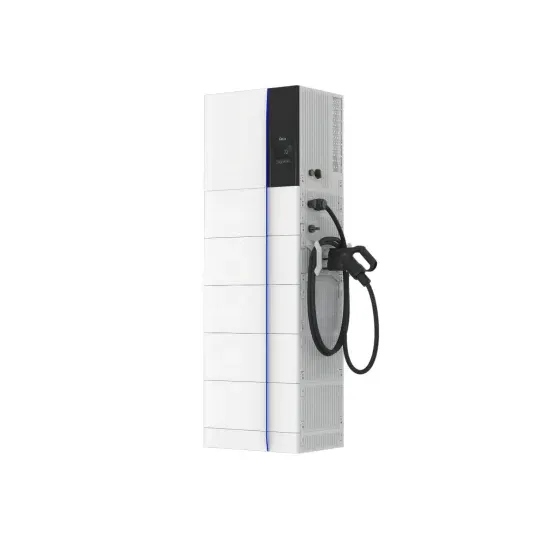

Containerized Energy Storage System Complete battery

Mar 21, 2024 · What is containerized ESS? ABB''s containerized energy storage system is a complete, self-contained battery solution for large-scale marine energy storage. The batteries

Data centers cooling: A critical review of techniques,

Apr 1, 2024 · In order to increase data centers'' efficiency and performance, a proper cooling system should be applied. This article provides a comprehensive assessment which explores

Energy storage cooling system

Dec 8, 2024 · Through intensive design and the application of large-capacity batteries, the footprint of liquid-cooled energy storage products can save more than 50% compared with

Energy Storage System Cooling

May 5, 2025 · Energy storage systems (ESS) have the power to impart flexibility to the electric grid and offer a back-up power source. Energy storage systems are vital when municipalities

Air Conditioning with Thermal Energy Storage

Mar 14, 2023 · Thermal Energy Storage (TES) for space cooling, also known as cool storage, chill storage, or cool thermal storage, is a cost saving technique for allowing energy-intensive,

Liquid cooling vs air cooling

Aug 24, 2023 · Studies have shown that the energy consumption of forced air-cooled energy storage equipment can be reduced by about 20% by using technologies such as reasonable

Designing a BESS Container: A Comprehensive Guide to Battery Energy

Apr 10, 2023 · The Battery Energy Storage System (BESS) container design sequence is a series of steps that outline the design and development of a containerized energy storage system.

How much energy can a container store

Aug 16, 2023 · Energy Storage Container. Adding Containerized Battery Energy Storage System (BESS) to solar, wind, EV charger, and other renewable energy applications can reduce

6 FAQs about [How much electricity does the energy storage container need for air cooling system]

Does cool storage reduce energy consumption?

Cool storage will reduce the average cost of energy consumed and can potentially reduce the energy consumption and initial capital cost of a cooling system compared to a conventional cooling system without cool storage.

What is thermal energy storage for space cooling?

Thermal Energy Storage (TES) for space cooling, also known as cool storage, chill storage, or cool thermal storage, is a cost saving technique for allowing energy-intensive, electrically driven cooling equipment to be predominantly operated during off-peak hours when electricity rates are lower.

How many chillers does an ice storage system use?

Most ice storage systems utilize two chillers in addition to the ice storage equipment. Two chillers provide approximately 60% of the required cooling on a design day while the ice storage provides the remaining 40% of the cooling capacity.

Why are energy storage systems important?

Energy storage systems (ESS) have the power to impart flexibility to the electric grid and offer a back-up power source. Energy storage systems are vital when municipalities experience blackouts, states-of-emergency, and infrastructure failures that lead to power outages.

What is the minimum storage volume for chilled water?

The practical minimum storage volume for chilled water is approximately 10.7cubic feet per ton-hour at a 20°F temperature difference. There are two basic types - Ice Building Systems (static systems) and Ice Harvesting Systems (dynamic systems).

How do you choose a chiller for ice storage?

For chilled water or ice storage systems, designers select chillers based on the “Ton-hours” of cooling required. A theoretical cooling load of 100 tons maintained for 10 hours corresponds to 1000 ton-hour cooling load. One of the design challenges of thermal storage is to develop an accurate cooling load profile of the project.

Learn More

- Energy storage container battery rack air duct installation

- How is the Latvian energy storage container factory

- How much electricity does an energy storage project usually generate

- Brussels Liquid Cooling Energy Storage Container Quote

- How much electricity can distributed energy storage store

- How many liquid cooling energy storage manufacturers are there in New Zealand

- How many tons does a standard energy storage container weigh

- How much voltage does the energy storage container have

- Liquid Cooling Container Energy Storage System ESS Power Base Station

Industrial & Commercial Energy Storage Market Growth

The global industrial and commercial energy storage market is experiencing explosive growth, with demand increasing by over 250% in the past two years. Containerized energy storage solutions now account for approximately 45% of all new commercial and industrial storage deployments worldwide. North America leads with 42% market share, driven by corporate sustainability initiatives and tax incentives that reduce total project costs by 18-28%. Europe follows closely with 35% market share, where standardized industrial storage designs have cut installation timelines by 65% compared to traditional built-in-place systems. Asia-Pacific represents the fastest-growing region at 50% CAGR, with manufacturing scale reducing system prices by 20% annually. Emerging markets in Africa and Latin America are adopting industrial storage solutions for peak shaving and backup power, with typical payback periods of 2-4 years. Major commercial projects now deploy clusters of 15+ systems creating storage networks with 80+MWh capacity at costs below $270/kWh for large-scale industrial applications.

Industrial Energy System Innovations & Cost Benefits

Technological advancements are dramatically improving industrial energy storage performance while reducing costs. Next-generation battery management systems maintain optimal operating conditions with 45% less energy consumption, extending battery lifespan to 20+ years. Standardized plug-and-play designs have reduced installation costs from $85/kWh to $40/kWh since 2023. Smart integration features now allow multiple industrial systems to operate as coordinated energy networks, increasing cost savings by 30% through peak shaving and demand charge management. Safety innovations including multi-stage fire suppression and thermal runaway prevention systems have reduced insurance premiums by 35% for industrial storage projects. New modular designs enable capacity expansion through simple system additions at just $200/kWh for incremental capacity. These innovations have improved ROI significantly, with commercial and industrial projects typically achieving payback in 3-5 years depending on local electricity rates and incentive programs. Recent pricing trends show standard industrial systems (1-2MWh) starting at $330,000 and large-scale systems (3-6MWh) from $600,000, with volume discounts available for enterprise orders.