Energy Storage Container System Installation: A Step-by

As renewable energy capacity grows 18% year-over-year globally, energy storage container systems have become the linchpin of modern power solutions. These modular units combine

BATTERY ENERGY STORAGE SYSTEM CONTAINER, BESS

Apr 8, 2024 · TLS OFFSHORE CONTAINERS /TLS ENERGY Battery Energy Storage System (BESS) is a containerized solution that is designed to store and manage energy generated

DESIGNING AN HVAC SYSTEM FOR A BESS CONTAINER:

Jun 8, 2023 · The Battery Energy Storage System (BESS) is a versatile technology, crucial for managing power generation and consumption in a variety of applications. Within these

Container battery energy storage ventilation

The Battery Energy Storage System (BESS) is a versatile technology,crucial for managing power generation and consumption in a variety of applications. Within these systems,one key

Container energy storage air duct design

The utility model discloses an air duct improved energy storage container, which comprises a container, an air conditioner, an air duct and a battery rack, wherein the air conditioner, the air

A STEP BY STEP GUIDE ON INSTALLING RACK AND AIR DUCT IN A BESS CONTAINER

How to install the battery rack in the energy storage container Follow these steps to install the racks properly:Position the racks: Based on your layout plan, position the racks within the

Energy storage container with adjustable air duct baffle and

A technology of containers and air ducts, applied in the field of energy storage containers and its regulation, can solve the problems of high battery module temperature, uneven air supply, and

What is the air duct design of energy storage container

Energy Storage Container is an energy storage battery system, which includes a monitoring system, battery management unit, particular fire protection system, special air conditioner,

Energy storage battery container installation process

A battery storage installation is a type of energy storage system where batteries held in containers store electrical energy, deferring the consumption of the stored electricity to a later time.

Energy storage container battery rack air duct

Airflow reorganization and thermal management in a large-space battery The present paper numerically investigates the air-cooling thermal management in a large space energy storage

Energy storage battery cabinet air duct

Challenge. Fueled by an increasing desire for renewable energies and battery storage capabilities, many Utilities are considering significantly increasing their investments in battery

Air duct improved energy storage container

The utility model discloses an air duct improved energy storage container, which comprises a container, an air conditioner, an air duct and a battery rack, wherein the air conditioner, the air

HOW BIG IS THE AIR DUCT DESIGN OF THE ENERGY

Here''s how to install air ducts Energy Storage Container integrated design for easy delivery; Control the cooling and heating system of the air conditioner through thermal management

Energy storage container air duct installation

About Energy storage container air duct installation Here''s how to install air ducts effectively:Identify the airflow path: Determine the direction of airflow within the container.

Energy Storage Air Cooling Cabinet Installation: A Step-by

Jul 20, 2019 · Modern energy storage systems generate enough heat to bake cookies – seriously, some battery racks operate at 40-50°C. That''s where our star player enters: the air cooling

Forced air-cooling technology is mature, and air

Feb 27, 2023 · The main point of the design of forced air-cooling technology is to control the air duct to change the wind speed: due to the different energy

Installation process of energy storage container

A battery energy storage system (BESS) captures energy from renewable and non-renewable sources and stores it in rechargeable batteries (storage devices) for later use. A battery is a

Simulation analysis and optimization of containerized energy storage

Sep 10, 2024 · The air-cooling system is of great significance in the battery thermal management system because of its simple structure and low cost. This study analyses the thermal

Eaton xStorage Container Containerized energy storage

Sep 4, 2024 · Eaton xStorage is now available in a containerized version. This all-in-one, ready-to-use solution is the perfect choice for energy st. rage applications in commercial and

Airflow reorganization and thermal management in a large-space battery

Nov 1, 2024 · The present paper numerically investigates the air-cooling thermal management in a large space energy storage container in which packs of high-power density batteries are

6 FAQs about [Energy storage container battery rack air duct installation]

Is Eaton xstorage a containerized energy storage system?

nerContainerized energy storage systemAll-in-one containe Eaton xStorage is now available in a containerized version. This all-in-one, ready-to-use solution is the perfect choice for energy st

What are the challenges in designing a battery energy storage system container?

The key challenges in designing the battery energy storage system container included: Weight Reduction: The container design had to be lightweight yet strong enough to withstand operational stresses like shocks and seismic forces, ensuring the batteries were protected during transport and deployment.

How many mw can a battery energy storage system handle?

the load when needed, reducing the use of diesel generators. The battery energy storage system can also be used continuously to .6 MWh1.1 MW / 1.2 MWhBattery warran ISO container. 2590 mm and other high humidi y/ corrosive applicationsFire alarmIncluded as standa

How do I integrate an efficient HVAC system into the container design?

We integrated an efficient HVAC system into the container design by: Incorporating two AC chillers to cool the battery area, regulating the temperature inside the container. Installing two mounted fans on top of the transformer block to circulate the air and ensure efficient heat dissipation.

How to optimize battery storage system performance and safety?

To ensure optimal performance and safety of battery storage system, effective thermal management was a key consideration in the design. We integrated an efficient HVAC system into the container design by: Incorporating two AC chillers to cool the battery area, regulating the temperature inside the container.

How safe is a battery storage container?

Static simulations confirmed the container could safely handle expected operational stresses. The integrated HVAC system maintained the batteries' ideal temperature, improving durability and preventing overheating or freezing. The container was also weatherproof, offering protection against environmental elements.

Learn More

- Lithium-ion battery energy storage container installation in Antananarivo

- Swedish container energy storage lithium battery installation

- Aluminum alloy battery energy storage container installation in Kosovo

- Energy storage battery container application scenarios

- Installation of energy storage battery charging pile

- Fiji Battery Energy Storage Container

- Flow battery energy storage container fire protection system

- Energy storage cabinet battery display rack

- Liquid-cooled energy storage battery cabinet installation in Portugal

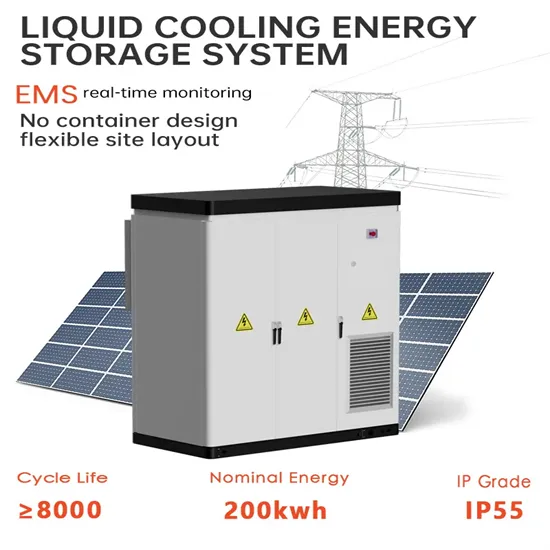

Industrial & Commercial Energy Storage Market Growth

The global industrial and commercial energy storage market is experiencing explosive growth, with demand increasing by over 250% in the past two years. Containerized energy storage solutions now account for approximately 45% of all new commercial and industrial storage deployments worldwide. North America leads with 42% market share, driven by corporate sustainability initiatives and tax incentives that reduce total project costs by 18-28%. Europe follows closely with 35% market share, where standardized industrial storage designs have cut installation timelines by 65% compared to traditional built-in-place systems. Asia-Pacific represents the fastest-growing region at 50% CAGR, with manufacturing scale reducing system prices by 20% annually. Emerging markets in Africa and Latin America are adopting industrial storage solutions for peak shaving and backup power, with typical payback periods of 2-4 years. Major commercial projects now deploy clusters of 15+ systems creating storage networks with 80+MWh capacity at costs below $270/kWh for large-scale industrial applications.

Industrial Energy System Innovations & Cost Benefits

Technological advancements are dramatically improving industrial energy storage performance while reducing costs. Next-generation battery management systems maintain optimal operating conditions with 45% less energy consumption, extending battery lifespan to 20+ years. Standardized plug-and-play designs have reduced installation costs from $85/kWh to $40/kWh since 2023. Smart integration features now allow multiple industrial systems to operate as coordinated energy networks, increasing cost savings by 30% through peak shaving and demand charge management. Safety innovations including multi-stage fire suppression and thermal runaway prevention systems have reduced insurance premiums by 35% for industrial storage projects. New modular designs enable capacity expansion through simple system additions at just $200/kWh for incremental capacity. These innovations have improved ROI significantly, with commercial and industrial projects typically achieving payback in 3-5 years depending on local electricity rates and incentive programs. Recent pricing trends show standard industrial systems (1-2MWh) starting at $330,000 and large-scale systems (3-6MWh) from $600,000, with volume discounts available for enterprise orders.