Photovoltaic Cell Generation and Recent Advancements

Jul 5, 2024 · The initial generation of photovoltaic (PV) technology employed c-Si for solar cell production. In this generation, silicon wafers are the oldest and most widely used technology,

Photovoltaic Cell Generations and Current Research

Aug 28, 2022 · We also present the latest developments in photovoltaic cell manufacturing technology, using the fourth-generation graphene-based photovoltaic cells as an example.

What Is Photovoltaic Smart Glass? | First Glass

Aug 21, 2024 · Transparent Photovoltaic Smart Glass converts ultraviolet and infrared to electricity while transmitting visible light into building interiors,

Introduction to the fourth generation solar cells

Introduction Photovoltaics is the process of converting sunlight directly into electricity using solar cells. Today it is a rapidly growing and increasingly important renewable alternative to

Photovoltaic Cell Generations | Encyclopedia MDPI

Jan 1, 2022 · Special attention has been paid to the "4th generation", where the different roles of organic and hybrid components are discussed. Finally, the author summarizes his findings and

Assessment of long term reliability of photovoltaic glass–glass modules

Apr 1, 2015 · Quantifying the reliability of photovoltaic (PV) modules is essential for consistent electrical performance and achieving long operational lifetimes.

Solar Photovoltaic Glass: Features, Type and

Jun 27, 2023 · Photovoltaic glass is a special type of glass that utilizes solar radiation to generate electricity by laminating into solar cells, and has relevant

Another Leading PV Glass Company Announces to Cut the

Aug 7, 2025 · The photovoltaic (PV) industry''s campaign against "involution" — excessive internal competition and overcapacity — has seen further concrete action. Most recently, another

AppSolEn2360091Spattelath.fm

Mar 7, 2024 · The bifacial photovoltaic technology has been briefly reviewed in the review, including the substrates used, cell texturing, antireflection coating, cell reflectors, etc. Bifacial

Multi-objective evolutionary optimization of photovoltaic glass

Nov 1, 2023 · The study applies a multi-objective evolutionary optimization algorithm for a-Si PV glass'' transmittance and window size to enhance the building''s energy performance, the case

Performance Investigation of Tempered Glass‐Based

Oct 31, 2021 · In a recent research, Suman et al. [11] have grouped the PV cell technology into four generations such as first-, second-, third-, and fourth-generation PV cells. They have

Advancements in Photovoltaic Glass Technology

Aug 19, 2025 · Photovoltaic glass integration in factoriesPhotovoltaic glass integration transforms factory roofs and walls into power-generating assets while maintaining structural integrity and

Performance Investigation of Tempered Glass-Based

Oct 31, 2021 · Abstract and Figures Solar photovoltaic (PV) converts sunlight into electricity and is an appropriate alternative to overcome the depletion of conventional fuels and global warming

What is Photovoltaic Glass (or solar pv glass)?_

Jul 23, 2025 · 1.1.7 Summary The factors determining the performance of crystalline silicon solar photovoltaic cells are various factors related to the conversion efficiency of light energy. The

Solar PV cell materials and technologies: Analyzing the

Jan 1, 2021 · In last five years, a remarkable development has been observed in the photovoltaic (PV) cell technology. To overcome the consequences on global warming due to fossil fuel

Characteristics of the fourth generation photovoltaic

What is a fourth generation photovoltaic cell? 2.4. Fourth Generation of Photovoltaic Cells Fourth-generation photovoltaic cells are also known as hybrid inorganic cellsbecause they combine

Characteristics of the fourth generation photovoltaic

Fourth-generation solar cells refer to a new generation of photovoltaic devices that aim to overcome the limitations of conventional solar cells and offer a higher efficiency,lower cost,and

Advancements and challenges in solar photovoltaic

Jan 1, 2025 · Third-generation and fourth-generation solar PV cell technologies were introduced to overcome all the drawbacks of first- and second-generation solar cells, such as technical,

Photonic microstructures for energy-generating clear glass

Aug 23, 2016 · In principle, integrating photovoltaic (PV) systems into "green" buildings can provide a significant additional source of energy generation located at any surface available

Performance Investigation of Tempered Glass‐Based

Oct 31, 2021 · In a recent research, Suman et al. [11] have grouped the PV cell technology into four generations such as first-, second-, third-, and fourth-generation PV cells.

Photovoltaic Cell Generations and Current Research

Sep 1, 2024 · We also present the latest developments in photovoltaic cell manufacturing technology, using the fourth-generation graphene-based photovoltaic cells as an example.

6 FAQs about [Fourth generation photovoltaic glass]

What is a fourth generation photovoltaic cell?

Fourth Generation of Photovoltaic Cells Fourth-generation photovoltaic cells are also known as hybrid inorganic cells because they combine the low cost and flexibility of polymer thin films, with the stability of organic nanostructures such as metal nanoparticles and metal oxides, carbon nanotubes, graphene, and their derivatives.

What is 3rd generation photovoltaic technology?

Third Generation: This generation counts photovoltaic technologies that are based on more recent chemical compounds. In addition, technologies using nanocrystalline “films,” quantum dots, dye-sensitized solar cells, solar cells based on organic polymers, etc., also belong to this generation.

What is 4gen photovoltaic solar cell?

5. Fourth-Generation Photovoltaic Solar Cells The 4GEN combines the low cost/flexibility of polymer thin-films with the good stability of nanomaterials like metallic nanoparticles, metal oxides, carbon nanotubes, graphene, and its derivatives.

What are 3rd generation solar cells?

The third generation of solar cells includes new technologies, including solar cells made of organic materials, cells made of perovskites, dye-sensitized cells, quantum dot cells, or multi-junction cells. With advances in technology, the drawbacks of previous generations have been eliminated in fourth-generation graphene-based solar cells.

What is a second generation photovoltaic cell?

Second Generation of Photovoltaic Cells The thin film photovoltaic cells based on CdTe, gallium selenide, and copper (CIGS) or amorphous silicon have been designed to be a lower-cost replacement for crystalline silicon cells.

What is the optimum PCE for 4th-generation solar cells?

An optimum PCE of 6.63% was achieved. 45 Simulation methods play a crucial role in the development of fourth-generation solar cells. Fourth-generation solar cells refer to a new generation of photovoltaic devices that aim to overcome the limitations of conventional solar cells and offer a higher efficiency, lower cost, and improved functionality.

Learn More

- Glass photovoltaic panels for power generation

- New Energy Photovoltaic Power Generation Glass Component Lamination

- Which company is professional in photovoltaic power generation glass house

- External glass curtain wall photovoltaic power generation

- Photovoltaic power generation glass applications

- Lithuania glass photovoltaic power generation

- Photovoltaic power generation glass for commercial use

- Photovoltaic power generation glass customization

- Rooftop solar glass photovoltaic power generation

Industrial & Commercial Energy Storage Market Growth

The global industrial and commercial energy storage market is experiencing explosive growth, with demand increasing by over 250% in the past two years. Containerized energy storage solutions now account for approximately 45% of all new commercial and industrial storage deployments worldwide. North America leads with 42% market share, driven by corporate sustainability initiatives and tax incentives that reduce total project costs by 18-28%. Europe follows closely with 35% market share, where standardized industrial storage designs have cut installation timelines by 65% compared to traditional built-in-place systems. Asia-Pacific represents the fastest-growing region at 50% CAGR, with manufacturing scale reducing system prices by 20% annually. Emerging markets in Africa and Latin America are adopting industrial storage solutions for peak shaving and backup power, with typical payback periods of 2-4 years. Major commercial projects now deploy clusters of 15+ systems creating storage networks with 80+MWh capacity at costs below $270/kWh for large-scale industrial applications.

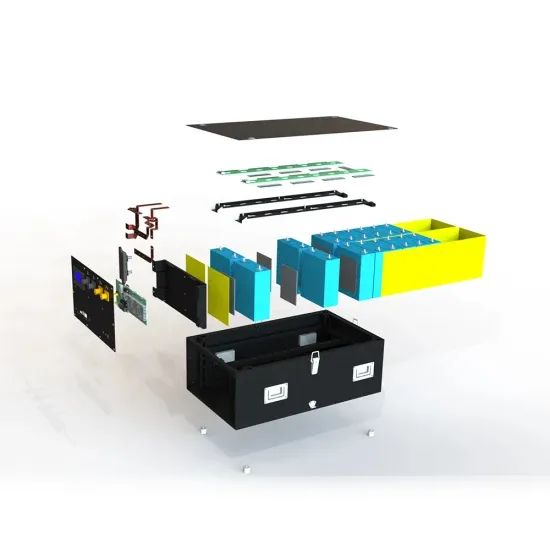

Industrial Energy System Innovations & Cost Benefits

Technological advancements are dramatically improving industrial energy storage performance while reducing costs. Next-generation battery management systems maintain optimal operating conditions with 45% less energy consumption, extending battery lifespan to 20+ years. Standardized plug-and-play designs have reduced installation costs from $85/kWh to $40/kWh since 2023. Smart integration features now allow multiple industrial systems to operate as coordinated energy networks, increasing cost savings by 30% through peak shaving and demand charge management. Safety innovations including multi-stage fire suppression and thermal runaway prevention systems have reduced insurance premiums by 35% for industrial storage projects. New modular designs enable capacity expansion through simple system additions at just $200/kWh for incremental capacity. These innovations have improved ROI significantly, with commercial and industrial projects typically achieving payback in 3-5 years depending on local electricity rates and incentive programs. Recent pricing trends show standard industrial systems (1-2MWh) starting at $330,000 and large-scale systems (3-6MWh) from $600,000, with volume discounts available for enterprise orders.