Combined hydrogen production and electricity storage using

Sep 22, 2021 · The concept offers several advantages over conventional electrolysis in terms of safety, durability, modularity, and purity. In this work, we demonstrate a vanadium-manganese

A perspective on manganese-based flow batteries

Jul 12, 2024 · Mn-based flow batteries (MFBs) are recognized as viable contenders for energy storage owing to their environmentally sustainable nature, economic feasibility, and enhanced

Hydrogen/manganese hybrid redox flow battery

Dec 11, 2018 · Hydrogen/manganese hybrid redox flow battery, Javier Rubio-Garcia, Anthony Kucernak, Dong Zhao, Danlei Li, Kieran Fahy, Vladimir Yufit, Nigel Brandon, Miguel Gomez

Titanium-Manganese Electrolyte for Redox Flow Battery

Jan 8, 2021 · For the electrolyte, we focused attention on a low-cost manganese material, for which the application to flow batteries had been abandoned because of the precipitation of

Enhancement in the performance of a vanadium-manganese redox flow

Feb 1, 2025 · Abstract This study investigates the performance of both a vanadium/manganese redox flow battery (V/Mn RFB) and an all-vanadium redox flow battery (VRFB), employing

A manganese–hydrogen battery with potential for grid-scale

Apr 30, 2018 · The manganese–hydrogen battery involves low-cost abundant materials and has the potential to be scaled up for large-scale energy storage.

Tailoring manganese coordination environment for a highly reversible

Sep 30, 2021 · Zinc-manganese flow batteries have drawn considerable attentions owing to its advantages of low cost, high energy density and environmental friendline

A self-healing electrocatalyst for manganese-based flow battery

Jun 15, 2024 · Manganese-based flow battery has attracted wide attention due to its nontoxicity, low cost, and high theoretical capacity. However, the increasing pol

Manganese-based flow battery based on the MnCl

Jun 1, 2023 · High concentration MnCl 2 electrolyte is applied in manganese-based flow batteries first time. Amino acid additives promote the reversible Mn2+ /MnO 2 reaction without Cl 2. In

Manganese-Based Redox Flow Batteries for Grid Energy

Jul 7, 2015 · The development of manganese-based anolytes as a suitable alternative to vanadium anolytes for redox flow batteries is attractive for various reasons, including a higher

Development of a Zn-Mn aqueous redox-flow battery

Nov 20, 2023 · The Zn-Mn redox pair has great potential as a next-generation redox flow battery (RFB) because of its economic strength and capability to conduct safe

High‐Areal‐Capacity Manganese‐Based Redox Flow Batteries

May 24, 2025 · Manganese (Mn)-based redox flow batteries (RFBs) have emerged as promising candidates for large-scale energy storage owing to their high redox potential (Mn 2+ /Mn 3+:

ACS Energy Letters:低成本水系硫锰液流电池

Dec 13, 2022 · 近日,来自 香港中文大学的卢怡君教授(通讯作者)以及北京化工大学的黃雅欽教授(通讯作者) 在国际知名期刊 ACS Energy Letters 上发表

Highly reversible and stable manganese (II/III)-centered

Jun 1, 2023 · Manganese (Mn) is a promising positive electrode element for aqueous redox flow batteries (ARFB); however, reversible and stable Mn species are still highly desirable. Herein,

Low-cost manganese dioxide semi-solid electrode for flow batteries

Nov 17, 2021 · Flow battery architecture is suitable for this purpose because it allows the energy components to be scaled independently from the power components. We explored the

An energy-storage solution that flows like soft

Nov 30, 2021 · An electrochemical technology called a semi-solid flow battery can be a cost-competitive form of energy storage and backup for variable sources

Rescue of dead MnO2 for stable electrolytic Zn–Mn redox-flow battery

Jul 3, 2024 · A metric of mediated kinetics and the concomitant Fe-catalysed Mn2+/MnO2 electrolysis kinetics to rescue dead MnO2 for stable Zn–Mn redox-flow battery with

Ethylenediaminetetraacetic acid enables uniform zinc

This work explores an efficient anolyte additive in improving the performance of a zinc-manganese (Zn-Mn) flow battery. Mn is appealing as a cathode redox material due to its availability,

Vanadium-Mediated High Areal Capacity Zinc–Manganese Redox Flow Battery

Apr 9, 2024 · Aqueous manganese redox flow batteries (AMRFBs) that rely on the two-electron transfer reaction of Mn2+/MnO2 have garnered significant interest because of their

6 FAQs about [Flow Battery Manganese]

What is the energy density of manganese-based flow batteries?

The energy density of manganese-based flow batteries was expected to reach 176.88 Wh L-1. Manganese-based flow batteries are attracting considerable attention due to their low cost and high safe. However, the usage of MnCl 2 electrolytes with high solubility is limited by Mn 3+ disproportionation and chlorine evolution reaction.

Which electrolyte is used in manganese-based flow batteries?

High concentration MnCl 2 electrolyte is applied in manganese-based flow batteries first time. Amino acid additives promote the reversible Mn2+ /MnO 2 reaction without Cl 2. In-depth research on the impact mechanism at the molecular level. The energy density of manganese-based flow batteries was expected to reach 176.88 Wh L-1.

Are aqueous Manganese-Based Redox Flow batteries suitable for electrochemical energy storage?

The modification strategies are discussed. The challenges and perspectives are proposed. Aqueous manganese-based redox flow batteries (MRFBs) are attracting increasing attention for electrochemical energy storage systems due to their low cost, high safety, and environmentally friendly.

Are flow batteries a good energy storage technology?

Flow batteries (FBs) are widely regarded as one of the most promising energy storage technologies owing to their advantages of high safety, environmental friendliness, and long cycle life , , .

Can high-concentration MnCl 2 electrolyte be used in zinc-manganese flow batteries?

This study provided the possibility to utilize the high-concentration MnCl 2 electrolyte (4 M) in zinc-manganese flow batteries, furthermore, the energy density of manganese-based flow batteries was expected to reach 176.88 Wh L -1.

Are aqueous Zn–Mn flow batteries suitable for large-scale energy storage?

Aqueous Zn–Mn flow batteries (Zn–Mn FBs) are a potential candidate for large-scale energy storage due to their high voltage, low cost, and environmental friendliness. However, the unsatisfactory performance due to the sluggish MnO2 reduction reaction (MnRR) kinetics leads to low discharge voltage (typically Recent Open Access Articles

Learn More

- Flow Battery Manganese

- Communication base station flow battery detector

- Address of the flow battery energy storage cabinet of the Eritrean communication base station

- N Djamena New Energy All-vanadium Liquid Flow Energy Storage Battery

- All-vanadium liquid flow battery device

- Flow battery electrode saturation

- 50mw all-vanadium liquid flow battery energy storage power station

- 1gw all-vanadium liquid flow battery energy storage

- Is flow battery a new energy source

Industrial & Commercial Energy Storage Market Growth

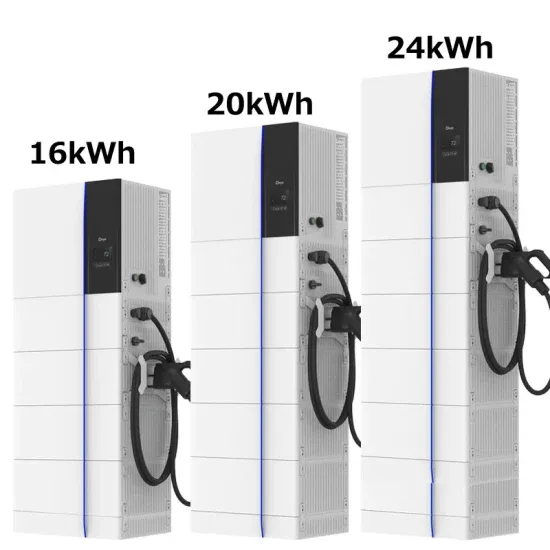

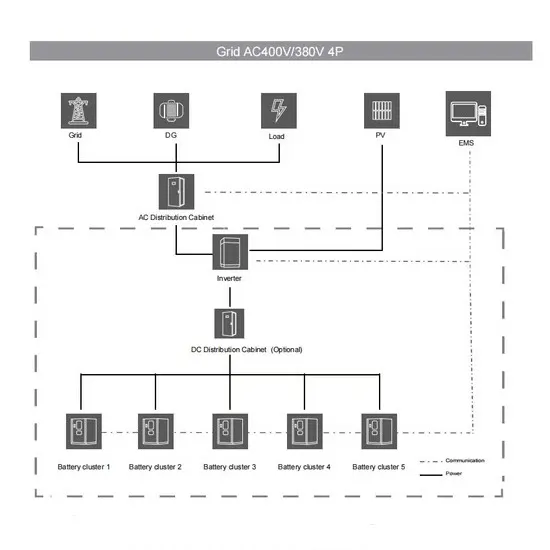

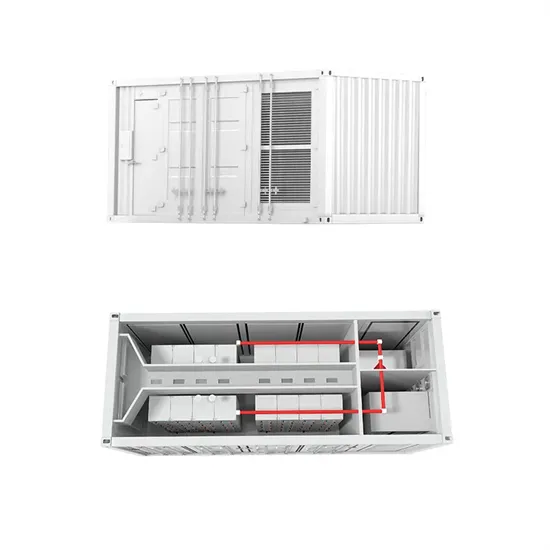

The global industrial and commercial energy storage market is experiencing explosive growth, with demand increasing by over 250% in the past two years. Containerized energy storage solutions now account for approximately 45% of all new commercial and industrial storage deployments worldwide. North America leads with 42% market share, driven by corporate sustainability initiatives and tax incentives that reduce total project costs by 18-28%. Europe follows closely with 35% market share, where standardized industrial storage designs have cut installation timelines by 65% compared to traditional built-in-place systems. Asia-Pacific represents the fastest-growing region at 50% CAGR, with manufacturing scale reducing system prices by 20% annually. Emerging markets in Africa and Latin America are adopting industrial storage solutions for peak shaving and backup power, with typical payback periods of 2-4 years. Major commercial projects now deploy clusters of 15+ systems creating storage networks with 80+MWh capacity at costs below $270/kWh for large-scale industrial applications.

Industrial Energy System Innovations & Cost Benefits

Technological advancements are dramatically improving industrial energy storage performance while reducing costs. Next-generation battery management systems maintain optimal operating conditions with 45% less energy consumption, extending battery lifespan to 20+ years. Standardized plug-and-play designs have reduced installation costs from $85/kWh to $40/kWh since 2023. Smart integration features now allow multiple industrial systems to operate as coordinated energy networks, increasing cost savings by 30% through peak shaving and demand charge management. Safety innovations including multi-stage fire suppression and thermal runaway prevention systems have reduced insurance premiums by 35% for industrial storage projects. New modular designs enable capacity expansion through simple system additions at just $200/kWh for incremental capacity. These innovations have improved ROI significantly, with commercial and industrial projects typically achieving payback in 3-5 years depending on local electricity rates and incentive programs. Recent pricing trends show standard industrial systems (1-2MWh) starting at $330,000 and large-scale systems (3-6MWh) from $600,000, with volume discounts available for enterprise orders.