Measurements and Modelling of Base Station Power

Mar 28, 2012 · Measurements show the existence of a direct relationship between base station traffic load and power consumption. According to this relationship, we develop a linear power

Power Consumption Modeling of 5G Multi-Carrier Base

Jan 23, 2023 · However, there is still a need to understand the power consumption behavior of state-of-the-art base station architectures, such as multi-carrier active antenna units (AAUs),

Environmental Engineering (EE); Measurement method

Dec 21, 2020 · Environmental Engineering (EE); Measurement method for energy efficiency of wireless access network equipment Dynamic energy performance measurement method of 5G

6.2 Base station output power – TechSpec

6.2.1 General The configured carrier power is the target maximum power for a specific carrier for the operating mode set in the BS within the limits given by the manufacturer''s declaration.

Real Time Traffic Base Station Power Consumption

Jul 10, 2016 · In this article, we investigate the effect of traffic variations on base station (BS) power consumption in Ghana. Continuous power and traffic load measurements were carried

Machine learning for base transceiver stations power failure

Dec 1, 2024 · Base Transceiver Stations (BTSs), are foundational to mobile networks but are vulnerable to power failures, disrupting service delivery and causing user inconvenience. This

Smart Power Management System for Base Stations

The intelligent base station power consumption management system installs intelligent AC and DC monitoring equipment, wireless acquisition equipment and system management platforms

Measurements and Modelling of Base Station Power Consumption under Real

Measurements show the existence of a direct relationship between base station traffic load and power consumption. According to this relationship, we develop a linear power consumption

Dynamic Power Management for 5G Small Cell Base Station

Jan 9, 2021 · 5G networks with small cell base stations are attracting significant attention, and their power consumption is a matter of significant concern. As the increase of the expectation,

Peak power shaving in hybrid power supplied 5G base

The high-power consumption and dynamic traffic demand overburden the base station and consequently reduce energy efficiency. In this paper, an energy-efficient hybrid power supply

Key Applications of Power Meters in Tower Base

Feb 14, 2025 · Power meters can measure the power factor of the base station, which reflects the efficiency of power utilization. A low power factor increases

Measurements and Modelling of Base Station Power

Aug 5, 2023 · To measure the AC energy consumption of the overall site, including the cooling system (air-conditioning) and battery supply systems, the following equipment components

DC Power Supplies for Base Station Testing | Keysight

Keysight Technologies, Inc. can help you quickly design the power supply portion of your system, leaving more time for you to concentrate on the critical issues of leading-edge base station

Filter Design of Wireless Base Station Power Supply

展开更多 The design of electromagnetic interference (EMI)filters needs to fulfill the EMI standards signing a filter is a time-consuming process for new engineers as well as for

Tower Base Station Industry Measurement Solution

Generally speaking, 5G base stations mainly include BBU+AAU. Base station room: mainly equipped with signal transceivers, monitoring devices, fire extinguishing devices, power supply

Energy Consumption Monitoring Solution for Base Station

Nov 6, 2024 · In DC side, it is necessary to monitor electrical parameters and measure energy such as base station communication device, battery and other devices working under -48V

Maintenance of communication base station power supply

This article discusses how to improve the power supply safety of the power supply system of communication base stations, reduce the failure rate of the power supply system of

Filter Design of Wireless Base Station Power Supply

The filter design procedure makes it possible to design filters quickly and easily. Finally, the proposed filter design method is proved to be effective by the EMI measurement of the

Measurements and Modelling of Base Station Power Consumption under Real

Abstract Base stations represent the main contributor to the energy consumption of a mobile cellular network. Since traffic load in mobile networks significantly varies during a working or

Comparison of Power Consumption Models for 5G Cellular Network Base

Jul 1, 2024 · Additional discussion of power models for radio access network, user equipment, and the system level as well as further remarks on base station power models can be found in

6 FAQs about [Base station power supply measurement]

Is there a direct relationship between base station traffic load and power consumption?

The real data in terms of the power consumption and traffic load have been obtained from continuous measurements performed on a fully operated base station site. Measurements show the existence of a direct relationship between base station traffic load and power consumption.

How much power does a cellular base station use?

This problem exists particularly among the mobile telephony towers in rural areas, that lack quality grid power supply. A cellular base station can use anywhere from 1 to 5 kW power per hour depending upon the number of transceivers attached to the base station, the age of cell towers, and energy needed for air conditioning.

How to design a solar-powered base station?

In order to design and implement a solar-powered base station, PVSYST simulation software has been used in various countries including India, Nigeria, Morocco, and Sweden. This software allows for estimation of the number of PV panels, batteries, inverters, and cost of production of energy considering the geographical and other design parameters.

What is the largest energy consumer in a base station?

The largest energy consumer in the BS is the power amplifier, which has a share of around 65% of the total energy consumption [ 7 ]. Of the other base station elements, significant energy consumers are: air conditioning (17.5%), digital signal processing (10%) and AC/DC conversion elements (7.5%) [ 8 ].

What type of generator does a base station use?

The air conditioning of the base station runs at 220 VAC. These base stations can be powered by two types of diesel generators. The first is the conventional type where 220 VAC is converted to 48 VDC to charge the batteries and power the communication equipment.

How do base stations affect mobile cellular network power consumption?

Base stations represent the main contributor to the energy consumption of a mobile cellular network. Since traffic load in mobile networks significantly varies during a working or weekend day, it is important to quantify the influence of these variations on the base station power consumption.

Learn More

- 5g communication micro base station power supply

- Yemen communication base station power supply manufacturer

- Uninterrupted power supply and lightning protection for Bissau communication base station

- Off-grid power supply for isolated island communication base station

- 5g communication base station super capacitor construction hybrid power supply

- Power supply and distribution for Thimphu 5G base station

- Base station power cabinet backup power supply

- Marseille 5g communication base station power supply

- How to solve the power supply problem of base station

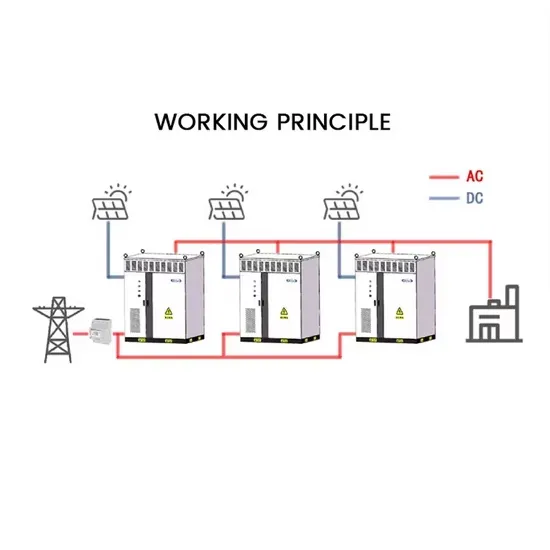

Industrial & Commercial Energy Storage Market Growth

The global industrial and commercial energy storage market is experiencing explosive growth, with demand increasing by over 250% in the past two years. Containerized energy storage solutions now account for approximately 45% of all new commercial and industrial storage deployments worldwide. North America leads with 42% market share, driven by corporate sustainability initiatives and tax incentives that reduce total project costs by 18-28%. Europe follows closely with 35% market share, where standardized industrial storage designs have cut installation timelines by 65% compared to traditional built-in-place systems. Asia-Pacific represents the fastest-growing region at 50% CAGR, with manufacturing scale reducing system prices by 20% annually. Emerging markets in Africa and Latin America are adopting industrial storage solutions for peak shaving and backup power, with typical payback periods of 2-4 years. Major commercial projects now deploy clusters of 15+ systems creating storage networks with 80+MWh capacity at costs below $270/kWh for large-scale industrial applications.

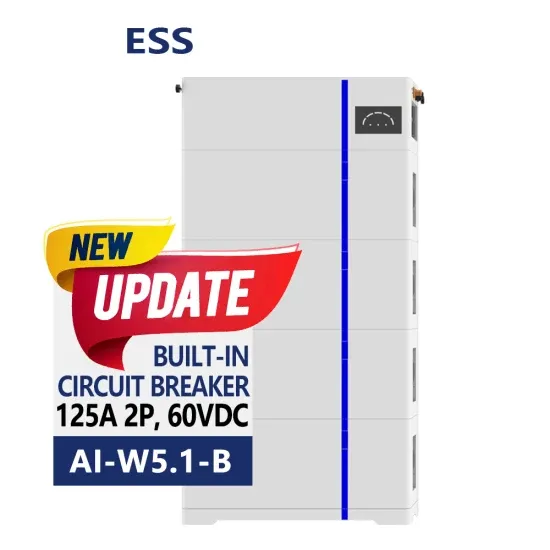

Industrial Energy System Innovations & Cost Benefits

Technological advancements are dramatically improving industrial energy storage performance while reducing costs. Next-generation battery management systems maintain optimal operating conditions with 45% less energy consumption, extending battery lifespan to 20+ years. Standardized plug-and-play designs have reduced installation costs from $85/kWh to $40/kWh since 2023. Smart integration features now allow multiple industrial systems to operate as coordinated energy networks, increasing cost savings by 30% through peak shaving and demand charge management. Safety innovations including multi-stage fire suppression and thermal runaway prevention systems have reduced insurance premiums by 35% for industrial storage projects. New modular designs enable capacity expansion through simple system additions at just $200/kWh for incremental capacity. These innovations have improved ROI significantly, with commercial and industrial projects typically achieving payback in 3-5 years depending on local electricity rates and incentive programs. Recent pricing trends show standard industrial systems (1-2MWh) starting at $330,000 and large-scale systems (3-6MWh) from $600,000, with volume discounts available for enterprise orders.