Understanding the Basics of Connecting Lithium

Oct 8, 2024 · Connecting a lithium battery to an inverter is crucial for converting the stored DC (Direct Current) energy into usable AC (Alternating Current) for

Downsize from 60v to 48 v | Endless Sphere DIY EV Forum

Oct 27, 2020 · The LVC of the 60V will be to high for the 48V unless you can change it through software, otherwise you need to find the resistor network on the pcb to change the LVC. Low

Trying to make my 60v battery usable for my 48v BBSHD,

Oct 16, 2020 · You can''t use a 60v battery for a 48v motor. The max cutoff is 60v. Thats why having a 52v (14 cell) fully charged battery would be at 58.8v. Every cell you add to the 14c

How to Effectively Use a 48V Lithium Battery

Jul 20, 2024 · To effectively use a 48V lithium battery tester, start by ensuring the tester is powered off. Connect the positive and negative leads to the battery

Is it permissible to use a 60V battery with a 48V motor?

Jan 5, 2024 · Using a 60V battery with a 48V motor is technically possible, but it comes with several considerations and potential risks. Here''s a detailed overview based on the search

Battery build question using 16s battery pack

Jul 6, 2021 · What should be the inverter/hybrid inverter I choose for this? My confusion is most inverters are either 12v or 24v or 48v. Why 60v inverters are not common? Can I use 48v

Downsize from 60v to 48 v | Endless Sphere DIY EV Forum

Oct 27, 2020 · Low Voltage Cutoff - Cuts the battery off when the battery reaches a certain voltage, for 60V it would be 49 or 50V. A fully charged 48V 13S is 54.6V using Lithium Ion

Can You Jumpstart a Lithium Ion Battery? (Well

Nov 19, 2022 · Lithium ion batteries are used in many electronic devices, from cell phones to laptops. If your car has a lithium ion battery, you may be wondering

What is the Difference Between 48V and 60V Batteries?

Dec 11, 2023 · A 60V battery generally provides higher power output, making it ideal for applications requiring more energy, while a 48V battery is often used in systems where lower

Can You Use a 72V Battery on a 60V Motor? – Booant

Apr 18, 2025 · If you''re considering upgrading your e-bike or electric vehicle with a 72V lithium battery but currently have a 60V motor system, you''re probably wondering: Is this upgrade

Can a 48V Controller Safely Handle a 60V Battery?

Aug 9, 2025 · Using a 60V battery with a 48V controller is generally not recommended due to potential risks such as overheating, damage to the controller, and safety hazards. While some

Can I use 48V charger to 60V battery?

Dec 27, 2023 · No, using a 48V charger for a 60V battery is not recommended. The voltage difference can lead to insufficient charging, potentially damaging the battery or reducing its

Can I Use a 52V Charger on a 48V Battery? A Guide

Aug 20, 2024 · Yes, you can use a 52V charger on a 48V battery, but ensure it has appropriate charging protocols to avoid overcharging risks. When it comes to charging electric batteries,

Can A 48V Inverter Connect To A 24V Battery? Compatibility

Mar 30, 2025 · However, there are options available if you want to use a 24V battery system with a 48V inverter. One option is to use multiple 24V batteries in series. Connecting two 24V

How Do You Calculate the Appropriate Inverter Size for a 48V Battery

Oct 28, 2024 · To calculate the appropriate inverter size for a 48V battery system, you need to determine the total wattage of the devices you plan to power. The formula is: Inverter Size

60v to 48v buck converter for e-bike

Jan 7, 2018 · I''m planning to use power tool batteries for my supplying voltage to a new Bafang BBS02 48v kit. Most of the ones I have are 18vdc and 20vdc. Here are the possible

Question: Can A 60V Battery Be Used On A 52V Bike

Oct 29, 2021 · Can you use a 52V battery with a 48v controller? As long as you are using a Juiced Bike with an LCD display, the 52V battery can be used. These bikes were actually initially

LiFePO4 Battery Bank in Series (48V or 60V) balancer

Dec 8, 2020 · I intend to series-connect four or five 12V Lithium batteries to make a 48V or 60V bank for my residential solar project. From my reading here and here, I understand that

Upgrading Your Electric Scooter Batteries: A Step-by-Step

Learn how to upgrade your electric scooter''s batteries with our step-by-step guide, covering the selection process, replacement, testing, and maintenance to boost performance and lifespan.

6 FAQs about [Can a 48v lithium battery be boosted to 60v using an inverter ]

Can a 60V battery be used on a 48V motor?

Using a 60V battery on a 48V motor can pose some risks and safety concerns. One of the main risks is the potential for overheating. The motor may not be able to handle the increased power, leading to excessive heat generation.

Can a 60V battery power a 48V motor?

A 48V motor is designed to handle 48 volts of electrical input. When considering using a 60V battery on a 48V motor, compatibility is an important factor.

Should you use a lithium-ion battery for a home inverter?

A lithium-ion battery for a home inverter can significantly enhance your home’s energy storage capabilities. This translates to more reliable power during outages and better management of renewable energy resources like solar panels. Lithium-ion batteries require less maintenance and have a longer lifespan compared to traditional batteries.

Should I use a 60V to 48V converter?

If you want to use all the remaining cells a "dc to dc converter 60V to 48V" would do just that. However they are hard to get for that voltage and high amps. if your controller can take 60v it will be fine just keep an eye on motor temps and avoid WOT if you find it gets hot Dana Point So. Cal It's. Best to have one big battery.

Can a solar inverter be used with a lithium battery?

Integrating a solar inverter with a lithium battery can take your renewable energy setup to the next level. This combination allows for better energy storage, improved efficiency, and greater resilience during power outages. LiFePO4 batteries are particularly well-suited for solar applications because their thermal stability and long cycle life.

How many batteries are in a 48V bank?

A 48V bank consists of four 12V batteries. For this setup, one would need 3 balancers. Should a balancer cost that much ?? I am looking for better alternatives in terms of price and compactness, preferably ones that come as a single unit for 48V banks or for 60V banks (five 12V batteries).

Learn More

- 48v lithium battery inverter recommendation

- 48v lithium battery 30a with 1000w inverter

- Base station lithium battery energy storage 15kw inverter power supply

- New 60v lithium iron phosphate battery pack

- North Africa 4-string lithium battery inverter

- Lithium battery inverter 120A

- Mauritania 4-string lithium battery inverter

- Can a 12v inverter be powered by a 14v lithium battery

- Communication between lithium battery and inverter

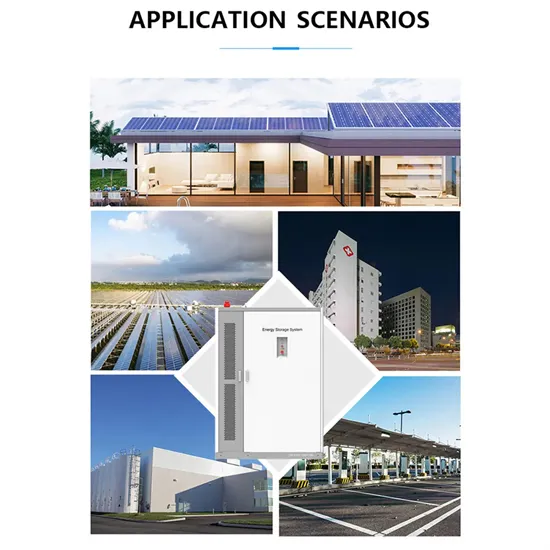

Industrial & Commercial Energy Storage Market Growth

The global industrial and commercial energy storage market is experiencing explosive growth, with demand increasing by over 250% in the past two years. Containerized energy storage solutions now account for approximately 45% of all new commercial and industrial storage deployments worldwide. North America leads with 42% market share, driven by corporate sustainability initiatives and tax incentives that reduce total project costs by 18-28%. Europe follows closely with 35% market share, where standardized industrial storage designs have cut installation timelines by 65% compared to traditional built-in-place systems. Asia-Pacific represents the fastest-growing region at 50% CAGR, with manufacturing scale reducing system prices by 20% annually. Emerging markets in Africa and Latin America are adopting industrial storage solutions for peak shaving and backup power, with typical payback periods of 2-4 years. Major commercial projects now deploy clusters of 15+ systems creating storage networks with 80+MWh capacity at costs below $270/kWh for large-scale industrial applications.

Industrial Energy System Innovations & Cost Benefits

Technological advancements are dramatically improving industrial energy storage performance while reducing costs. Next-generation battery management systems maintain optimal operating conditions with 45% less energy consumption, extending battery lifespan to 20+ years. Standardized plug-and-play designs have reduced installation costs from $85/kWh to $40/kWh since 2023. Smart integration features now allow multiple industrial systems to operate as coordinated energy networks, increasing cost savings by 30% through peak shaving and demand charge management. Safety innovations including multi-stage fire suppression and thermal runaway prevention systems have reduced insurance premiums by 35% for industrial storage projects. New modular designs enable capacity expansion through simple system additions at just $200/kWh for incremental capacity. These innovations have improved ROI significantly, with commercial and industrial projects typically achieving payback in 3-5 years depending on local electricity rates and incentive programs. Recent pricing trends show standard industrial systems (1-2MWh) starting at $330,000 and large-scale systems (3-6MWh) from $600,000, with volume discounts available for enterprise orders.