How Does an Inverter Communicate with a Battery?

Oct 31, 2024 · An inverter communicates with a battery through a series of electrical signals and protocols that manage the flow of energy. This communication ensures that the inverter can

Advanced Considerations for Connecting Lithium Batteries and Inverters

Oct 8, 2024 · For larger energy storage systems or industrial applications, connecting lithium batteries to inverters involves advanced considerations. This article addresses key factors for

Inverter to battery communication? Important or nice to have?

Sep 20, 2023 · I''d like to use an all in one 48 volt inverter/charger and a server rack battery. Is it worth spending a little extra to get both from the same manufacturer to get communication

BMS Communication Issue Between Deye Inverter and FelicitySolar Lithium

Jul 21, 2025 · I am experiencing a communication issue between my Deye inverter and a FelicitySolar lithium battery. Below are the system details: Inverter Model: Deye SUN-3.6/5/6K

Does the BMS have to be connected to the inverter?

Mar 23, 2021 · There is no communication between the BMS and the inverter, and it all works just fine. The inverter and charging source should be programmed to not exceed the safe limits of

How to Connect the Growatt SPF5000-ES To Pylontech

Aug 22, 2024 · The US5000 is a compatible lithium-ion battery with the Growatt off-grid solar inverter. The two devices can paired with the right BMS communication cable. If you have an

Practical Guide to Cross-Brand Inverter and Lithium Battery

Jul 28, 2025 · Hello everyone, I''d like to share some of practical advice on BMS communication between solar inverters and lithium batteries. Hope you find it helpful. 1. Common Challenges

Inverter to battery communication? Important or nice to have?

Sep 20, 2023 · I"m building a UPS system for my mother-in-law to power some medical equipment in the event of a grid outage. I''d like to use an all in one 48 volt inverter/charger and

Practical Guide to Cross-Brand Inverter and Lithium Battery

Jul 28, 2025 · Hello everyone, I''d like to share some of practical advice on BMS communication between solar inverters and lithium batteries. Hope you find it helpful.

Lithium battery BMS communication

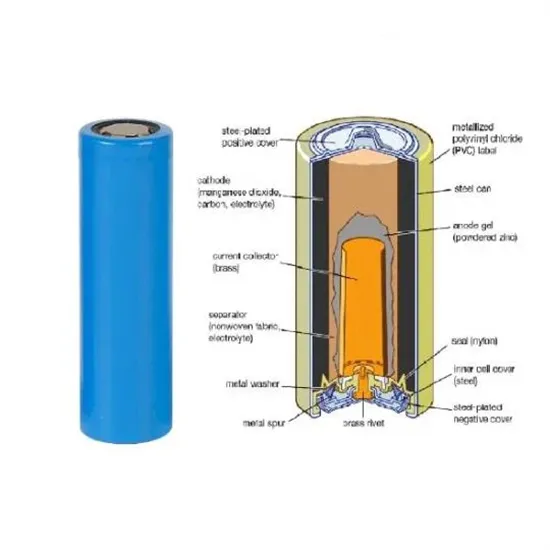

Jun 2, 2025 · In the world of renewable energy systems, the role of Battery Management Systems (BMS) has become increasingly significant, particularly when it comes to lithium battery

Lithium battery BMS communication

Jun 2, 2025 · Understanding the importance of BMS communication between inverters and lithium batteries is crucial for maximizing efficiency, safety, and longevity of energy storage systems.

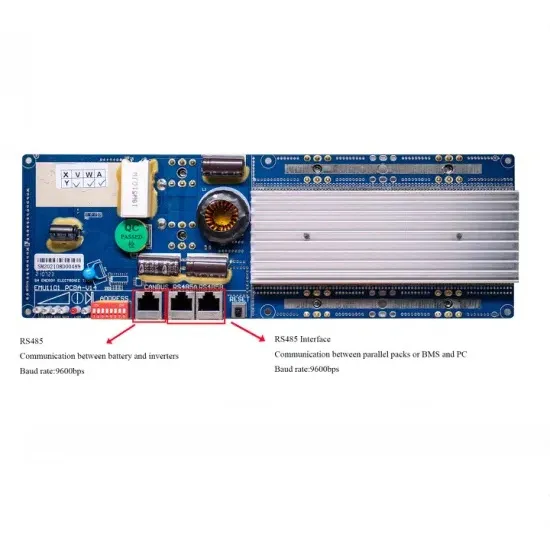

COMMUNICATION SETTINGS FOR GREENRICH BATTERY

Feb 7, 2022 · To verify that there is communication between inverter and the battery CLICK setting icon on the top right corner and click LI - BMS icon, if there is communication you

VOLTA LITHIUM BATTERY With Multiple Brands Inverter

Jul 19, 2023 · 4.1 Method 1:Communicate with factory default inverters Step 1:Select the cables used by the inverter by the label on the communication cables sert the RJ45 connector of

Does Lithium Battery Need to Communicate with Inverter?

Mar 7, 2025 · Different brands or models of lithium batteries may use different communication protocols or communication interfaces, so the inverter needs to have corresponding

6 FAQs about [Communication between lithium battery and inverter]

Can a lithium battery communicate with an inverter?

Most Lithium batteries on the market cannot communicate with inverters or only offer limited communication, which we call “Open-Loop”. This does not allow the battery management system (BMS) of the battery to send and receive data or “talk” with inverters.

How do you connect a lithium battery to an inverter?

BMS Communication Link: Most lithium batteries come with a built-in BMS that can communicate with the inverter. Ensure that this link is properly established by connecting the BMS output to the corresponding input on the inverter.

Are hybrid inverters compatible with lithium batteries?

Compatibility is the first and foremost consideration when setting up communication between a lithium battery and a hybrid inverter. Not all inverters are compatible with all lithium batteries. Therefore, it is crucial to ensure that the inverter you choose is designed to work with the specific type of lithium battery you plan to use.

What kind of communication do most lithium batteries have?

Most Lithium batteries on the market have no communication at all, or they can only offer a very limited communication, which we call “Open-Loop”. This does not allow the battery management system (BMS) of the battery to send and receive data or “talk” with inverters.

How does a battery-inverter system work?

In a power system with closed-loop communication, the inverter, solar charge controllers, and other components do not control the battery. Instead, the battery informs the decisions made by everything else in the system. The performance of any battery-inverter combination depends on how effectively the battery can fulfill this role.

Why are some batteries not able to communicate with a lithium battery?

This is a major reason why some manufacturers have yet to transition from lead acid to lithium, despite the benefits of lithium batteries, such as lower weight and higher energy density. There are lithium battery brands that take pride in not having any communication capabilities at all.

Learn More

- Bishkek communication base station lithium battery energy storage

- Saudi Arabia lithium battery inverter use

- Beirut Communication Base Station Lithium Ion Battery Room

- 3KW lithium battery inverter

- Pure sine wave lithium battery inverter

- How to pair the inverter with lithium battery

- Benin wireless communication base station lithium ion battery

- Lithium battery inverter brand

- Lithium battery inverter custom manufacturer

Industrial & Commercial Energy Storage Market Growth

The global industrial and commercial energy storage market is experiencing explosive growth, with demand increasing by over 250% in the past two years. Containerized energy storage solutions now account for approximately 45% of all new commercial and industrial storage deployments worldwide. North America leads with 42% market share, driven by corporate sustainability initiatives and tax incentives that reduce total project costs by 18-28%. Europe follows closely with 35% market share, where standardized industrial storage designs have cut installation timelines by 65% compared to traditional built-in-place systems. Asia-Pacific represents the fastest-growing region at 50% CAGR, with manufacturing scale reducing system prices by 20% annually. Emerging markets in Africa and Latin America are adopting industrial storage solutions for peak shaving and backup power, with typical payback periods of 2-4 years. Major commercial projects now deploy clusters of 15+ systems creating storage networks with 80+MWh capacity at costs below $270/kWh for large-scale industrial applications.

Industrial Energy System Innovations & Cost Benefits

Technological advancements are dramatically improving industrial energy storage performance while reducing costs. Next-generation battery management systems maintain optimal operating conditions with 45% less energy consumption, extending battery lifespan to 20+ years. Standardized plug-and-play designs have reduced installation costs from $85/kWh to $40/kWh since 2023. Smart integration features now allow multiple industrial systems to operate as coordinated energy networks, increasing cost savings by 30% through peak shaving and demand charge management. Safety innovations including multi-stage fire suppression and thermal runaway prevention systems have reduced insurance premiums by 35% for industrial storage projects. New modular designs enable capacity expansion through simple system additions at just $200/kWh for incremental capacity. These innovations have improved ROI significantly, with commercial and industrial projects typically achieving payback in 3-5 years depending on local electricity rates and incentive programs. Recent pricing trends show standard industrial systems (1-2MWh) starting at $330,000 and large-scale systems (3-6MWh) from $600,000, with volume discounts available for enterprise orders.