Understanding the Basics of Connecting Lithium

Oct 8, 2024 · Connecting a lithium battery to an inverter is crucial for converting the stored DC (Direct Current) energy into usable AC (Alternating Current) for

Battery for 3000W 12v inverter

Mar 13, 2023 · Last thing I will add is a 3000 watt inverter uses 24 watts an hour for idle draw per hour or 600 watt hours, or half a 100 ah battery. To me, you have a good plan minus the 12 volt.

3000wh 48V 60ah Lithium Battery Rechargeable with UPS

Jun 13, 2023 · 3000wh 48V 60ah Lithium Battery Rechargeable with UPS Function 220V Inverter for Camping Outlet, Find Details and Price about Lithium Battery Lithium Battery

Calculating the Right Battery Size for Your 3000W Inverter: A

When it comes to setting up an off-grid power system or a backup power solution, one of the most critical components to consider is the battery bank. The size and capacity of your battery bank

Charging Battery While Connected To Inverter

Mar 3, 2023 · Can I charge a battery while it''s connected to an inverter? in short, the answer is Yes, you can charge a battery while using an inverter. but make

Battery size for MultiPlus II 12/3000/120-32

Aug 8, 2022 · This means with the 3,000 watt Multiplus II max performance of 3,000watts, the recommended max battery draw is a good 600 Watts below inverter capacity. If we were using

VOLTWORKS 3000W Pure Sine Wave Power Inverter 3000 Watt

Jul 26, 2019 · Buy VOLTWORKS 3000W Pure Sine Wave Power Inverter 3000 Watt 12V DC to 110V 120V AC ETL Listed UL458 Compatible with Starlink & Lithium Battery for Off-Grid Solar Car RV Truck Boat with 30FT Wired Remote: Power Inverters - Amazon FREE DELIVERY

What Are the Best Lithium Batteries for 3000-Watt Power Inverters?

Mar 11, 2025 · For a 48V system, one 48V100Ah LiFePO4 battery can power a 3000W inverter for about 1.6 hours at full load. Extending runtime requires adding parallel batteries to increase

48V 60AH lithium ion battery BMS li ion battery for 3000w

48V 60AH lithium ion battery BMS li ion battery for 3000w AGV scooter bike Tricycle inverter golf cart boat + 10A Charger Color: with 50A BMS 2000W with 80A BMS 3200W with 50A BMS

How Many Batteries Do You Need for a 3000 Watt Inverter?

Feb 25, 2025 · Determining the number of batteries required for a 3000 watt inverter involves several key considerations, including energy consumption, battery voltage, and desired runtime.

Will a 100Ah Battery Run a 3000W Inverter?

When operating at full capacity, a 3000W inverter consumes approximately 3000 watt-hours (Wh) of energy per hour, so managing power consumption and monitoring battery levels is crucial

3000w inverter Prices | Compare Prices & Shop Online

4 days ago · Weight : 0Weight : YesThe Ryobi RG-3000I 3000W Inverter Generator is an excellent choice for those who need a reliable source of power. This powerful generator

Lithium (LiFePO4) Battery Runtime Calculator

Mar 3, 2023 · Use our lithium battery runtime (life) calculator to find out how long your lithium (LiFePO4, Lipo, Lithium Iron Phosphate) battery will last running a

How Many Batteries For A 3000-Watt Inverter?

Feb 16, 2023 · A 3000-watt inverter is an electrical device that converts DC (direct current) power from a battery into AC (alternating current) power that can be

Configure Batteries for 3000W Inverter Power

Jun 19, 2024 · Configuring batteries for a 3000W inverter involves understanding power requirements, calculating necessary capacity, and selecting appropriate

6 FAQs about [48v60ah lithium battery connected to inverter 3000 watts]

What is a 48V 3000W power inverter?

Overall, a 48V 3000W power inverter provides a versatile and efficient solution for converting DC power into usable AC power in a variety of applications. Note: Refrigerator or similar to the refrigerator load equipment, need to choose 10 times more power inverter.

How many batteries do I need for a 3000 watt inverter?

So to get more capacity you can hook up multiple batteries to an inverter. To work out how many batteries you need for a 3000 watt inverter you just need to know how many amps your inverter uses each hour. (The same equation as above: running Watts ÷ Volts = Inverter Amps). Then you just multiply your inverter amps by the runtime you need.

How long can a 3000 watt inverter run?

Let’s say you have a 300Ah battery. 300 ÷ 250 = 1.2 hours. Drawing 3000 watts from a 300Ah battery will run for a maximum of 1.2 hours. If you reduce your power draw to 2000 watts, you would increase your runtime to nearly 2 hours! Remember, a 3000W inverter won’t always draw maximum power, it depends what appliances you are running.

Which battery bank is best for a 24V 3000W inverter?

To keep your batteries operating safely and reliably, it is always recommended to go for a somewhat larger battery bank- generally, for lead-acid batteries 6 x 100Ah 24V battery Or 12 x 100Ah 12V battery is the smallest battery bank recommended for the 24V 3000W inverter.

How many amps does a 12V 3000 watt inverter draw?

For a 12V 3000 watt inverter: 3000 watts / 12 volts = 250 amps. This means that when fully loaded (3000 watts), it will draw 250 amps from the batteries (ignoring things like efficiency). So, you would need batteries with a capacity to meet a discharge rate (C-Rate) that allows the inverter to draw 250 amps safely.

How many amps does a 3000 watt inverter use?

Since the recommended C-Rate for lithium batteries is 0.5C, you would need at least batteries with a capacity of (250A ÷ 0.5 =) 500Ah 12V or 6 kWh. For a 3000 watt inverter at 24 volts: 3000 watts / 24 volts = 125 amps. You would need batteries with a capacity that allows the inverter to draw 125 amps safely.

Learn More

- How many watts of inverter do I need for a 20A lithium battery

- Lithium phosphate battery connected to inverter

- RV lithium battery connected to inverter

- Can the 12v lithium battery in Antananarivo be connected to an inverter

- Can a 16v lithium battery be connected to a 12v inverter

- Estonia custom made lithium battery inverter

- 100a lithium battery with 2000w inverter

- Lithium battery inverter integrated

- How big a lithium battery can be used with an inverter

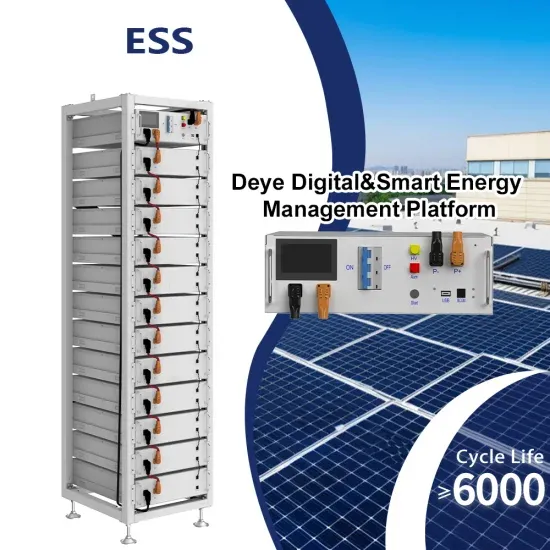

Industrial & Commercial Energy Storage Market Growth

The global industrial and commercial energy storage market is experiencing explosive growth, with demand increasing by over 250% in the past two years. Containerized energy storage solutions now account for approximately 45% of all new commercial and industrial storage deployments worldwide. North America leads with 42% market share, driven by corporate sustainability initiatives and tax incentives that reduce total project costs by 18-28%. Europe follows closely with 35% market share, where standardized industrial storage designs have cut installation timelines by 65% compared to traditional built-in-place systems. Asia-Pacific represents the fastest-growing region at 50% CAGR, with manufacturing scale reducing system prices by 20% annually. Emerging markets in Africa and Latin America are adopting industrial storage solutions for peak shaving and backup power, with typical payback periods of 2-4 years. Major commercial projects now deploy clusters of 15+ systems creating storage networks with 80+MWh capacity at costs below $270/kWh for large-scale industrial applications.

Industrial Energy System Innovations & Cost Benefits

Technological advancements are dramatically improving industrial energy storage performance while reducing costs. Next-generation battery management systems maintain optimal operating conditions with 45% less energy consumption, extending battery lifespan to 20+ years. Standardized plug-and-play designs have reduced installation costs from $85/kWh to $40/kWh since 2023. Smart integration features now allow multiple industrial systems to operate as coordinated energy networks, increasing cost savings by 30% through peak shaving and demand charge management. Safety innovations including multi-stage fire suppression and thermal runaway prevention systems have reduced insurance premiums by 35% for industrial storage projects. New modular designs enable capacity expansion through simple system additions at just $200/kWh for incremental capacity. These innovations have improved ROI significantly, with commercial and industrial projects typically achieving payback in 3-5 years depending on local electricity rates and incentive programs. Recent pricing trends show standard industrial systems (1-2MWh) starting at $330,000 and large-scale systems (3-6MWh) from $600,000, with volume discounts available for enterprise orders.