Understanding Battery Capacity and Inverter Compatibility

Aug 20, 2024 · This calculation assumes ideal conditions with no inefficiencies. In reality, factors such as inverter efficiency and battery discharge characteristics might affect the actual run

Lithium battery and inverter troubleshooting

Aug 28, 2023 · The Redodo 200ah,100a BMS battery I had in question did seem to have a failing BMS, or it was incompatible with my 2000w Renogy inverter. No matter whether the inverter

Will a 100Ah Lithium Battery Run a 2000W Inverter?

Apr 11, 2025 · A 100Ah lithium battery can technically power a 2000W inverter but only for short durations (≈30 minutes at full load). Key factors include battery voltage (12V/24V), inverter

Can a 12V 100Ah Lithium Ion Battery Power a 2000W Inverter?

Jul 22, 2025 · When considering if a 12V 100Ah lithium ion battery can power a 2000W inverter, you must evaluate several factors. These include the battery''s capacity and the inverter''s

Dual 100A LiFeP04 batteries with 2000 watt inverter.

Feb 7, 2022 · Dual 100A LiFeP04 batteries with 2000 watt inverter. I have a travel trailer. I was going to purchase 2 100aH batteries (each has a 100a BMS), but want to occasionally use a

Can a 100Ah Battery Power a 2000W Inverter? Key Insights

A 100Ah battery can technically run a 2000W inverter but only for 36–50 minutes at full load, assuming a 12V system and 85% inverter efficiency. Real-world runtime depends on battery

How Long Will a 100Ah Battery Last with a 2000W Inverter?

Apr 20, 2025 · Understanding how long a 100Ah battery will last when paired with a 2000W inverter is crucial for anyone relying on portable power solutions. The run time depends on

Outback 2000W Inverter / 100A Charger

Chargex manufactures high-performance lithium ion batteries for solar energy, RVs, marine vessels, electric vehicles, and industrial applications. Long-lasting, lightweight, and reliable

What Size Inverter Can I Run Off a 100Ah Lithium Battery?

Oct 31, 2024 · When using a 100Ah lithium battery, the size of the inverter you can run typically depends on the battery''s capacity and the power requirements of your devices. Generally, you

Why You Should Consider Running a 2000W Inverter with a 100Ah Battery

Apr 26, 2025 · What factors affect the performance of a 2000W inverter with a 100Ah battery? Several factors influence how well this setup performs: Inverter Efficiency: Most inverters

Will a 100Ah lithium battery run a 2000W inverter?

Oct 15, 2024 · Yes, a 100Ah lithium battery can run a 2000W inverter, but several factors must be considered to ensure optimal performance. The capacity of the battery, inverter efficiency, and

What Size Battery Do I Need to Run a 2000W Inverter?

To run a 2000W inverter, you need to consider the appropriate battery size to ensure optimal performance and efficiency. Generally, for a 2000W inverter, a battery capacity of at least

How Many 100Ah Batteries Do I Need with a 2000-Watt Inverter?

Dec 19, 2023 · To power a 2000-watt inverter, you typically need two 100Ah batteries connected in parallel. This configuration allows for sufficient energy storage and ensures that the inverter

100AH Battery for 2000 Watt Inverter?

Nov 19, 2019 · Most budget LiFePO4 100ah batteries are only equipped with BMS''s rated for a 100 amp sustained discharge, which is inadequate to power a 2000 watt inverter especially at

Will a 100Ah Battery Run a 2000W Inverter?

Dec 22, 2023 · A 100Ah battery can run a 2000W inverter, but the runtime will depend on several factors, including the inverter''s efficiency and the load connected to it. Generally, a 100Ah

Will a 100Ah lithium battery run a 2000W inverter?

May 22, 2025 · A 100Ah lithium battery can technically run a 2000W inverter but with significant limitations. At 12V, its usable energy (after 80% depth of discharge and 90% inverter

How Can a 100Ah Lithium Battery Support a 2000W Inverter?

Apr 21, 2025 · Using a 100Ah lithium battery with a 2000W inverter is theoretically possible, but practical limitations exist regarding runtime and efficiency. Understanding these factors is

What size inverter do you need for a 100ah

Oct 17, 2022 · What size inverter for a 100Ah battery? For appliances that use a relatively low amount of power, such as laptops, lights, TVs, and small fridges,

Can I use a 2000W inverter with a 100Ah battery?

May 3, 2025 · What factors determine inverter-battery compatibility? Voltage alignment and current limits are critical. A 12V 2000W inverter requires 167A, but most 100Ah lead-acid

6 FAQs about [100a lithium battery with 2000w inverter]

Can a 100Ah battery power a 2000W inverter?

A 100Ah battery is not enough to run a 2000W inverter. A battery with a higher voltage and capacity, such as a 100Ah-150Ah lithium battery, is required to operate a 1000W inverter or more.

How to choose batteries for a 2000 watt inverter?

Choosing batteries for your 2000-watt inverter requires careful consideration. Let’s focus on key factors: Significance: Determines how long appliances can be powered before recharge. Recommendation: Opt for a minimum capacity of 100Ah for a 2000-watt inverter. Options: Consider lead-acid, lithium-ion, gel-cell, or AGM batteries.

How many Watts Does a 100A LiFeP04 inverter need?

Dual 100A LiFeP04 batteries with 2000 watt inverter. I have a travel trailer. I was going to purchase 2 100aH batteries (each has a 100a BMS), but want to occasionally use a microwave with an inverter. The inverter would need to be 1500-2000 watts to power the Microwave (13 amps at 110V). This would mean drawing over 100 amps at 12 volts.

How do I choose the right 100Ah battery?

Considerations: Factor in peak power requirements, daily energy consumption, and desired backup time. Result: Determine the right number of 100Ah batteries for your system without overloading. Importance: Distribute the load evenly to prevent premature failure or degradation of individual cells.

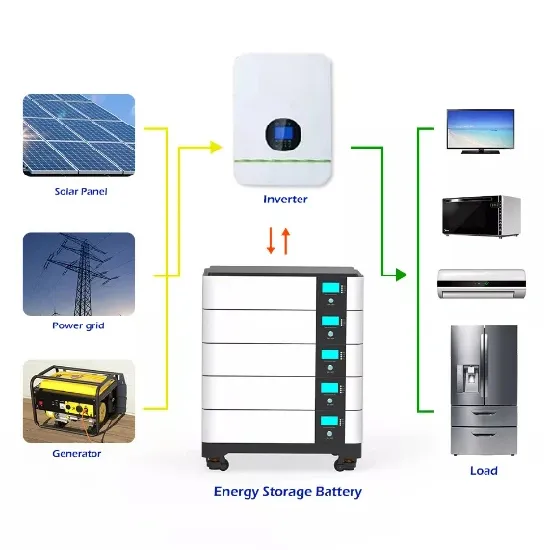

What are the different types of batteries & inverters?

Lithium Batteries: These use lithium-ion technology for efficient energy storage, offering high density and longer lifespan, ideal for various applications like RVs and solar systems due to their lightweight and efficiency. Inverters: These devices convert battery DC into household appliance-friendly AC power.

How to choose a battery inverter?

Role: Store energy for the inverter system. Consideration: Choose based on capacity (ampere-hour rating) to match usage needs. Importance: Ensure the inverter matches battery voltage and output requirements. Tip: Different batteries (e.g., lead-acid vs. lithium-ion) have varied advantages and drawbacks.

Learn More

- 100a lithium battery inverter

- 100A 12V lithium battery pack

- Male Base Station Lithium Battery Energy Storage 50kw Inverter

- Can Taipei lithium battery inverter be used

- Is lithium battery plus inverter a mobile power supply

- What size inverter is suitable for lithium battery

- Customized lithium battery inverter price

- Smallest inverter with lithium battery

- 20ah lithium battery with inverter

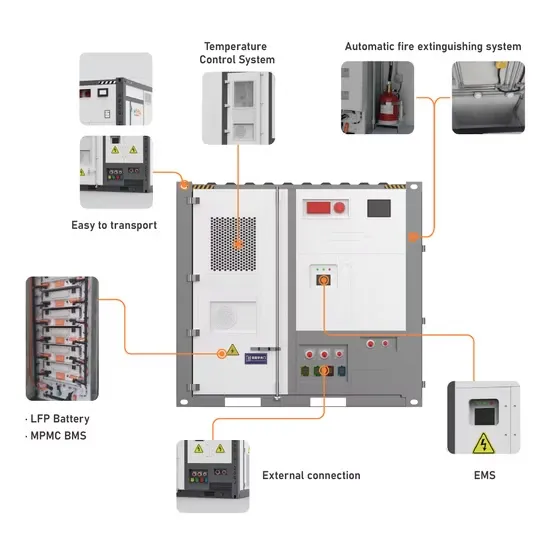

Industrial & Commercial Energy Storage Market Growth

The global industrial and commercial energy storage market is experiencing explosive growth, with demand increasing by over 250% in the past two years. Containerized energy storage solutions now account for approximately 45% of all new commercial and industrial storage deployments worldwide. North America leads with 42% market share, driven by corporate sustainability initiatives and tax incentives that reduce total project costs by 18-28%. Europe follows closely with 35% market share, where standardized industrial storage designs have cut installation timelines by 65% compared to traditional built-in-place systems. Asia-Pacific represents the fastest-growing region at 50% CAGR, with manufacturing scale reducing system prices by 20% annually. Emerging markets in Africa and Latin America are adopting industrial storage solutions for peak shaving and backup power, with typical payback periods of 2-4 years. Major commercial projects now deploy clusters of 15+ systems creating storage networks with 80+MWh capacity at costs below $270/kWh for large-scale industrial applications.

Industrial Energy System Innovations & Cost Benefits

Technological advancements are dramatically improving industrial energy storage performance while reducing costs. Next-generation battery management systems maintain optimal operating conditions with 45% less energy consumption, extending battery lifespan to 20+ years. Standardized plug-and-play designs have reduced installation costs from $85/kWh to $40/kWh since 2023. Smart integration features now allow multiple industrial systems to operate as coordinated energy networks, increasing cost savings by 30% through peak shaving and demand charge management. Safety innovations including multi-stage fire suppression and thermal runaway prevention systems have reduced insurance premiums by 35% for industrial storage projects. New modular designs enable capacity expansion through simple system additions at just $200/kWh for incremental capacity. These innovations have improved ROI significantly, with commercial and industrial projects typically achieving payback in 3-5 years depending on local electricity rates and incentive programs. Recent pricing trends show standard industrial systems (1-2MWh) starting at $330,000 and large-scale systems (3-6MWh) from $600,000, with volume discounts available for enterprise orders.