Multi-objective topology optimization design of liquid-based cooling

Feb 1, 2025 · Developing energy storage system based on lithium-ion batteries has become a promising route to mitigate the intermittency of renewable energies and improve their

Liquid Cooling: Powering the Future of Battery Energy Storage

Apr 2, 2025 · Liquid cooling is now emerging as the preferred solution, offering better heat dissipation, efficiency, and reliability. Air cooling works by circulating air around battery cells,

A Review on Thermal Management of Li-ion

Dec 7, 2024 · Li-ion battery is an essential component and energy storage unit for the evolution of electric vehicles and energy storage technology in the future.

Comparative Analysis of Lithium-Ion Batteries and Liquid Air Energy

May 28, 2025 · The global energy landscape is undergoing a paradigm shift driven by the increasing penetration of renewable energy sources into the electrical power grid. However,

Channel structure design and optimization for immersion cooling

Jan 30, 2024 · The phenomenon of heat accumulation during the discharge process of lithium-ion batteries (LIBs) significantly impacts their performance, lifespan, and safety. A well-designed

Lithium Battery Thermal Management Based on Lightweight

Jan 19, 2024 · Abstract. This study proposes a stepped-channel liquid-cooled battery thermal management system based on lightweight. The impact of channel width, cell-to-cell lateral

A critical review of thermal management systems for lithium-ion batteries

Aug 19, 2025 · Akbarzadeh M, Kalogiannis T, Jaguemont J et al (2021) A comparative study between air cooling and liquid cooling thermal management systems for a high-energy lithium

An efficient immersion cooling of lithium-ion battery for

Nov 25, 2024 · In the present numerical study, a detailed investigation of direct liquid cooling or immersion cooling using splitter hole arrangements are considered. The characteristics of Li

Research on Optimization of Thermal Management System for Liquid

Apr 19, 2025 · This paper focuses on the optimization of the cooling performance of liquid-cooling systems for large-capacity energy storage battery modules. Combining simulation analysis

Modeling and analysis of liquid-cooling thermal

Sep 1, 2023 · Modeling and analysis of liquid-cooling thermal management of an in-house developed 100 kW/500 kWh energy storage container consisting of lithium-ion batteries retired

Liquid Cooling: Powering the Future of Battery Energy Storage

Apr 2, 2025 · The liquid cooling market for stationary battery energy storage system is projected to reach $24.51 billion by 2033, growing at a CAGR of 21.55%.

An optimal design of battery thermal management system

Oct 10, 2024 · A thermal management system utilizing liquid immersion cooling was developed, providing both cooling and heating functionalities. The system was tested on a 48 V 26 Ah

6 FAQs about [Lithium battery liquid cooling energy storage]

What is liquid cooling in lithium ion battery?

With the increasing application of the lithium-ion battery, higher requirements are put forward for battery thermal management systems. Compared with other cooling methods, liquid cooling is an efficient cooling method, which can control the maximum temperature and maximum temperature difference of the battery within an acceptable range.

Does lithium-ion battery thermal management use liquid-cooled BTMS?

Liquid cooling, due to its high thermal conductivity, is widely used in battery thermal management systems. This paper first introduces thermal management of lithium-ion batteries and liquid-cooled BTMS.

How to cool a lithium ion battery?

Non-direct contact liquid cooling is also an important way for battery cooling. According to Sheng et al.'s findings , utilizing a cellular liquid cooling jacket for cylindrical lithium-ion battery cooling maintain keep their temperature below 39 °C during discharge at a rate of 2.5C, surpassing the results obtained in this study. Fig. 8.

Is there a thermal management system for lithium-ion batteries?

Zhao et al. proposed a novel thermal management system for lithium-ion battery modules that combines direct liquid-cooling with forced air-cooling, utilizing transformer oil as the liquid cooling medium. However, the complex nature of this system results in a low volumetric energy density for this battery pack.

Are lithium-ion batteries temperature sensitive?

However, lithium-ion batteries are temperature-sensitive, and a battery thermal management system (BTMS) is an essential component of commercial lithium-ion battery energy storage systems. Liquid cooling, due to its high thermal conductivity, is widely used in battery thermal management systems.

Can liquid cooling improve battery thermal management?

They found that the thermal management achieved through single-phase liquid cooling method can effectively and safely maintain desired temperatures within battery cells and modules. G. Satyanarayana et al. studied the immersion cooling performance of lithium-ion batteries using mineral oil and therminol oil.

Learn More

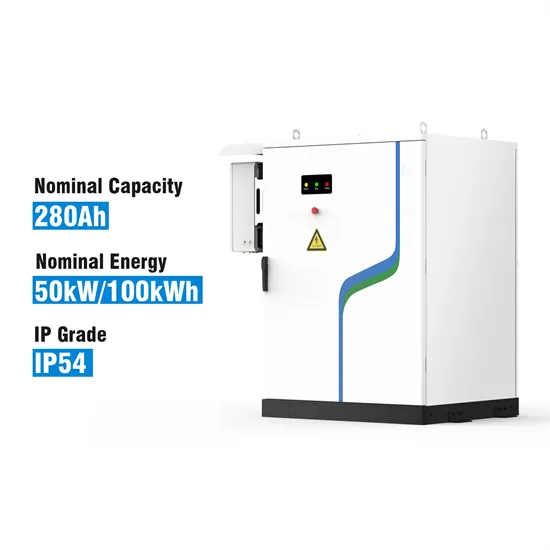

- Energy storage liquid cooling battery storage

- Liquid Cooling Energy Storage Battery Cabinet

- Does sodium-ion battery energy storage require liquid cooling

- Yemen Liquid Cooling Energy Storage Battery Cabinet Integration System

- What are the liquid cooling components of liquid-cooled energy storage battery pack

- How to charge the battery cabinet liquid cooling energy storage solar panels

- Mauritania 48v energy storage lithium battery

- Lithium battery energy storage direction

- Iranian all-vanadium liquid flow energy storage battery

Industrial & Commercial Energy Storage Market Growth

The global industrial and commercial energy storage market is experiencing explosive growth, with demand increasing by over 250% in the past two years. Containerized energy storage solutions now account for approximately 45% of all new commercial and industrial storage deployments worldwide. North America leads with 42% market share, driven by corporate sustainability initiatives and tax incentives that reduce total project costs by 18-28%. Europe follows closely with 35% market share, where standardized industrial storage designs have cut installation timelines by 65% compared to traditional built-in-place systems. Asia-Pacific represents the fastest-growing region at 50% CAGR, with manufacturing scale reducing system prices by 20% annually. Emerging markets in Africa and Latin America are adopting industrial storage solutions for peak shaving and backup power, with typical payback periods of 2-4 years. Major commercial projects now deploy clusters of 15+ systems creating storage networks with 80+MWh capacity at costs below $270/kWh for large-scale industrial applications.

Industrial Energy System Innovations & Cost Benefits

Technological advancements are dramatically improving industrial energy storage performance while reducing costs. Next-generation battery management systems maintain optimal operating conditions with 45% less energy consumption, extending battery lifespan to 20+ years. Standardized plug-and-play designs have reduced installation costs from $85/kWh to $40/kWh since 2023. Smart integration features now allow multiple industrial systems to operate as coordinated energy networks, increasing cost savings by 30% through peak shaving and demand charge management. Safety innovations including multi-stage fire suppression and thermal runaway prevention systems have reduced insurance premiums by 35% for industrial storage projects. New modular designs enable capacity expansion through simple system additions at just $200/kWh for incremental capacity. These innovations have improved ROI significantly, with commercial and industrial projects typically achieving payback in 3-5 years depending on local electricity rates and incentive programs. Recent pricing trends show standard industrial systems (1-2MWh) starting at $330,000 and large-scale systems (3-6MWh) from $600,000, with volume discounts available for enterprise orders.