Compressed-Air Energy Storage Systems | SpringerLink

Dec 17, 2019 · In this case, the fluid is released from its high-pressure storage and into a rotational energy extraction machine (an air turbine) that would convert the kinetic energy of

Development and comprehensive thermo-economic analysis

Sep 15, 2024 · The analysis indicates that increasing turbine inlet pressure and temperature significantly improves system performance. While increasing flash pressure and the

Seasonal storage of solar thermal energy through

CAES is an energy storage technology based on gas turbine technology, which uses electricity to compress air and stores the high-pressure air in storage reservoir by means of underground

Compressed air energy storage in integrated energy systems

Oct 1, 2022 · Among all energy storage systems, the compressed air energy storage (CAES) as mechanical energy storage has shown its unique eligibility in terms of clean storage medium,

A comparative study between air cooling and liquid cooling

Nov 5, 2021 · The parasitic power consumption of the battery thermal management systems is a crucial factor that affects the specific energy of the battery pack. In this paper, a comparative

Advanced Compressed Air Energy Storage Systems:

Mar 1, 2024 · Compressed air energy storage (CAES) is an effective solution for balancing this mismatch and therefore is suitable for use in future electrical systems to achieve a high

A novel multi-generation liquid air energy storage system

Aug 1, 2025 · Integrating air separation units (ASUs) with a liquid air energy storage (LAES) system offers enhanced revenue potential for LAES and a reduced paybac

SPECIFICATIONS-Air Cooling Energy Storage System.cdr

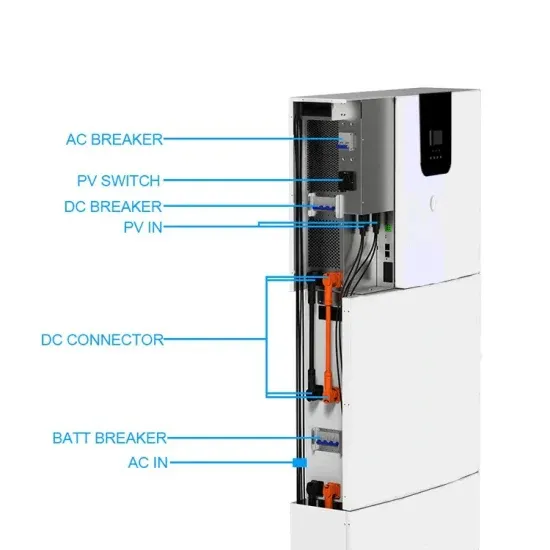

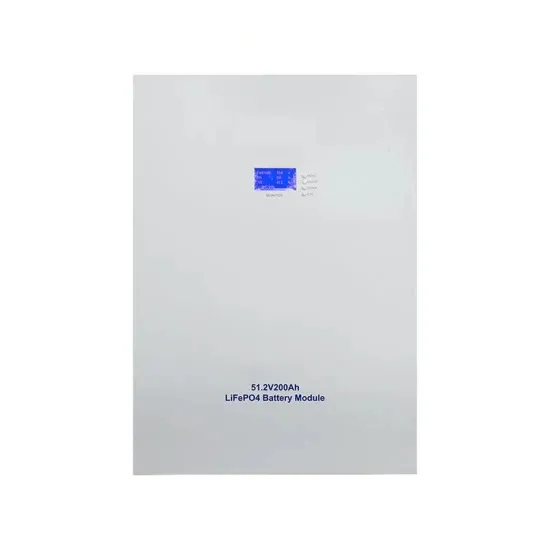

Jan 26, 2024 · Product Introduction The 115kWh air cooling energy storage system cabinet adopts an "All-In-One" design concept, with ultra-high integration that combines energy storage

Recent advances in hybrid compressed air energy storage systems

Mar 1, 2025 · The unpredictable nature of renewable energy creates uncertainty and imbalances in energy systems. Incorporating energy storage systems into energy an

Design and performance analysis of a novel liquid air energy storage

Jan 15, 2025 · In the context of the rapid transition of the global energy system to a clean and low-carbon renewable energy framework, the technology of liquid air storage is a competitive

SPECIFICATIONS-Air Cooling Energy Storage System.cdr

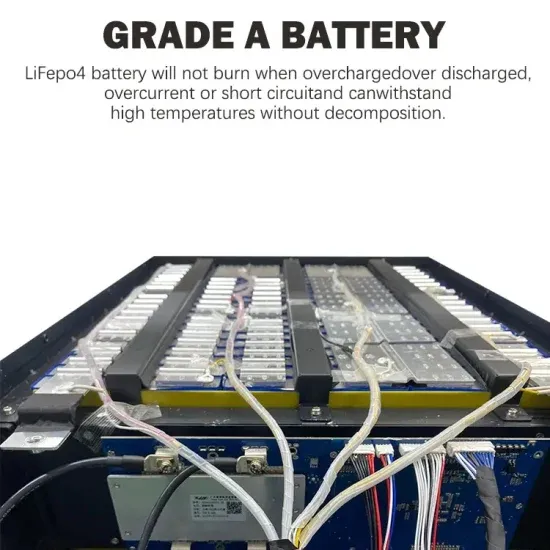

Jan 26, 2024 · The 115kWh air cooling energy storage system cabinet adopts an "All-In-One" design concept, with ultra-high integration that combines energy storage batteries, BMS

Energy Storage System Cooling

May 5, 2025 · Battery back-up systems must be efficiently and effectively cooled to ensure proper operation. Heat can degrade the performance, safety and operating life of battery back-up

Seasonal storage of solar thermal energy through

At the end of the storage process, the compressed air is stored in the high-pressure vessel. The process of energy discharge, which is in the form of cooling operation, can be started

Thermodynamic and economic analysis of a novel compressed air energy

Dec 1, 2024 · The working principle of the CAES system is as follows: during charging, air at ambient temperature and pressure is compressed into high-pressure air by a compressor and

Metal hydride hydrogen storage and compression systems for energy

Apr 9, 2021 · The article also presents features of integrated energy storage systems utilising metal hydride hydrogen storage and compression, as well as their metal hydride based

A novel liquid air energy storage system integrated with a

Oct 15, 2023 · Liquid air energy storage system (LAES) is a promising Carnot battery''s configuration that includes thermal energy storage systems to thermally connect the charge

Solveno Technologies | Liquid Air Energy Storage (LAES)

Aug 14, 2025 · Long-duration Storage: LAES has the potential for long-duration energy storage, making it suitable for storing renewable energy from intermittent sources like wind and solar

A review of air-cooling battery thermal management systems for electric

Jul 31, 2021 · The integration of thermal management with the energy storage (battery) component is one of the most important technical issues to be addressed. The onboard

Liquid air energy storage systems: A review

Aug 1, 2021 · Liquid Air Energy Storage (LAES) systems are thermal energy storage systems which take electrical and thermal energy as inputs, create a thermal energy reservoir, and

Energy and Exergy Analysis of a Micro Compressed Air

Oct 13, 2020 · ABSTRACT Energy storage systems are becoming more important for load leveling, especially for widespread use of intermittent renewable energy. Compressed air

A review of thermal energy storage in compressed air energy storage system

Dec 1, 2019 · During energy release process, the high pressure air stored in the compressed air storage first passes through the combustion chamber, burned mixed with fuel and become

Coupled system of liquid air energy storage and air

Jul 1, 2024 · Liquid air energy storage (LAES) emerges as a promising solution for large-scale energy storage. However, challenges such as extended payback periods,

High-Pressure Air-Cooled Energy Storage Systems: The

If you''ve ever wondered how to store energy without breaking the bank or melting your equipment, high-pressure air-cooled energy storage systems might just be your new best friend.

A cold thermal energy storage based on ASU-LAES system: Energy

Jan 1, 2025 · In the energy storage stage, the cold thermal energy is released from the CTES, while the ASU load increases, which increases the rate of air liquefaction and realizes the

Thermodynamic performance analysis of a new air energy storage

Dec 15, 2024 · Sensitivity analysis indicates that the outlet pressure of the air storage tank and fuel flow are the main influencing parameters for system performance. Increasing the fuel flow

Integrated cooling system with multiple operating modes for

Apr 15, 2025 · Aiming at the problem of insufficient energy saving potential of the existing energy storage liquid cooled air conditioning system, this paper integra

6 FAQs about [High-pressure air-cooled energy storage system]

What is compressed air energy storage (CAES)?

Compressed air energy storage (CAES) is an effective solution for balancing this mismatch and therefore is suitable for use in future electrical systems to achieve a high penetration of renewable energy generation.

What is a liquid air energy storage system?

An overview of this technology can be found in . It is also possible to store large amounts of energy at a smaller size than a CAES system with liquid air energy storage systems (LAES), which store liquid air (or liquid nitrogen) rather than compressed air .

Why do we need compressed air energy storage systems?

Conclusions With excellent storage duration, capacity, and power, compressed air energy storage systems enable the integration of renewable energy into future electrical grids. There has been a significant limit to the adoption rate of CAES due to its reliance on underground formations for storage.

What is an ocean-compressed air energy storage system?

Seymour [98, 99] introduced the concept of an OCAES system as a modified CAES system as an alternative to underground cavern. An ocean-compressed air energy storage system concept design was developed by Saniel et al. and was further analysed and optimized by Park et al. .

What is hybrid thermal-compressed air energy storage?

Using wind power, the system was called hybrid thermal–compressed air energy storage, which further increased the temperature of the heat storage (theoretical analysis indicated the maximum temperature of TES could reach 1273 °C) .

How is compressed air used to store and generate energy?

Using this technology, compressed air is used to store and generate energy when needed . It is based on the principle of conventional gas turbine generation. As shown in Figure 2, CAES decouples the compression and expansion cycles of traditional gas turbines and stores energy as elastic potential energy in compressed air . Figure 2.

Learn More

- North Cyprus air-cooled energy storage project

- Low-pressure air-cooled energy storage system

- Air-cooled 25kw photovoltaic energy storage cabinet

- Air duct of air-cooled energy storage cabinet

- Lithuanian air-cooled energy storage system manufacturer

- Air-cooled container energy storage system

- Bloemfontein air-cooled energy storage system

- Telecom Energy Storage Clean Energy Storage Cabinet Battery Capacity

- Emergency generator can use energy storage station

Industrial & Commercial Energy Storage Market Growth

The global industrial and commercial energy storage market is experiencing explosive growth, with demand increasing by over 250% in the past two years. Containerized energy storage solutions now account for approximately 45% of all new commercial and industrial storage deployments worldwide. North America leads with 42% market share, driven by corporate sustainability initiatives and tax incentives that reduce total project costs by 18-28%. Europe follows closely with 35% market share, where standardized industrial storage designs have cut installation timelines by 65% compared to traditional built-in-place systems. Asia-Pacific represents the fastest-growing region at 50% CAGR, with manufacturing scale reducing system prices by 20% annually. Emerging markets in Africa and Latin America are adopting industrial storage solutions for peak shaving and backup power, with typical payback periods of 2-4 years. Major commercial projects now deploy clusters of 15+ systems creating storage networks with 80+MWh capacity at costs below $270/kWh for large-scale industrial applications.

Industrial Energy System Innovations & Cost Benefits

Technological advancements are dramatically improving industrial energy storage performance while reducing costs. Next-generation battery management systems maintain optimal operating conditions with 45% less energy consumption, extending battery lifespan to 20+ years. Standardized plug-and-play designs have reduced installation costs from $85/kWh to $40/kWh since 2023. Smart integration features now allow multiple industrial systems to operate as coordinated energy networks, increasing cost savings by 30% through peak shaving and demand charge management. Safety innovations including multi-stage fire suppression and thermal runaway prevention systems have reduced insurance premiums by 35% for industrial storage projects. New modular designs enable capacity expansion through simple system additions at just $200/kWh for incremental capacity. These innovations have improved ROI significantly, with commercial and industrial projects typically achieving payback in 3-5 years depending on local electricity rates and incentive programs. Recent pricing trends show standard industrial systems (1-2MWh) starting at $330,000 and large-scale systems (3-6MWh) from $600,000, with volume discounts available for enterprise orders.