Energy storage cabinet air cooling duct structure

Energy storage cabinet air cooling duct structure Does airflow organization affect heat dissipation behavior of container energy storage system? In this paper,the heat dissipation behavior of the

Why Air Duct Design Matters in Air-Cooled Energy Storage

Jun 12, 2025 · Air duct design refers to how airflow is organized inside an energy storage cabinet to control the temperature of lithium iron phosphate (LFP) battery modules. In an air-cooled

Air-cooled safety energy storage cabinet

The invention belongs to the technical field of electric energy storage equipment, and particularly relates to an air-cooled safe energy storage cabinet, which comprises an energy storage

ERISCO Air Cooled Energy Storage Integrated Cabinet –

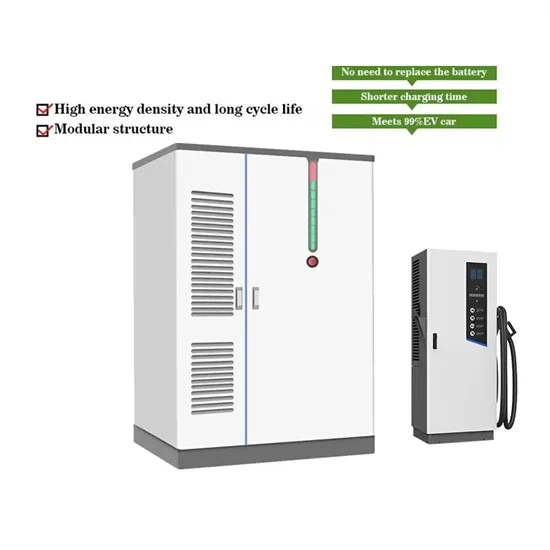

The air-cooled energy storage integrated cabinet system adopts the design concept of "all in one," which integrates long-life battery cells, a high-efficiency balanced BMS, high-performance

Air-cooled circulation energy storage system

The air-cooled circulation energy storage system comprises: an energy storage cabinet, which comprises a housing and a battery compartment arranged in the housing, wherein an air

DESIGN SPECIFICATION FOR AIR DUCT OF OUTDOOR

air duct design of air-cooled energy storage cabinet. 1075kWh Air Cooled Intergrated LFP Battery Energy Storage Cabinet. Main parameters of this outdoor energy storage system are: DC sid

Cabinet type air-cooled energy storage system

The invention discloses a cabinet type air-cooled energy storage system, which comprises a cabinet, a temperature regulating device and a plurality of battery modules, wherein a battery

Smart Ventilation: Optimizing Air Ducts in Lithium Battery ESS Cabinets

Jun 6, 2025 · In air-cooled energy storage systems (ESS), the air duct design refers to the internal structure that directs airflow for thermal regulation of battery modules.

air duct design of air-cooled energy storage cabinet

The 115kWh air cooling energy storage system cabinet adopts an "All-In-One" design concept, with ultra-high integration that combines energy storage batteries, BMS (Battery

Understanding the Air Duct Design in Air-Cooled Energy Storage

Jun 11, 2025 · Air duct design in air-cooled energy storage systems (ESS) refers to the engineering layout of internal ventilation pathways that guide airflow for optimal thermal

Air-cooled circulating energy storage system

The utility model discloses an air-cooled circulating energy storage system, which comprises: the energy storage cabinet comprises an outer shell and a battery compartment arranged in the

Where is the air duct of the energy storage cabinet

Apr 19, 2024 · Air-cooled Energy Storage Cabinet. DC Liquid Cooling Cabinet. Liquid-cooled Energy Storage Cabinet. ESS & PV Integrated Charging Station. Standard Battery Pack. High

Why Air Duct Design Matters in Air-Cooled Energy Storage

Jul 10, 2025 · Air duct design refers to how airflow is organized inside an energy storage cabinet to control the temperature of lithium iron phosphate (LFP) battery modules. In an air-cooled

NTC Temperature Sensor for Lithium Battery Air-Cooled Energy Storage

Aug 21, 2023 · The fan of the lithium battery air-cooled energy storage system is controlled to adjust the heat dissipation balance of the lithium battery air-cooled energy storage system,

Smart Ventilation: Optimizing Air Ducts in Lithium Battery ESS Cabinets

Jun 6, 2025 · What Is Air Duct Design in Air-Cooled ESS? In air-cooled energy storage systems (ESS), the air duct design refers to the internal structure that directs airflow for thermal

Air-cooled energy storage battery cabinet

The utility model relates to a technical field of battery cabinet, concretely relates to forced air cooling energy storage battery cabinet. Including the battery cabinet body, this internal battery

Energy storage cabinet air cooling duct structure

Water-cooled plates are usually welded or coated through the cabinet and the air conditioning system are connected by the upper air duct, allowing cold air to reach both sides of the battery

100kW 215kWh Air Cooled Commercial and Industrial Energy Storage

This 215kWh air cooled distributed energy storage cabinet adopts the all-in-one design, including quality battery pack, efficient BMS, high-performance PCS of patented technology, cloud EMS

Where is the air duct of the energy storage cabinet

The invention discloses an air duct system of an outdoor energy storage battery cabinet, which comprises a circulating air duct device, an air conditioner and a fan, wherein the circulating air

industrial and commercial integrated energy storage cabinet air duct

Outdoor Distributed Energy Storage (Air-cooling) The air-cooled battery cabinet is a distributed energy storage system for industrial and commercial applications.

Experimental and numerical investigation of a composite

Mar 1, 2025 · The "U" air duct type experimental test setup of the air-cooled energy storage battery thermal management was built, which mainly including energy storage battery packs

Where is the air duct of the energy storage cabinet

Apr 19, 2024 · The 215kWh air cooling energy storage system cabinet adopts an "All-In-One" design concept, with ultra-high integration that combines energy storage batteries, BMS

Structure of air-cooled energy storage cabinet

Mar 3, 2024 · The utility model discloses an air cooling heat dissipation structure of an energy storage cabinet, which relates to the technical field of air cooling heat dissipation and

Learn More

- Energy storage container air duct structure

- Energy storage cabinet air cooling system design

- Air-cooled energy storage cabinet introduction site

- Energy storage container battery rack air duct installation

- Huawei Energy Storage Cabinet Air Cooling Solution

- Somalia large energy storage cabinet customization

- Seoul Large Energy Storage Cabinet Supplier

- Myanmar Industrial Energy Storage Cabinet Customized Manufacturer

- Guinea-Bissau Liquid Cooling Energy Storage Cabinet Production

Industrial & Commercial Energy Storage Market Growth

The global industrial and commercial energy storage market is experiencing explosive growth, with demand increasing by over 250% in the past two years. Containerized energy storage solutions now account for approximately 45% of all new commercial and industrial storage deployments worldwide. North America leads with 42% market share, driven by corporate sustainability initiatives and tax incentives that reduce total project costs by 18-28%. Europe follows closely with 35% market share, where standardized industrial storage designs have cut installation timelines by 65% compared to traditional built-in-place systems. Asia-Pacific represents the fastest-growing region at 50% CAGR, with manufacturing scale reducing system prices by 20% annually. Emerging markets in Africa and Latin America are adopting industrial storage solutions for peak shaving and backup power, with typical payback periods of 2-4 years. Major commercial projects now deploy clusters of 15+ systems creating storage networks with 80+MWh capacity at costs below $270/kWh for large-scale industrial applications.

Industrial Energy System Innovations & Cost Benefits

Technological advancements are dramatically improving industrial energy storage performance while reducing costs. Next-generation battery management systems maintain optimal operating conditions with 45% less energy consumption, extending battery lifespan to 20+ years. Standardized plug-and-play designs have reduced installation costs from $85/kWh to $40/kWh since 2023. Smart integration features now allow multiple industrial systems to operate as coordinated energy networks, increasing cost savings by 30% through peak shaving and demand charge management. Safety innovations including multi-stage fire suppression and thermal runaway prevention systems have reduced insurance premiums by 35% for industrial storage projects. New modular designs enable capacity expansion through simple system additions at just $200/kWh for incremental capacity. These innovations have improved ROI significantly, with commercial and industrial projects typically achieving payback in 3-5 years depending on local electricity rates and incentive programs. Recent pricing trends show standard industrial systems (1-2MWh) starting at $330,000 and large-scale systems (3-6MWh) from $600,000, with volume discounts available for enterprise orders.