What Are the Main Cost Components of a PV Combiner Box?

Jan 13, 2025 · Generally, a combiner box needs to be equipped with 1-4 of these, resulting in a cost of 2.58-83.52 USD. These internal electrical components work together to form a complex

ABB megawatt station PVS980-MWS – 3.6 to 4.6

Feb 5, 2020 · A station houses two outdoor 1500 VDC ABB central inverters, an optimized ABB dry type- or oil immersed transformer, MV switchgear, a monitoring system and DC

3 Phases Power Distribution Cabinet 1600A Solar Combiner Box

6 days ago · Fujian Guozhiyun Information Technology Co., Ltd. is a professional company engaged in electrical automation, dedicated to providing customers with overall power

What Are the Main Cost Components of a PV Combiner Box?

Jan 13, 2025 · In today''s era of pursuing clean energy, solar photovoltaic power generation, as a sustainable and pollution free way of energy utilization, is rapidly spreading worldwide. And the

Ground centralized grid connected power station|Zhejiang

Nov 25, 2024 · Large and medium-sized grid connected photovoltaic systems are composed of photovoltaic module arrays, DC combiner boxes, DC cabinets, centralized grid connected

Comparing Central vs String Inverters for Utility

May 14, 2024 · Lower capital expenditure (CAPEX): While string inverter costs have come down, central inverters are usually cheaper upfront (in dollars-per

How much does a solar power station cost per megawatt?

Mar 26, 2024 · The solar power industry stands at a pivotal juncture, characterized by evolving technology, shifting market dynamics, and supportive policies. The cost of solar installations

Pv Combiner Cabinet Factory, Custom Pv Combiner Cabinet

Looking for pv combiner cabinet factory direct sale? You can buy factory price pv combiner cabinet from a great list of reliable China pv combiner cabinet manufacturers, suppliers,

Centralized Photovoltaic Grid-Connected Inverter Market

Jun 23, 2025 · Quick Q&A Table of Contents Infograph Methodology Purchase/Customization Key Drivers Shaping Global Demand for Centralized PV Grid-Tied Inverters Regional markets

Design and Development of 5MW Solar PV Grid

Aug 14, 2017 · Abstract - This study aimed at developing a standard procedure for the design of large-scale (5 MW) grid-connected solar PV systems using the PVSYST Software. The

CATALOG String combiners for solar photovoltaic systems

Mar 16, 2024 · 01 String boxes The installation of a photovoltaic system often occurs in complex logistic situations, critical from the environmental and time perspective. The availability of

How Does a PV Combiner Box Work? | Power

Apr 23, 2024 · AC PV combiner box is an important part to take over the output of string inverter and the input of AC distribution cabinet or step-up transformer,

Virtual central approach of PV string inverters PAP

Mar 22, 2023 · Cost-efficiency is also important factor from the point of view of profitability the PV business investment. As developed based on customers'' needs, LS''s PV combiner boxes

China PV Combiner Box Design Balancing Cost,

Dec 17, 2024 · Our factory offers high quality pv combiner box design balancing cost, efficiency, and reliability made in China with competitive price. Welcome

Solar Inverters: Centralized vs. Distributed

Aug 21, 2013 · In general, a distributed architecture using string inverters yields a slight cost advantage in smaller arrays, while central architectures offer the

CYBWG PV Grid Connected Cabinet|Chiya Electric

Jul 24, 2024 · CYBWG photovoltaic grid-connected cabinet is an important part of undertaking centralized inverter and step-up transformer or AC combiner box and step-up transformer, the

Understanding Domestic Photovoltaic Combiner Box Pricing

When shopping for a residential PV combiner box, you''ll find quotes ranging from ¥22 for basic models to ¥8,075 for industrial-grade units. This 366x price difference isn''t random - it''s your

Virtual Central approach of PV string inverters – a cost

Oct 7, 2021 · The virtual central inverters are mounted on an inverter rack adjacent to the AC station. In the comparison at hand, it is even the more expensive variant with a DC combiner

6 FAQs about [Centralized PV box-type transformer combiner cabinet cost per megawatt]

How Kaco New Energy uses combiner boxes?

KACO new energy uses combiner boxes to support you with very flexible system design. First and foremost, DC combiners enable the "Virtual Central" concept: In ground-mounted solar power plants, the inverters are installed at a central location, while the DC combiners are spread across the PV module array.

What is a DC combiner box?

The DC combiner box collects the output of the PV panels (for instance 30 modules per string) and is usually mounted at the substructure of the PV panels. In our simulation, a DC combiner box with 20 string inputs has been selected. The connection between the DC combiner and the inverter is via 2x1500 V DC underground cables.

What is the difference between a PV module and a transformer?

Instead, we focus on those elements which have cost differences: Basically, the electrical system between the PV modules and the transformer consists of inverters, inverter mounting, DC combiner boxes, AC cabinets, AC combiner boxes and cabling.

How are PV DC combiner boxes tested?

PV DC combiner boxes are tested according to IEC-61439-2 and are constructed on the basis of the test results as well as assembled for the specific application. This ensures that each of the requirements of the target application is fully met.

Does KACO offer combiner boxes?

This site is protected by reCAPTCHA and the Google Privacy Policy and Terms of Service apply. For flexibility in system design and specific safety aspects of C&I PV systems and utility-scale solar power plants, KACO new energy offers combiner boxes as matching equipment for its inverters.

Why should you choose LS solar combiner boxes?

As developed based on customers’ needs, LS’s PV combiner boxes provide optimum connections and protections from the modules to the inverters. High reliability and safety. Optimized for solar power plants. The enclosure was made of metal (SS304) to increase durability. It is designed based on the latest IEC standards and has been certified as CB.

Learn More

- Amman PV combiner box

- How much does it cost to order a storage cabinet container in the United Arab Emirates

- How much does a box-type energy storage system cost

- 20MW base station energy storage cabinet cost

- ASEAN Industrial and Commercial Energy Storage Cabinet Cost

- Nassau Solar PV Panel Purchase Cost

- Which PV combiner box is the best in Indonesia

- How much does a lithium battery cost in an energy storage cabinet

- Energy storage cabinet cost control measures

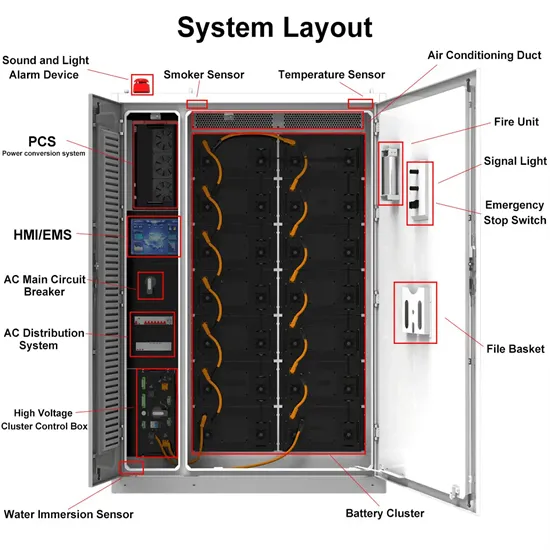

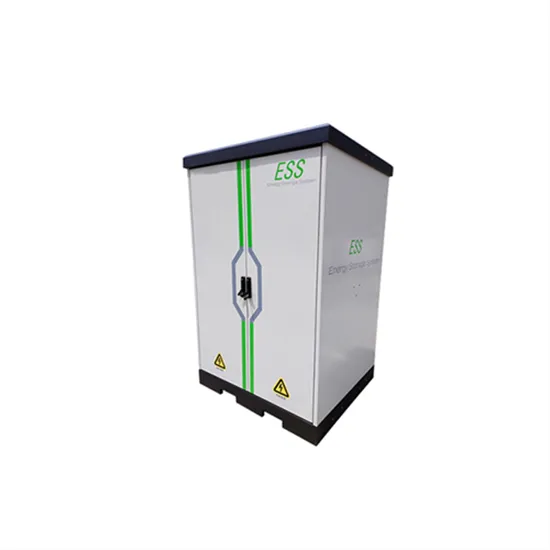

Industrial & Commercial Energy Storage Market Growth

The global industrial and commercial energy storage market is experiencing explosive growth, with demand increasing by over 250% in the past two years. Containerized energy storage solutions now account for approximately 45% of all new commercial and industrial storage deployments worldwide. North America leads with 42% market share, driven by corporate sustainability initiatives and tax incentives that reduce total project costs by 18-28%. Europe follows closely with 35% market share, where standardized industrial storage designs have cut installation timelines by 65% compared to traditional built-in-place systems. Asia-Pacific represents the fastest-growing region at 50% CAGR, with manufacturing scale reducing system prices by 20% annually. Emerging markets in Africa and Latin America are adopting industrial storage solutions for peak shaving and backup power, with typical payback periods of 2-4 years. Major commercial projects now deploy clusters of 15+ systems creating storage networks with 80+MWh capacity at costs below $270/kWh for large-scale industrial applications.

Industrial Energy System Innovations & Cost Benefits

Technological advancements are dramatically improving industrial energy storage performance while reducing costs. Next-generation battery management systems maintain optimal operating conditions with 45% less energy consumption, extending battery lifespan to 20+ years. Standardized plug-and-play designs have reduced installation costs from $85/kWh to $40/kWh since 2023. Smart integration features now allow multiple industrial systems to operate as coordinated energy networks, increasing cost savings by 30% through peak shaving and demand charge management. Safety innovations including multi-stage fire suppression and thermal runaway prevention systems have reduced insurance premiums by 35% for industrial storage projects. New modular designs enable capacity expansion through simple system additions at just $200/kWh for incremental capacity. These innovations have improved ROI significantly, with commercial and industrial projects typically achieving payback in 3-5 years depending on local electricity rates and incentive programs. Recent pricing trends show standard industrial systems (1-2MWh) starting at $330,000 and large-scale systems (3-6MWh) from $600,000, with volume discounts available for enterprise orders.