Energy storage system cost breakdown chart

The 2020 Cost and Performance Assessment provided installed costs for six energy storage technologies: lithium-ion (Li-ion) batteries, lead-acid batteries, vanadium redox flow batteries,

How much does Shanghai energy storage equipment cost?

May 29, 2024 · Shanghai energy storage equipment costs can vary considerably based on several factors: 1, technology type, 2, capacity, 3, manufacturer, 4, installation requirements.

Box Pricing & Plans (2025 Guide)

Jan 7, 2025 · How Much Does Box Cost? Box offers a variety of pricing plans to cater to different business needs, from small teams to large enterprises. Below is a detailed breakdown of Box''s

DOE ESHB Chapter 25: Energy Storage System Pricing

Sep 3, 2021 · Abstract Comparing the costs of rapidly maturing energy storage technologies poses a challenge for customers purchasing these systems. There is a need for a trusted

What Is The Current Average Cost Of Energy Storage Systems

Jul 9, 2025 · In 2025, the average energy storage cost ranges from $200 to $400 per kWh, with total system prices varying by technology, region, and installation factors.

How much does a factory energy storage system cost?

May 20, 2024 · The cost of a factory energy storage system typically involves several factors that can significantly affect the overall price. These include: 1. Type of technology used in the

BESS Costs Analysis: Understanding the True Costs of Battery Energy

Aug 29, 2024 · As of recent data, the average cost of a BESS is approximately $400-$600 per kWh. Here''s a simple breakdown: This estimation shows that while the battery itself is a

1MW Battery Energy Storage System

5 days ago · The MEGATRON 1MW Battery Energy Storage System (AC Coupled) is an essential component and a critical supporting technology for smart grid and renewable energy (wind and

Energy storage cost – analysis and key factors to consider

5 days ago · This article provides an analysis of energy storage cost and key factors to consider. It discusses the importance of energy storage costs in the context of renewable energy

What is the Cost of BESS per MW? Trends and 2025 Forecast

Feb 26, 2025 · Introduction: The Ever-Changing Cost of Battery Energy Storage Systems (BESS) Battery Energy Storage Systems (BESS) are a game-changer in renewable energy. How

6 FAQs about [How much does a box-type energy storage system cost ]

What is energy storage price?

The price is the expected installed capital cost of an energy storage system. Because the capital cost of these systems will vary depending on the power (kW) and energy (kWh) rating of the system, a range of system prices is provided. 2. Evolving System Prices

What are the different types of energy storage systems?

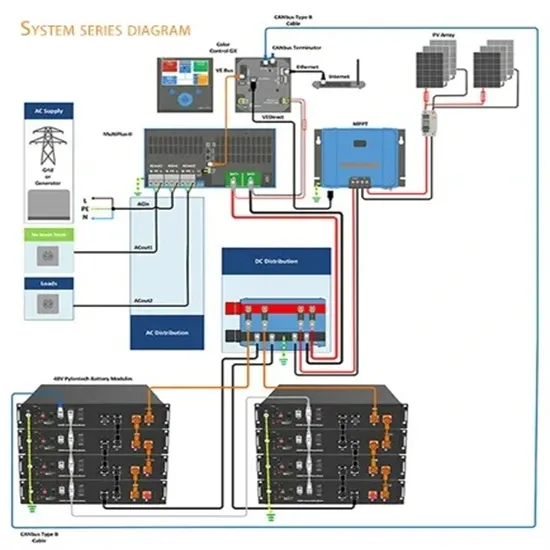

The survey methodology breaks down the cost of an energy storage system into the following categories: storage module, balance of system, power conversion system, energy management system, and the engineering, procurement, and construction costs.

How much does a gas storage system cost?

Generally speaking, the cost of the gas storage tank is the most expensive part of the entire system. Operation and maintenance costs include energy consumption and equipment maintenance. The current cost of compressed air energy storage systems is between US$500-1,000/kWh.

Are battery energy storage systems worth the cost?

Battery Energy Storage Systems (BESS) are becoming essential in the shift towards renewable energy, providing solutions for grid stability, energy management, and power quality. However, understanding the costs associated with BESS is critical for anyone considering this technology, whether for a home, business, or utility scale.

Does energy storage cost a lot?

The cost of energy storage is a crucial aspect to consider when evaluating the feasibility and scalability of renewable energy systems. With ongoing advancements and cost reductions, energy storage is poised to play a pivotal role in enabling a sustainable energy future.

Are battery electricity storage systems a good investment?

This study shows that battery electricity storage systems offer enormous deployment and cost-reduction potential. By 2030, total installed costs could fall between 50% and 60% (and battery cell costs by even more), driven by optimisation of manufacturing facilities, combined with better combinations and reduced use of materials.

Learn More

- How much does 1kwh of energy storage cost now

- How much does the Cape Verde energy storage system cost

- How much does the Nouakchott energy storage device cost

- How much does household energy storage battery cost in Kazakhstan

- How much does photovoltaic energy storage cost per kilowatt-hour

- How much does a container energy storage cabinet cost in Ethiopia

- How much does the London energy storage battery cost

- How much does a Syrian household energy storage power supply cost

- How much does a wind-solar hybrid energy storage cabinet for a communication base station cost

Industrial & Commercial Energy Storage Market Growth

The global industrial and commercial energy storage market is experiencing explosive growth, with demand increasing by over 250% in the past two years. Containerized energy storage solutions now account for approximately 45% of all new commercial and industrial storage deployments worldwide. North America leads with 42% market share, driven by corporate sustainability initiatives and tax incentives that reduce total project costs by 18-28%. Europe follows closely with 35% market share, where standardized industrial storage designs have cut installation timelines by 65% compared to traditional built-in-place systems. Asia-Pacific represents the fastest-growing region at 50% CAGR, with manufacturing scale reducing system prices by 20% annually. Emerging markets in Africa and Latin America are adopting industrial storage solutions for peak shaving and backup power, with typical payback periods of 2-4 years. Major commercial projects now deploy clusters of 15+ systems creating storage networks with 80+MWh capacity at costs below $270/kWh for large-scale industrial applications.

Industrial Energy System Innovations & Cost Benefits

Technological advancements are dramatically improving industrial energy storage performance while reducing costs. Next-generation battery management systems maintain optimal operating conditions with 45% less energy consumption, extending battery lifespan to 20+ years. Standardized plug-and-play designs have reduced installation costs from $85/kWh to $40/kWh since 2023. Smart integration features now allow multiple industrial systems to operate as coordinated energy networks, increasing cost savings by 30% through peak shaving and demand charge management. Safety innovations including multi-stage fire suppression and thermal runaway prevention systems have reduced insurance premiums by 35% for industrial storage projects. New modular designs enable capacity expansion through simple system additions at just $200/kWh for incremental capacity. These innovations have improved ROI significantly, with commercial and industrial projects typically achieving payback in 3-5 years depending on local electricity rates and incentive programs. Recent pricing trends show standard industrial systems (1-2MWh) starting at $330,000 and large-scale systems (3-6MWh) from $600,000, with volume discounts available for enterprise orders.