电池异常充电测试实验室,为您解读异常充电测试要求

Overvoltage charging protection Overcurrent charging protection Undervoltage discharge protection Short circuit protection test Overload protection test Over temperature protection

BATTERY INSPECTION CHECKLIST

Oct 10, 2024 · Note: Battery should be Replaced if ~ Point 2,4 & 7: Badly damage ~ Point 16: < 6,5 VDC or < 300A Battery should be Recharged if ~ All Visual Inspection OK ~ Point 16 in

Liebert® GXT5 Installer/User Guide

Mar 20, 2020 · To ensure adequate back-up time, charge the batteries for at-least 8 hours before first start-up. NOTE: If utility power fails and the batteries are charged, you may cold-start the

A METHOD FOR ABNORMAL BATTERY CHARGING CAPACITY

FAQS about Battery charging cabinet maintenance method How can a battery charging and storage cabinet improve safety? A battery charging and storage cabinet that''s been electrically

Understanding IEC 60086-4: Safety Standard Primary Lithium Batteries

Feb 7, 2025 · Specific Testing Requirements for IEC 60086-4 Lithium Batteries Specific standard safety tests must be carried out for lithium batteries to be considered safe for use and to

Understanding and Troubleshooting Abnormal EV Battery Charging

Aug 19, 2025 · Real-World Impact Imagine preparing for an important road trip only to discover your EV stubbornly refuses to charge beyond 60%. This scenario, experienced by many

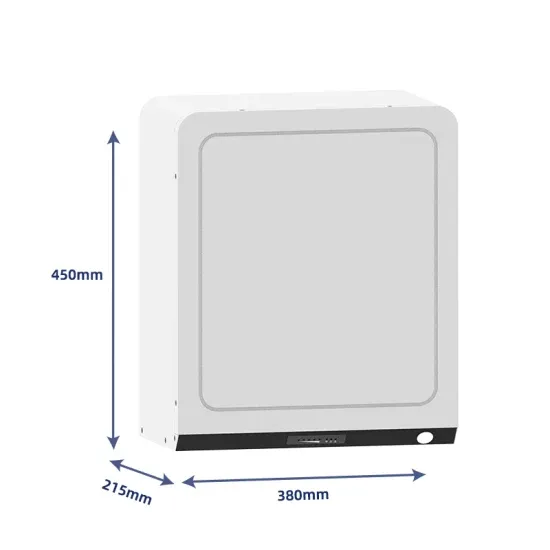

ESS Battery Cell Performance Testing Cabinet

Brief Description The ESS Battery Cell Performance Testing Cabinet is a high-precision system designed to evaluate the electrical and thermal performance of energy storage system (ESS)

UL2054标准,沃特带您一起精准解读!

Jul 13, 2021 · 电池包中的电源板元件需要依次进行失效(除了符合UL1434或者UL60730-1A认证的元件以外,因为标准判定这两个标准认证的元件符合安全规

Energy Efficiency Battery Charger System Test Procedure

Apr 6, 2022 · Scope A. General Scope The purpose of the test procedure is to measure the energy efficiency of battery chargers coupled with their batteries, which together are referred

Top Standards for Lithium Battery Safety Testing

Abusive Overcharge Test of UL2054: 1. The lithium-ion batteries are to be tested in an ambient temperature of 20 ±5°C (68 ±9°F). 2. Lithium-ion batteries are to be subjected to a continuous

Top Standards for Lithium Battery Safety Testing

May 12, 2021 · Today we are going to discuss about the UL 2054– UL Standard for Safety of Lithium Batteries (the abnormal charging test). UL 2054. Abnormal charging test: 1. Lithium

Choosing the Right Lithium Ion Battery Cabinet:

May 1, 2025 · The right lithium ion battery cabinet is a vital investment for any business using rechargeable power systems. It protects against fire, enhances

General overview on test standards for Li-ion batteries,

A 2023 DNV report revealed that battery cabinet testing procedures fail to detect 12% of thermal runaway risks in commercial installations. This gap directly correlates with the 27% year-on

Understanding IEC 60086-4: Safety Standard Primary Lithium Batteries

Feb 7, 2025 · Below are some of these standard tests: This test checks the battery''s reaction when incorrectly charged. The "abnormal charging" test is important so that if the end-user

Safety Issues for Lithium-Ion Batteries

Jun 27, 2023 · Abnormal Charging or Overcharging Test — The abnormal charging test applies an over-charging current rate and charging time to determine whether a sample can withstand

Top Standards for Lithium Battery Safety Testing

For lithium batteries, there are some popular standards that Battery Lab tests to most often. In this sequel of articles we are going to discuss about these popular standards one by one. Today

Failure Analysis of Electric Vehicle AC Charging Piles

Jun 23, 2025 · The AC charging connection device is not properly connected; there is a fault in the charging pile circuit. 1.1.2 Fault Diagnosis & Troubleshooting Diagnosis flow as Figure 1.

Lithium battery safety explosion-proof cabinet test

A battery cabinet is a particular type of storage cabinet that reduces the risks associated with lithium-ion batteries. These innovative cabinets create a safer environment in which

UL 2054检测项目及检测方法

Dec 5, 2022 · Abnormal Charging Test 判定依据: 测试期间样品不能着火,测试样品测试期间不能出现因样品破裂而引起的化学品泄漏。 测试方法: 电池包需要在20°C的环境温度下连续充

lithium batteries,lithium-ion battery,Lithium-ion batteries

For lithium batteries, there are some popular standards that Battery Lab tests to most often. In this sequel of articles we are going to discuss about these popular standards one by one. Today

Learn More

- Battery cabinet adjustable power supply charging

- Battery cabinet and charging power

- Battery cabinet charging and discharging 2 2KWH method

- Battery cabinet withstand voltage test photovoltaic current

- Charging pile lithium battery storage cabinet customization

- New Energy Battery Cabinet Test Standards

- Battery cabinet power test report

- Nouakchott energy storage cabinet battery charging

- Lithium battery station cabinet charging

Industrial & Commercial Energy Storage Market Growth

The global industrial and commercial energy storage market is experiencing explosive growth, with demand increasing by over 250% in the past two years. Containerized energy storage solutions now account for approximately 45% of all new commercial and industrial storage deployments worldwide. North America leads with 42% market share, driven by corporate sustainability initiatives and tax incentives that reduce total project costs by 18-28%. Europe follows closely with 35% market share, where standardized industrial storage designs have cut installation timelines by 65% compared to traditional built-in-place systems. Asia-Pacific represents the fastest-growing region at 50% CAGR, with manufacturing scale reducing system prices by 20% annually. Emerging markets in Africa and Latin America are adopting industrial storage solutions for peak shaving and backup power, with typical payback periods of 2-4 years. Major commercial projects now deploy clusters of 15+ systems creating storage networks with 80+MWh capacity at costs below $270/kWh for large-scale industrial applications.

Industrial Energy System Innovations & Cost Benefits

Technological advancements are dramatically improving industrial energy storage performance while reducing costs. Next-generation battery management systems maintain optimal operating conditions with 45% less energy consumption, extending battery lifespan to 20+ years. Standardized plug-and-play designs have reduced installation costs from $85/kWh to $40/kWh since 2023. Smart integration features now allow multiple industrial systems to operate as coordinated energy networks, increasing cost savings by 30% through peak shaving and demand charge management. Safety innovations including multi-stage fire suppression and thermal runaway prevention systems have reduced insurance premiums by 35% for industrial storage projects. New modular designs enable capacity expansion through simple system additions at just $200/kWh for incremental capacity. These innovations have improved ROI significantly, with commercial and industrial projects typically achieving payback in 3-5 years depending on local electricity rates and incentive programs. Recent pricing trends show standard industrial systems (1-2MWh) starting at $330,000 and large-scale systems (3-6MWh) from $600,000, with volume discounts available for enterprise orders.