Direct Current Load Banks for Battery Capacity Testing

Jun 21, 2023 · The Need for Capacity Testing Battery capacity is the measure of energy that a battery can store. Capacity testing verifies that the battery can deliver its rated power when

IEC62477_1A

Jan 6, 2024 · The test results presented in this report relate only to the object tested. This report shall not be reproduced, except in full, without the written approval of the Issuing CB Testing

Inspection and Test Plan for UPS, Batteries & DC

2 – ITP – Inspection And Test Plan for UPS, Batteries & DC Chargers Installation The complete table of inspection and testing activities with responsibilities,

UL-1973 Certification and Battery Components

Apr 24, 2023 · How TÜV SÜD Can Help e of ESS testing and certification services. These services benefit ESS end users, such as electrical utility companies and commercial

Energy Storage Cabinet Product Test Report: What You

Why Your Battery Cabinet''s Test Report Matters More Than You Think Ever wondered what keeps your energy storage cabinet from turning into a modern-day Icarus? (Spoiler: It''s not

BATTERY INSPECTION CHECKLIST

Oct 10, 2024 · Note: Battery should be Replaced if ~ Point 2,4 & 7: Badly damage ~ Point 16: < 6,5 VDC or < 300A Battery should be Recharged if ~ All Visual Inspection OK ~ Point 16 in

New lithium-ion battery cabinet passes UL 9540A test

Mar 1, 2025 · New lithium-ion battery cabinet completes UL 9540A test Lithium-ion batteries have risen quickly in popularity for Uninterruptible Power Supply (UPS) applications because of their

Top 10 Battery Test Equipment Brands: Comparison and

Feb 8, 2025 · Top 10 Battery Test Equipment Brands: Comparison and Selection Guide Like humans, everything in the electrical and electronics world needs a power supply to perform its

Battery Cabinet Testing Procedures | HuiJue Group E-Site

A 2023 DNV report revealed that battery cabinet testing procedures fail to detect 12% of thermal runaway risks in commercial installations. This gap directly correlates with the 27% year-on

Overview of EV battery testing and evaluation of EES systems

Sep 1, 2023 · Therefore, the testing of the power battery becomes especially important [7], [8]. To address the above challenges, based on the existing technical means of EV battery testing,

Test Systems for Electrical Energy Storage

Feb 20, 2019 · E-mobility is a worldwide automobile mega trend. In the field of mobile systems, lithium-ion batteries have successfully prevailed as energy storage device. Ever larger

Samsung UL9540A Lithium-ion Battery Energy Storage

Feb 19, 2021 · Overview The Samsung SDI 128S and 136S energy storage systems for data center application are the first lithium-ion battery cabinets to fulfill the rack-level safety

Microsoft Word

Jun 3, 2020 · This report shall not be reproduced, except in full, without the written approval of the Issuing CB Testing Laboratory. The authenticity of this Test Report and its contents can be

Samsung UL9540A Lithium-ion Battery Energy Storage

Jan 25, 2018 · Overview The Samsung SDI 128S and 136S energy storage systems for data center application are the first lithium-ion battery cabinets to fulfill the rack-level safety

TEST REPORT IEC 62619 Secondary cells and batteries

Nov 8, 2023 · TEST REPORT IEC 62619 Secondary cells and batteries containing alkaline or other non-acid electrolytes Safety requirements for secondary lithium cells and batteries, for

General overview on test standards for Li-ion batteries,

Nov 7, 2017 · This table covers test standards for Li-ion batteries. It is made in the European projects eCaiman, Spicy and Naiades. batterystandards

What is the energy storage module testing cabinet

What is a battery energy storage system? Battery Energy Storage Systems (BESS) are expected to be an integral component of future electric grid solutions. Testing is needed to verify that

6 FAQs about [Battery cabinet power test report]

Can a CB test report be reproduced?

General disclaimer: The test results presented in this report relate only to the object tested. This report shall not be reproduced, except in full, without the written approval of the Issuing CB Testing La-boratory. The authenticity of this Test Report and its contents can be verified by contacting the NCB, re-sponsible for this Test Report.

Is a report valid as a CB test report?

is report is not valid as a CB Test Report unless signed by an approved IEC E Testing Laboratory and appended to a CB Test Certificate issued by an NCB in accordance with IECEE 2. General disclaimer:The test results presented in this report relate only to the object tested.This report shall not be re duced, except in full, without the written ap

What happens after a battery test?

After the test (Charging temp. Upper limit 45°C): Fire: the emission of flames from a cell or battery. Explosion: failure that occurs when a cell container or battery case opens violently and major components are forcibly expelled. Fire: the emission of flames from a cell or battery.

For how long should a battery be kept on test?

The battery pack should remain on test for an additional one hour if the short circuit current shows a rapid decline. This typically refers to a condition where the per cell voltage (series cells only) of the battery is below 0,8 V and is decreasing by less than 0,1 V in a 30-minute period. In such a case, the battery should be kept on test for a total duration of one hour and thirty minutes.

Are lithium ion batteries safe for transport?

According to the UN Recommendations on the Transport of Dangerous Goods, regulations for international transport of lithium ion batteries include testing requirements as outlined in the UN Manual of Tests & Criteria. Results showed no fire during the tests.

How do I know if my equipment complies with the PWB test?

the equipment complies with the PWB short circuit test (see 5.2.4.7). In this case the manufacture specification may be used. Compliance is checked by inspection and by test of 5.2.4.7 if applicable. Materials selected for solid insulation shall be able to withstand the stresses occurring.

Learn More

- High power battery cabinet aging test

- The battery in the energy storage cabinet is out of power

- New energy battery cabinet is not base station power

- Is the new energy battery cabinet AC power

- Outdoor Energy Storage Power Battery Cabinet

- Tiraspol outdoor communication battery cabinet power

- How to calculate power and current in battery cabinet

- Energy storage cabinet battery power 215KWh

- Kigali New Energy Battery Cabinet Base Station Power Generation Store

Industrial & Commercial Energy Storage Market Growth

The global industrial and commercial energy storage market is experiencing explosive growth, with demand increasing by over 250% in the past two years. Containerized energy storage solutions now account for approximately 45% of all new commercial and industrial storage deployments worldwide. North America leads with 42% market share, driven by corporate sustainability initiatives and tax incentives that reduce total project costs by 18-28%. Europe follows closely with 35% market share, where standardized industrial storage designs have cut installation timelines by 65% compared to traditional built-in-place systems. Asia-Pacific represents the fastest-growing region at 50% CAGR, with manufacturing scale reducing system prices by 20% annually. Emerging markets in Africa and Latin America are adopting industrial storage solutions for peak shaving and backup power, with typical payback periods of 2-4 years. Major commercial projects now deploy clusters of 15+ systems creating storage networks with 80+MWh capacity at costs below $270/kWh for large-scale industrial applications.

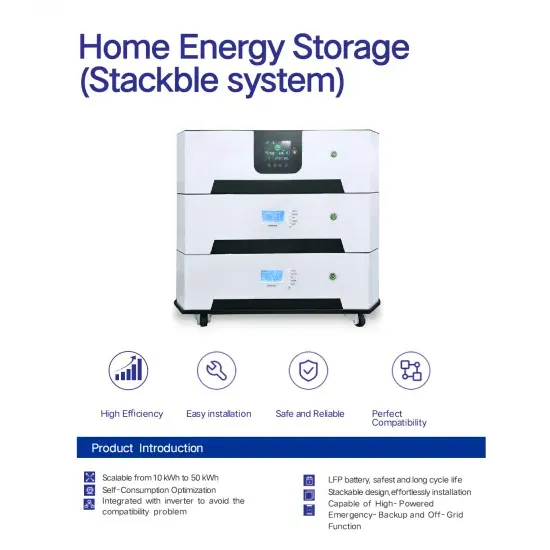

Industrial Energy System Innovations & Cost Benefits

Technological advancements are dramatically improving industrial energy storage performance while reducing costs. Next-generation battery management systems maintain optimal operating conditions with 45% less energy consumption, extending battery lifespan to 20+ years. Standardized plug-and-play designs have reduced installation costs from $85/kWh to $40/kWh since 2023. Smart integration features now allow multiple industrial systems to operate as coordinated energy networks, increasing cost savings by 30% through peak shaving and demand charge management. Safety innovations including multi-stage fire suppression and thermal runaway prevention systems have reduced insurance premiums by 35% for industrial storage projects. New modular designs enable capacity expansion through simple system additions at just $200/kWh for incremental capacity. These innovations have improved ROI significantly, with commercial and industrial projects typically achieving payback in 3-5 years depending on local electricity rates and incentive programs. Recent pricing trends show standard industrial systems (1-2MWh) starting at $330,000 and large-scale systems (3-6MWh) from $600,000, with volume discounts available for enterprise orders.