Energy Storage Container Installation Tips | Enerlution

Aug 4, 2024 · For those looking to harness the full potential of energy storage containers, understanding the nuances of their installation process is crucial. In this article, we''ll dive deep

Installation Process of Energy Storage Container: A Step-by

Whether you''re an engineer working on utility-scale projects or a facility manager handling commercial energy storage container installations, this guide cuts through the technical jargon

What are the heat management methods in container energy storage?

Jun 6, 2025 · Liquid cooling is another effective heat management method, especially for large - scale container energy storage systems. In a liquid cooling system, a coolant (usually water or

Energy storage battery container installation process

Delta offers Energy Storage Systems (ESS) solution, backed by over 50 years of industry expertise. Delta''''s LFP battery container, suitable for grid-scale and medium to large

Container energy storage component installation tutorial

What is a containerized battery energy storage system? Let''s dive in! What are containerized BESS? Containerized Battery Energy Storage Systems (BESS) are essentially large batteries

What are the installation requirements for energy storage containers

In this blog, I will delve into the installation requirements for energy storage containers, covering aspects such as site selection, electrical connections, safety measures, and environmental

Full-scale walk-in containerized lithium-ion battery energy storage

Dec 1, 2022 · Three installation-level lithium-ion battery (LIB) energy storage system (ESS) tests were conducted to the specifications of the UL 9540A standard test method [1]. Each test

Commercial Energy Storage Installation: Key

Mar 27, 2025 · Discover best practices for commercial energy storage installation, including site selection, battery choice, and seamless grid integration for

Explosion Control Guidance for Battery Energy Storage

4 days ago · EXECUTIVE SUMMARY Lithium-ion battery (LIB) energy storage systems (BESS) are integral to grid support, renewable energy integration, and backup power. However, they

Container energy storage component installation tutorial

Let''s dive in! What are containerized BESS? Containerized Battery Energy Storage Systems (BESS) are essentially large batteries housed within storage containers. These systems are

Two Fire Extinguishing Systems for Energy Storage Containers

Jun 28, 2023 · The specific methods and steps are as follows: Protecting the battery pack with micro lithium battery aerosol fire extinguishers. Use a power bank style or box-type

3440kWh Containerized Energy Storage System (Liquid

The 3440kWh Containerized Energy Storage System with liquid cooling is an advanced solution for large energy storage needs. The system integrates high-performance lithium iron

Airflow reorganization and thermal management in a large

Nov 1, 2024 · The present paper numerically investigates the air-cooling thermal management in a large space energy storage container in which packs of high-power d

Large Energy Storage System (above MW level)

The battery energy storage systems are based on standard sea freight containers starting from kW/kWh (single container) up to MW/MWh (combining multiple containers). The containerised

5mwh Battery Container System Large Battery

4 days ago · Battery energy storage system container integrated with a liquid-cooling system, provides high efficiency and flexibility for the utility-scale. With

Energy Storage Container Safety Standards | Enerlution

Aug 14, 2024 · Safety standards for energy storage containers serve as the foundational guidelines to ensure that energy storage systems operate reliably and securely. These

Site-Specific Measures for Large-Scale Lithium Battery Energy Storage

Aug 13, 2025 · Explore the critical safety measures for large-scale lithium battery energy storage systems (BESS), including fire suppression, toxic fume mitigation, and emergency response

White Paper Ensuring the Safety of Energy Storage

Apr 24, 2023 · Introduction Energy storage systems (ESS) are essential elements in global eforts to increase the availability and reliability of alternative energy sources and to reduce our

Large-scale Solar Energy Storage System Solution

Jan 10, 2024 · The energy storage system includes LiFePO4 batteries, BMS, EMS, to PCS, AC/DC distribution cabinets, fire protection systems, lighting discharge monitor power, the

Large Energy Storage Container Installation Method

What is containerized energy storage? ABB''s containerized energy storage solution is a complete,self-contained battery solution for a large-scale marine energy storage. The batteries

Fact Sheet | Energy Storage (2019) | White Papers | EESI

Feb 22, 2019 · Pumped-Storage Hydropower Pumped-storage hydro (PSH) facilities are large-scale energy storage plants that use gravitational force to generate electricity. Water is

Installation process of energy storage container

Installation process of energy storage container A battery energy storage system (BESS) captures energy from renewable and non-renewable sources and stores it in rechar. eable batteries

6 FAQs about [Large Energy Storage Container Installation Method]

How to install a containerized energy storage system?

Use an insulating heat-shrinkable tube for secure terminal fit and label wires clearly. Clean up any foreign objects in the distribution cabinet. Connect all metal shells within the energy storage box to form a grounding network using good conductors or dedicated grounding strips. 6. Containerized Energy Storage System Installation Complete

What are the steps in energy storage installation?

The main steps are: to build the foundation, install the energy storage cabinets, install the battery and inverter, and wire it all. During the commissioning of an energy storage system, which tests does the team perform? System-wide joint commissioning.

What are the sections of energy storage project guide?

The guide is divided into three main sections: construction and installation, commissioning, and operation & maintenance. It covers various aspects such as foundation construction, battery and inverter installation, wiring, system testing, monitoring, fault handling, and preventive maintenance. 1. Energy Storage Project Construction 2.

How do you test an energy storage system?

Measure voltage of the emergency power supply. Calibrate SOC parameters of the battery management system. Test charging and discharging times of the energy storage unit. The C&I Energy Storage: Construction, Commissioning, and O&M Guide is a valuable resource. It is for those deploying and managing energy storage systems.

What is C&I energy storage?

The Industrial and Commercial (C&I) Energy Storage: Construction, Commissioning, and O&M Guide provides a detailed overview of the processes involved in building, commissioning, and maintaining energy storage systems for industrial and commercial applications.

What is energy storage platform & how does it work?

The platform connects global energy storage projects for intelligent O&M. It allows monitoring of project operations and battery performance. The platform gathers data to maximize its value, aiding in optimizing designs and extending service life.

Learn More

- Container energy storage cabinet installation

- Energy storage container battery rack air duct installation

- Container energy storage lithium battery installation

- Installation of photovoltaic energy storage container

- Lithium-ion battery energy storage container installation in Antananarivo

- Telecom Battery Energy Storage Container Installation

- Swedish container energy storage lithium battery installation

- Container Energy Storage Project Plan

- Berlin container energy storage cabinet customization

Industrial & Commercial Energy Storage Market Growth

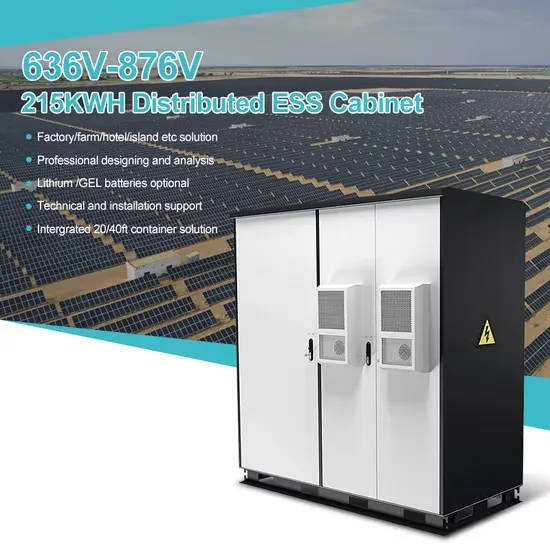

The global industrial and commercial energy storage market is experiencing explosive growth, with demand increasing by over 250% in the past two years. Containerized energy storage solutions now account for approximately 45% of all new commercial and industrial storage deployments worldwide. North America leads with 42% market share, driven by corporate sustainability initiatives and tax incentives that reduce total project costs by 18-28%. Europe follows closely with 35% market share, where standardized industrial storage designs have cut installation timelines by 65% compared to traditional built-in-place systems. Asia-Pacific represents the fastest-growing region at 50% CAGR, with manufacturing scale reducing system prices by 20% annually. Emerging markets in Africa and Latin America are adopting industrial storage solutions for peak shaving and backup power, with typical payback periods of 2-4 years. Major commercial projects now deploy clusters of 15+ systems creating storage networks with 80+MWh capacity at costs below $270/kWh for large-scale industrial applications.

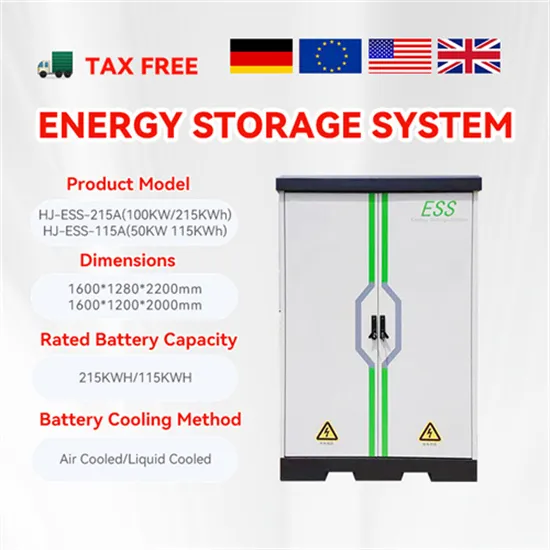

Industrial Energy System Innovations & Cost Benefits

Technological advancements are dramatically improving industrial energy storage performance while reducing costs. Next-generation battery management systems maintain optimal operating conditions with 45% less energy consumption, extending battery lifespan to 20+ years. Standardized plug-and-play designs have reduced installation costs from $85/kWh to $40/kWh since 2023. Smart integration features now allow multiple industrial systems to operate as coordinated energy networks, increasing cost savings by 30% through peak shaving and demand charge management. Safety innovations including multi-stage fire suppression and thermal runaway prevention systems have reduced insurance premiums by 35% for industrial storage projects. New modular designs enable capacity expansion through simple system additions at just $200/kWh for incremental capacity. These innovations have improved ROI significantly, with commercial and industrial projects typically achieving payback in 3-5 years depending on local electricity rates and incentive programs. Recent pricing trends show standard industrial systems (1-2MWh) starting at $330,000 and large-scale systems (3-6MWh) from $600,000, with volume discounts available for enterprise orders.