Battery cabinets are process materials

What is the battery manufacturing process? The battery manufacturing process is a complex sequence of steps transforming raw materials into functional, reliable energy storage units.

Battery cabinets are process materials

A battery enclosure is a housing, cabinet, or box. It is specifically designed to store or isolate the batteryand all its accessories from the external environment. The enclosures come in different

Energy storage cabinet production and processing

Nov 30, 2022 · Breakthroughs have been made in a variety of energy storage technologies. Lithium-ion batterydevelopment trends continued toward greater capacities and longer

China Lithium Battery Storage Cabinet, Lithium Battery Storage Cabinet

China Lithium Battery Storage Cabinet wholesale - Select 2025 high quality Lithium Battery Storage Cabinet products in best price from certified Chinese manufacturers, suppliers,

Lithium battery energy storage cabinet processing

The Vertiv HPL lithium-ion battery cabinet is a safe,reliable,and cost-effective solution for high-power energy storage. It offers improved performance over traditional valve-regulated lead

Energy storage cabinet production and processing

Nov 30, 2022 · Energy storage cabinet processing technologies involve several advanced methods for efficiently storing and managing electrical energy, including 1. lithium-ion battery

Eaton Introduces New Samsung Gen 3 Lithium

Dec 18, 2024 · Eaton''s Gen 3 lithium-ion is a reliable battery backup solution for critical infrastructure needs. Eaton has unveiled its Gen 3 lithium-ion battery

Unveiling the Wonders of Cabinet Batteries: A

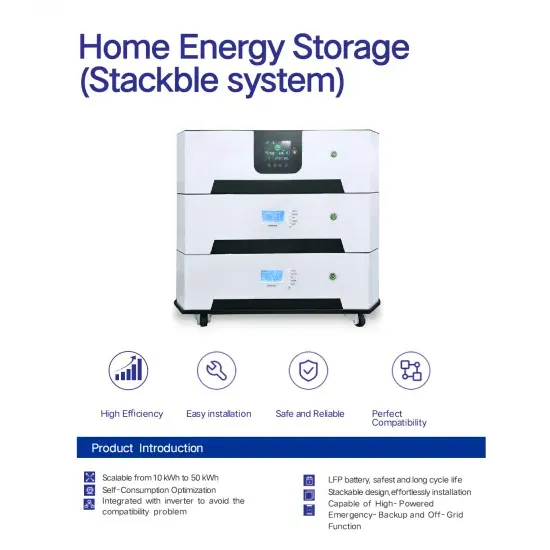

Apr 30, 2025 · What are Cabinet Batteries? Cabinet batteries, also known as battery cabinets, are self - contained units that house multiple battery cells or modules. They are designed to

How AZE Systems Manufactures BESS Battery Energy Storage Cabinets

Feb 21, 2025 · A BESS cabinet is a self-contained unit that houses battery modules, power conversion systems, and control electronics. It is designed to store electrical energy and

Exploring the World of Cabinet Batteries: Technology,

Apr 30, 2025 · Cabinet batteries are highly modular, which means that multiple battery cabinets can be easily connected together to increase the overall storage capacity. This modular design

Battery Cabinet Tech: Core Processes & Edge

With the transformation of energy structure and the increasing demand for intelligent power system, Energy Storage Battery cabinets have become important infrastructure in industrial

Understanding the Lithium

Mar 17, 2025 · When a new lithium - ion battery is produced, its internal electrochemical reactions need to be stabilized. The aging cabinet achieves this by applying a precisely regulated

Accuracy requirements for battery aging cabinets in battery

Jun 30, 2025 · The accuracy of the aging cabinet is a key indicator in the production process of battery PACK, which directly affects the accuracy and reliability of battery performance testing.

Lithium battery energy storage cabinet processing

Lithium Battery Storage & Charging Cabinets Lithium-ion battery charging cabinets, Li-Safe fire protection boxes, plastic and steel storage containers for safe transport of new or damaged

What are the energy storage cabinet processing technologies?

Sep 20, 2024 · 1. Energy storage cabinet processing technologies involve several advanced methods for efficiently storing and managing electrical energy, including 1. lithium-ion battery

Quality Energy Storage Container & Energy Storage

The electrical topology of the energy storage system is as follows OUR ADVANTAGE ·OEM/ODM professional battery manufacturing factory, installed in place, convenient and quick ·One-stop

C&D Technologies Introduces Battery Cabinets for UPS

New battery cabinet solutions provide data center engineers with seamless process to purchase high quality UPS emergency power systems. Horsham, PA – April 15, 2024.

Illustrated explanation of the battery cabinet production

The battery manufacturing process is a complex sequence of steps transforming raw materials into functional, reliable energy storage units. This guide covers the entire process, from

What are the energy storage cabinet processing technologies?

Sep 20, 2024 · Energy storage cabinet processing technologies involve several advanced methods for efficiently storing and managing electrical energy, including 1. lithium-ion battery

Understanding the Lithium

Mar 17, 2025 · For battery research institutions and R & D departments of battery - related companies, aging cabinets are used to study the long - term performance and degradation

Lithium battery energy storage cabinet processing factory

Jan 21, 2022 · The new Vertiv HPL Lithium-ion battery cabinet is available today in North America in 38 kWhcabinets. The successful completion of the UL 9540A test and its associated

Battery Cabinet Tech: Core Processes & Edge

The technical and process innovation of energy storage battery cabinets is promoting the upgrade of energy storage from single-function equipment to intelligent system solutions.

Learn More

- New Energy Battery Cabinet Power Cord Production

- New Energy Battery Cabinet Insulation Pad

- Is the new energy battery cabinet made of aluminum alloy

- Battery Cabinet New Energy

- Circuit Principle of New Energy Battery Cabinet

- New Energy Battery Cabinet Insulation

- Papua New Guinea battery storage box processing manufacturer

- New energy battery cabinet gas heating modification

- New energy battery cabinet water cooling connector

Industrial & Commercial Energy Storage Market Growth

The global industrial and commercial energy storage market is experiencing explosive growth, with demand increasing by over 250% in the past two years. Containerized energy storage solutions now account for approximately 45% of all new commercial and industrial storage deployments worldwide. North America leads with 42% market share, driven by corporate sustainability initiatives and tax incentives that reduce total project costs by 18-28%. Europe follows closely with 35% market share, where standardized industrial storage designs have cut installation timelines by 65% compared to traditional built-in-place systems. Asia-Pacific represents the fastest-growing region at 50% CAGR, with manufacturing scale reducing system prices by 20% annually. Emerging markets in Africa and Latin America are adopting industrial storage solutions for peak shaving and backup power, with typical payback periods of 2-4 years. Major commercial projects now deploy clusters of 15+ systems creating storage networks with 80+MWh capacity at costs below $270/kWh for large-scale industrial applications.

Industrial Energy System Innovations & Cost Benefits

Technological advancements are dramatically improving industrial energy storage performance while reducing costs. Next-generation battery management systems maintain optimal operating conditions with 45% less energy consumption, extending battery lifespan to 20+ years. Standardized plug-and-play designs have reduced installation costs from $85/kWh to $40/kWh since 2023. Smart integration features now allow multiple industrial systems to operate as coordinated energy networks, increasing cost savings by 30% through peak shaving and demand charge management. Safety innovations including multi-stage fire suppression and thermal runaway prevention systems have reduced insurance premiums by 35% for industrial storage projects. New modular designs enable capacity expansion through simple system additions at just $200/kWh for incremental capacity. These innovations have improved ROI significantly, with commercial and industrial projects typically achieving payback in 3-5 years depending on local electricity rates and incentive programs. Recent pricing trends show standard industrial systems (1-2MWh) starting at $330,000 and large-scale systems (3-6MWh) from $600,000, with volume discounts available for enterprise orders.