Exploring the Flow and Mass Transfer Characteristics of an

Apr 21, 2025 · To improve the flow mass transfer inside the electrodes and the efficiency of an all-iron redox flow battery, a semi-solid all-iron redox flow battery is presented experimentally. A

Flow Batteries & Renewable Energy

Magnetic drive chemical pumps are the solid choice for flow batteries, with a proven track record in flow battery applications for more than 25 years, helping meet the increasing regulatory

Practical flow battery diagnostics enabled by chemically

Jul 10, 2025 · Here, we utilize solution pH and bulk magnetic susceptibility to monitor the native minor equilibrium side reaction between water and the one-electron oxidized state of 2,2,6,6

A united voice for flow batteries

Sep 25, 2023 · The role of flow batteries Flow batteries are energy storage systems particularly well-suited for long-duration energy storage (LDES; over 4 hours) through the storage of liquid

Finish Thompson Highlights Advanced Pump Solutions for Flow Batteries

Feb 5, 2025 · One of the key advantages of Finish Thompson''s pumps is their mag-drive technology, which eliminates the need for mechanical seals. This innovative design not only

Application of magnetic pumps in new energy fields

Mar 28, 2025 · From liquid flow batteries to hydrogen energy systems, magnetic drive pumps are driving the safety and efficiency upgrades of the new energy industry. As the global demand

Process Magnetic Drive Pump Global Technical Information

May 24, 2020 · The pump design features a mechanism to withstand dry running. High magnetic power of the rare earth magnets prevents the magnet capsule from coming into contact with

Redox Flow Battery for Energy Storage

Mar 22, 2015 · Among the energy storage technologies, battery energy storage technology is considered to be most viable. In particular, a redox flow battery, which is suitable for large

Overview of Flow Batteries

Aug 4, 2024 · Understanding the fundamental behavior of conductive particles and the effect of additional additives in slurry electrodes are critical for optimizing battery performance.

The crucial role of parallel and interdigitated flow channels in

Nov 15, 2021 · Considering that parallel and interdigitated flow channels are widely employed in conventional rectangular flow battery to improve the electrolyte distribution uniformity, radial

A review of transport properties of electrolytes in redox flow batteries

Feb 1, 2025 · Redox flow battery is a competitive grid-level energy storage technique that is especially suitable for large-scale and long-duration energy storage. In redox flow batteries,

Redox Flow Battery for Energy Storage

May 22, 2001 · Among the energy storage technologies, battery energy storage technology is considered to be most viable. In particular, a redox flow battery, which is suitable for large

Ready to go, navigating the future: QEEHUA PUMP magnetic pumps

May 5, 2024 · As a leading manufacturer of chemical pumps, QEEHUA PUMP showcased magnetic pumps that serve as critical components in flow battery systems. Magnetic pumps

What Are Flow Batteries? A Beginner''s Overview

Jan 14, 2025 · Part 1. What is the flow battery? A flow battery is a type of rechargeable battery that stores energy in liquid electrolytes, distinguishing itself from conventional batteries, which

6 FAQs about [The role of the flow battery magnetic pump]

How do flow batteries work?

Flow batteries are particularly suited for grid-level electricity storage because they can be scaled up easily. They produce energy by pumping liquid electrolytes through a cell, and increasing their capacity is simply a matter of increasing the size of the storage tanks for the electrolytes.

How does a magnetic pump work?

The drive magnet and the inner magnet are separated by a housing, resulting in less sealing. Driving the pump with the induced magnetic field helps in avoiding fluid leakage and in performance optimization. Content may be subject to copyright. The nature of fluids to be mixed determines the equipment used.

What is a magnetic drive pump?

(PDF) Magnetic drive pumps. Current state and overview Magnetic drive pumps. Current state and overview The paper presents the current stage of constructive-technological and functional researches on magnetic drive pumps. This type of pump is provided with a closed system for driving and pumping the fluid.

How does a pump work?

The studied pumps use a construction system containing an external drive magnet and an internal magnet that is connected to an impeller that moves the fluid. The drive magnet and the inner magnet are separated by a housing, resulting in less sealing.

What is a fluid pump used for?

These pumps drive a specific fluid characterized by: flow, pressure, viscosity, presence of particles, for applications like: fuel transfer, injection and/or mixing, recirculation in a circuit, dosing of substances with medical applications, mixing of additives or chemicals, printing on textiles and ceramic tiles, etc.

How does a hydraulic pump work?

This type of pump is provided with a closed system for driving and pumping the fluid. It is envisaged that the rotation of the motor shaft is done by induction of a magnetic field without external drive from an electric motor, as in the case of classical hydraulic pumps.

Learn More

- Lisbon Aluminum Acid Energy Storage Battery Magnetic Pump

- Zhongya Energy Storage Battery Magnetic Pump

- Riyadh All-vanadium Liquid Flow Battery Pump

- Algeria large capacity all-vanadium flow battery electrolyte pump

- Zinc flow battery

- Flow battery manufacturing equipment price

- Sodium flow battery energy storage

- Is flow battery a new energy source

- Zinc manganese dioxide flow battery

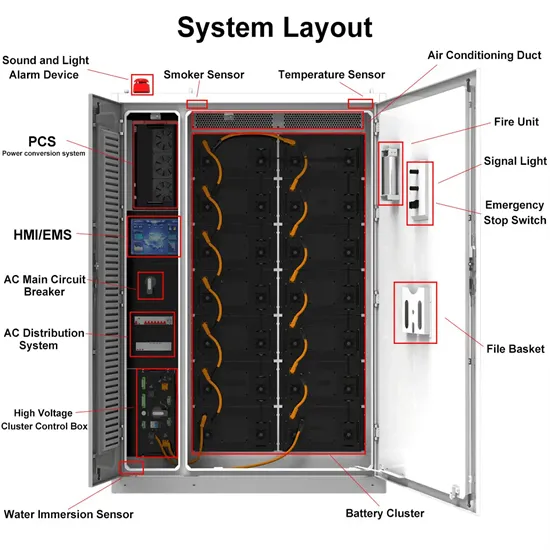

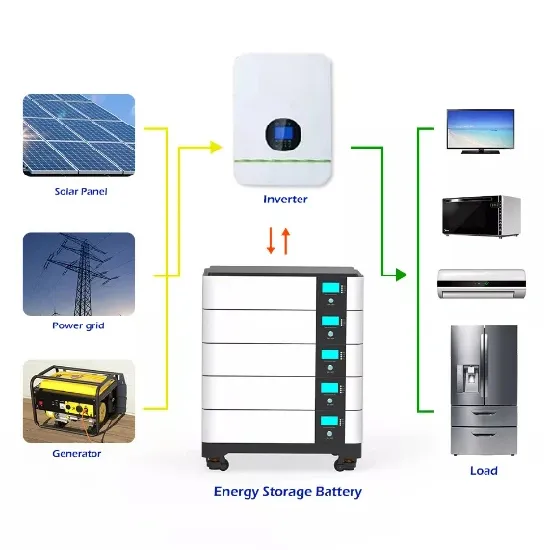

Industrial & Commercial Energy Storage Market Growth

The global industrial and commercial energy storage market is experiencing explosive growth, with demand increasing by over 250% in the past two years. Containerized energy storage solutions now account for approximately 45% of all new commercial and industrial storage deployments worldwide. North America leads with 42% market share, driven by corporate sustainability initiatives and tax incentives that reduce total project costs by 18-28%. Europe follows closely with 35% market share, where standardized industrial storage designs have cut installation timelines by 65% compared to traditional built-in-place systems. Asia-Pacific represents the fastest-growing region at 50% CAGR, with manufacturing scale reducing system prices by 20% annually. Emerging markets in Africa and Latin America are adopting industrial storage solutions for peak shaving and backup power, with typical payback periods of 2-4 years. Major commercial projects now deploy clusters of 15+ systems creating storage networks with 80+MWh capacity at costs below $270/kWh for large-scale industrial applications.

Industrial Energy System Innovations & Cost Benefits

Technological advancements are dramatically improving industrial energy storage performance while reducing costs. Next-generation battery management systems maintain optimal operating conditions with 45% less energy consumption, extending battery lifespan to 20+ years. Standardized plug-and-play designs have reduced installation costs from $85/kWh to $40/kWh since 2023. Smart integration features now allow multiple industrial systems to operate as coordinated energy networks, increasing cost savings by 30% through peak shaving and demand charge management. Safety innovations including multi-stage fire suppression and thermal runaway prevention systems have reduced insurance premiums by 35% for industrial storage projects. New modular designs enable capacity expansion through simple system additions at just $200/kWh for incremental capacity. These innovations have improved ROI significantly, with commercial and industrial projects typically achieving payback in 3-5 years depending on local electricity rates and incentive programs. Recent pricing trends show standard industrial systems (1-2MWh) starting at $330,000 and large-scale systems (3-6MWh) from $600,000, with volume discounts available for enterprise orders.