Energy Storage Center Factory Operation: Powering the

May 3, 2020 · Here''s a fun fact: The average energy storage factory now uses more robotics than a sci-fi movie set. ABB recently reported that their automated electrode production lines can

5 Energy Storage Solutions for Factories Using Solar Power

Jul 27, 2025 · Key Takeaway Choosing the right energy storage solution for your factory is crucial to maximizing the benefits of solar energy. By investing in the right storage system, you can

The Nuts and Bolts of Energy Storage Company Factory

The 3-Legged Stool of Factory Operations [8] Recent data from China''s Qinghai province shows smart factories achieving 92% OEE (Overall Equipment Effectiveness) – here''s how:

How Factory Energy Storage Works: Powering Industries

Mar 21, 2024 · The Secret Sauce: How Factory Energy Storage Actually Works Your factory is a sprinter in the 100m dash of production. Traditional energy systems are like trying to run while

What are the energy storage equipment in the factory?

Mar 30, 2024 · Energy management in contemporary manufacturing is evolving rapidly, and energy storage equipment plays a pivotal role in this transformation. Factories and production

Energy Storage Is the Lifeline Your Factory Needs-Blog

Aug 8, 2025 · Facing power outages this summer? Discover how AlphaESS commercial energy storage systems keep your factory running during grid failures, cut energy costs, and support

How can power-rationed factories cope with energy storage?

Feb 7, 2024 · 1. POWER RATIONING STRATEGIES: Power-rationed factories grapple with energy constraints, necessitating innovative energy storage solutions, and adopting efficient

Can the Factory Be Equipped with Energy Storage? Here''s

Dec 6, 2020 · With 72% of manufacturers now prioritizing energy resilience [5], factories equipped with storage aren''t just surviving power chaos – they''re thriving. Peak shaving: Buy low (off

Small Factory Energy Storage Projects: Powering Efficiency in

May 25, 2024 · Let''s be real – running a small factory today feels like juggling chainsaws while riding a unicycle. Between volatile energy prices and sustainability pressures, manufacturers

Can the Factory Be Equipped with Energy Storage? Here''s

Dec 6, 2020 · Why Factories Are Jumping on the Energy Storage Bandwagon Imagine this: your factory humming along smoothly during a blackout, or slashing electricity bills by "time

Energy Storage Systems for Industry: Efficiency & Resilience

1 day ago · Learn how on-site industrial energy storage systems enhance productivity, protect operations, and deliver long-term competitive advantage.

Why Energy Storage Factories Are Powering the Future (And

Jun 1, 2022 · Whether you''re looking to stabilize your factory''s power supply or become the energy storage equivalent of a Swiss Army knife, one thing''s clear: energy storage factories

Industrial Energy Storage: Powering Factories and Industries

Mar 30, 2025 · Industrial energy storage is essential for manufacturers. This article reviews various systems, such as lithium-ion batteries, flywheels, and thermal energy storage,

Top 10 Applications of Industrial and Commercial Energy Storage

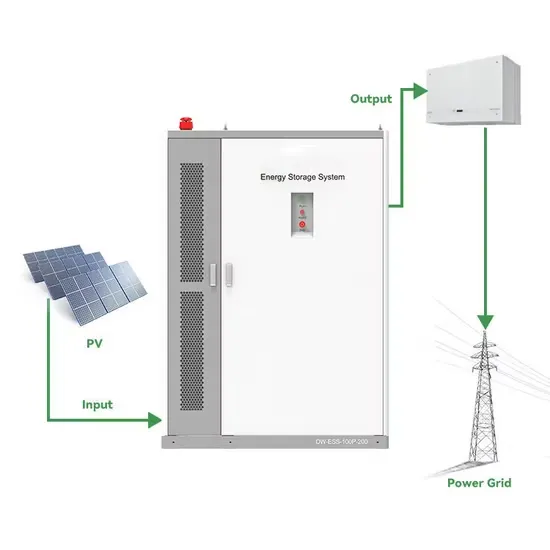

Jan 26, 2025 · Deploying energy storage systems in industrial microgrids can effectively store and dispatch the power generated by distributed power sources (such as photovoltaic and wind

How Energy Storage In Manufacturing Enhances Energy

Mar 5, 2025 · How energy storage is key to unlocking energy resilience in manufacturing: helping to overcome capacity caps, reduce costs, and achieve sustainability goals.

6 FAQs about [Can energy storage drive factory equipment ]

What are energy storage systems?

Energy storage systems allow energy consumption to be separated in time from the production of energy, whether it be electrical or thermal energy. The storing of electricity typically occurs in chemical (e.g., lead acid batteries or lithium-ion batteries, to name just two of the best known) or mechanical means (e.g., pumped hydro storage).

Are battery electricity storage systems a good investment?

Battery electricity storage systems offer enormous deployment and cost-reduction potential, according to the IRENA study on Electricity storage and renewables: Costs and markets to 2030.

Why is electricity storage important?

More directly, electricity storage makes possible a transport sector dominated by electric vehicles; enables effective, 24-hour off-grid solar home systems; and supports 100% renewable mini-grids. et, electricity markets frequently fail to account properly for the system value of storage.

What is thermal energy storage?

Thermal energy storage (TES) can help to integrate high shares of renewable energy in power generation, industry, and buildings sectors. TES technologies include molten-salt storage and solid-state and liquid air variants.

What is the electricity storage valuation framework?

The Electricity Storage Valuation Framework report proposes a five-phase method to assess the value of storage and create viable investment conditions to guide storage deployment for the effective integration of solar and wind power. Battery electricity storage is a key technology in the world’s transition to a sustainable energy system.

How do electricity markets assess the value of storage?

et, electricity markets frequently fail to account properly for the system value of storage. The Electricity Storage Valuation Framework report proposes a five-phase method to assess the value of storage and create viable investment conditions to guide storage deployment for the effective integration of solar and wind power.

Learn More

- Belize Energy Storage Equipment Factory

- BESS solution for factory energy storage equipment

- Gaborone DC Energy Storage Equipment Factory

- Factory Energy Storage Equipment Project

- Factory Energy Storage Equipment BESS

- Honduras Energy Storage Equipment Wholesale

- Bulgarian industrial energy storage equipment manufacturer

- Senegal lithium energy storage power supply custom-made factory

- Dubai container energy storage equipment

Industrial & Commercial Energy Storage Market Growth

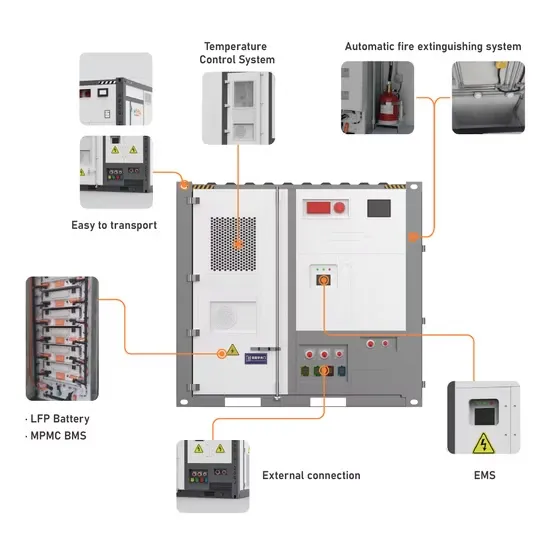

The global industrial and commercial energy storage market is experiencing explosive growth, with demand increasing by over 250% in the past two years. Containerized energy storage solutions now account for approximately 45% of all new commercial and industrial storage deployments worldwide. North America leads with 42% market share, driven by corporate sustainability initiatives and tax incentives that reduce total project costs by 18-28%. Europe follows closely with 35% market share, where standardized industrial storage designs have cut installation timelines by 65% compared to traditional built-in-place systems. Asia-Pacific represents the fastest-growing region at 50% CAGR, with manufacturing scale reducing system prices by 20% annually. Emerging markets in Africa and Latin America are adopting industrial storage solutions for peak shaving and backup power, with typical payback periods of 2-4 years. Major commercial projects now deploy clusters of 15+ systems creating storage networks with 80+MWh capacity at costs below $270/kWh for large-scale industrial applications.

Industrial Energy System Innovations & Cost Benefits

Technological advancements are dramatically improving industrial energy storage performance while reducing costs. Next-generation battery management systems maintain optimal operating conditions with 45% less energy consumption, extending battery lifespan to 20+ years. Standardized plug-and-play designs have reduced installation costs from $85/kWh to $40/kWh since 2023. Smart integration features now allow multiple industrial systems to operate as coordinated energy networks, increasing cost savings by 30% through peak shaving and demand charge management. Safety innovations including multi-stage fire suppression and thermal runaway prevention systems have reduced insurance premiums by 35% for industrial storage projects. New modular designs enable capacity expansion through simple system additions at just $200/kWh for incremental capacity. These innovations have improved ROI significantly, with commercial and industrial projects typically achieving payback in 3-5 years depending on local electricity rates and incentive programs. Recent pricing trends show standard industrial systems (1-2MWh) starting at $330,000 and large-scale systems (3-6MWh) from $600,000, with volume discounts available for enterprise orders.