Utility-scale battery energy storage system (BESS)

Mar 21, 2024 · Introduction Reference Architecture for utility-scale battery energy storage system (BESS) This documentation provides a Reference Architecture for power distribution and

China Focus: Tesla''s new mega factory project in

Dec 22, 2023 · The new project is scheduled to break ground in the first quarter of 2024 and start production in the fourth quarter. The factory will initially produce

How much does a factory energy storage system cost?

May 20, 2024 · The cost of a factory energy storage system typically involves several factors that can significantly affect the overall price. These include: 1. Type of technology used in the

Tesla''s energy storage super factory in Shanghai begins trial

Tesla China announced on Tuesday that the Tesla Shanghai Energy Storage Super Factory project successfully passed completion inspection on Dec. 27, taking only seven months from

Factory Energy Storage Equipment Projects: Powering

Jun 19, 2019 · Early adopters of factory energy storage equipment projects are already: As microgrids and AI optimization enter the chat, factory storage is becoming the ultimate

What are the factory energy storage equipment? | NenPower

Feb 24, 2024 · What are the factory energy storage equipment? 1. Definition of Factory Energy Storage Equipment: Factory energy storage equipment refers to various systems and

What does the factory energy storage project include?

May 1, 2024 · 1, The factory energy storage project encompasses various components, primarily focusing on energy capture, storage, and management systems, 2, It integrates renewable

Utility Battery Energy Storage System (BESS) Handbook

Oct 7, 2024 · Research Overview Primary Audience Utility project managers and teams developing, planning, or considering battery energy storage system (BESS) projects.

Moss Landing: World''s biggest battery storage

Aug 2, 2023 · Battery racks provided by LG Energy Solution sit in former turbine halls at Moss Landing Energy Storage Facility, California. Image: LG Energy

Tesla Energy Storage Project Lands in Shanghai: Boosting

Explore Tesla''s strategic decision to launch a new Megapack factory in Shanghai, leveraging China''s manufacturing and supply chain advantages. Learn how this move boosts global

3 FAQs about [Factory Energy Storage Equipment Project]

What is an energy storage project?

An energy storage project is a cluster of battery banks (or modules) that are connected to the electrical grid. These battery banks are roughly the same size as a shipping container. These are also called Battery Energy Storage Systems (BESS), or grid-scale/utility-scale energy storage or battery storage systems.

Where are the energy storage projects being built?

The energy storage projects will be located at three existing SCE power substations: 225 MW at Springvale Substation in Big Creek-Ventura, 200 MW at Hinson Substation in the Los Angeles Basin, and 112.5 MW at Etiwanda Substation in the Los Angeles Basin.

What is the Tesla megafactory?

The Megafactory is the first of its kind that Tesla has built outside the United States. At its launch ceremony in May, Tesla signed a deal with Shanghai Lingang Economic Development (Group) Co Ltd, securing the first batch of orders for its Megapacks in China.

Learn More

- Conakry Zhongshi Metallurgical Energy Storage Equipment Project

- Alofi Energy Storage Equipment Project

- Greece EK SOLAR Energy Storage Equipment Factory

- Gaborone DC Energy Storage Equipment Factory

- Huawei Sweden Energy Storage Equipment Project

- BESS solution for factory energy storage equipment

- Electrochemical Energy Storage Project Power Distribution

- Latvia 300mw energy storage project

- What is a photovoltaic project energy storage station

Industrial & Commercial Energy Storage Market Growth

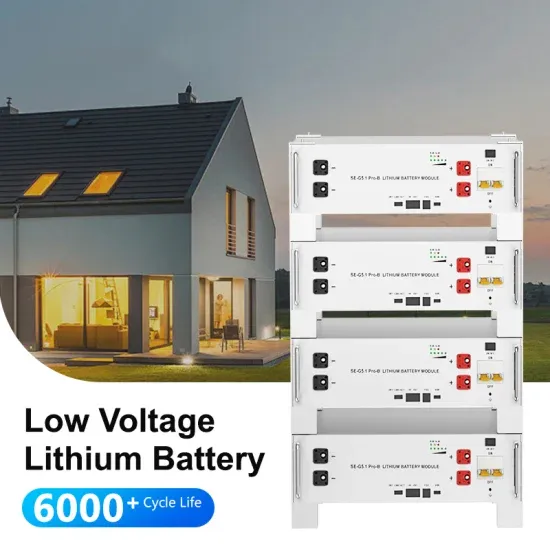

The global industrial and commercial energy storage market is experiencing explosive growth, with demand increasing by over 250% in the past two years. Containerized energy storage solutions now account for approximately 45% of all new commercial and industrial storage deployments worldwide. North America leads with 42% market share, driven by corporate sustainability initiatives and tax incentives that reduce total project costs by 18-28%. Europe follows closely with 35% market share, where standardized industrial storage designs have cut installation timelines by 65% compared to traditional built-in-place systems. Asia-Pacific represents the fastest-growing region at 50% CAGR, with manufacturing scale reducing system prices by 20% annually. Emerging markets in Africa and Latin America are adopting industrial storage solutions for peak shaving and backup power, with typical payback periods of 2-4 years. Major commercial projects now deploy clusters of 15+ systems creating storage networks with 80+MWh capacity at costs below $270/kWh for large-scale industrial applications.

Industrial Energy System Innovations & Cost Benefits

Technological advancements are dramatically improving industrial energy storage performance while reducing costs. Next-generation battery management systems maintain optimal operating conditions with 45% less energy consumption, extending battery lifespan to 20+ years. Standardized plug-and-play designs have reduced installation costs from $85/kWh to $40/kWh since 2023. Smart integration features now allow multiple industrial systems to operate as coordinated energy networks, increasing cost savings by 30% through peak shaving and demand charge management. Safety innovations including multi-stage fire suppression and thermal runaway prevention systems have reduced insurance premiums by 35% for industrial storage projects. New modular designs enable capacity expansion through simple system additions at just $200/kWh for incremental capacity. These innovations have improved ROI significantly, with commercial and industrial projects typically achieving payback in 3-5 years depending on local electricity rates and incentive programs. Recent pricing trends show standard industrial systems (1-2MWh) starting at $330,000 and large-scale systems (3-6MWh) from $600,000, with volume discounts available for enterprise orders.