What is the difference between a double-sided double-glass

May 22, 2025 · The difference between double-sided double-glass n-type monocrystalline solar photovoltaic module and ordinary components is reflected in multiple dimensions, from core

Double Glass PV Module Installation Introduction

Sep 8, 2018 · Front and back glass could protect solar cells. The module which the glass is broken must be replaced immediately. In ordinary outdoor environment, current and voltage

Double-glass PV modules with silicone encapsulation

May 21, 2024 · ABSTRACT Double-glass PV modules are emerging as a technology which can deliver excellent performance and excellent durability at a competitive cost. In this paper a

Something About Double-glass PV Modules, Transparent

Feb 17, 2025 · With the rationalization of the price of 2.0mm glass, framed 2.0mm double-glass modules will achieve the same manufacturing cost as ordinary single-glass modules or

A kind of double-glass photovoltaic module window and its

Description technical field [0001] The invention relates to the field of solar photovoltaic technology, in particular to a double-glass photovoltaic module window and a manufacturing method

The Performance of Double Glass Photovoltaic Modules

Sep 1, 2017 · Canadian Solar''s Dymond double glass module passed 3 times IEC standard test and IEC 61730-2:2016 multiple combination of limit test and obtained VDE report, which fully

INSTRUCTIONS FOR PREPARATION OF PAPERS

3 days ago · The double glass module design offers not only much higher reliability and longer durability but also significant Balance of System cost savings by eliminating the aluminum

Difference between double glass photovoltaic module and ordinary module

1. The warranty of ordinary modules is 25 years and that of double glass photovoltaic modules is 30 years. 2. The power generation with higher life cycle is 21% higher than that of ordinary

双玻光伏组件介绍

Oct 31, 2017 · About double glazing panel 交大光谷双玻光伏组件,是指由两片玻璃和太阳能电池片组成复合层,电池片之间由导线串、并联汇集到引线端所形

有道翻译_文本、文档、、在线即时翻译

Jan 17, 2025 · 有道翻译提供即时免费的中文、英语、日语、韩语、法语、德语、俄语、西班牙语、葡萄牙语、越南语、印尼语、意大利语、荷兰语、泰语全文

The Difference Between Bifacial Module and

Sep 4, 2023 · Bifacial solar modules and double glass bifacial solar modules are both types of solar panels designed to capture sunlight from both sides (front

The Difference Between the Double Glass Photovoltaic Modules

About 7%, double glass component is zero. 5%. 6, double glass components of fire rating by ordinary silicon components C level upgrade to A level, to make it more suitable for residential

What are the differences between single-glass

Oct 22, 2020 · Single-glass Solar Module: As the first layer of materials in the solar module structure, tempered glass can effectively protect the panel and

THE DIFFERENCE BETWEEN DOUBLE GLASS PHOTOVOLTAIC MODULES AND ORDINARY

The difference between modules and photovoltaic panels Decided to purchase solar panels but cannot find the answer to what is solar module type suits your requirements. Here is the list of

Installation instructions for framed glass-glass PV modules

Oct 13, 2021 · The module with broken glass (risk of electric shock and fire) should be replaced immediately. In ordinary outdoor environment, the current and voltage generated by the PV

What is a double-sided double-glass module?

Mar 7, 2023 · Function level: longer life cycle PERC double-glass double-sided modules integrate the anti-PID characteristics of double-glass modules, and have the advantages of being

Introduction of photovoltaic glass

Introduction of photovoltaic glassPhotovoltaic glass is the glass used for photovoltaic modules, it is been widely used as the cover glass of ordinary photovoltaic modules, the cover plate and

What is a double-sided double-glass photovoltaic module?

Jul 7, 2022 · PERC double-glass double-sided modules integrate the anti-PID characteristics of double-glass modules, and have the advantages of high efficiency and low-cost systems

The Performance of Double Glass Photovoltaic Modules

Sep 1, 2017 · In recent years, with the rapid development of the photovoltaic industry, double glass module as a high reliability and high weather resistance product is favored by many PV

Double Glass PV Module Installation Introduction

May 5, 2019 · Front and back glass could protect solar cells. The module which the glass is broken must be replaced immediately. In ordinary outdoor environment, current and voltage

How are photovoltaic double-glass modules installed?

Jul 1, 2022 · The early double-glass modules used standard photovoltaic glass before and after, so they were heavy and inconvenient to handle. At the same time, since the power loss

How are photovoltaic double-glass modules installed?

Nov 12, 2022 · Photovoltaic double-glass modules refer to photovoltaic cell modules formed by two pieces of tempered glass, EVA film and solar cell silicon wafers through a laminator.

6 FAQs about [Double glass modules and ordinary modules]

Are double-glass solar modules reactive or non-reactive?

Furthermore, comparing to plastic backsheets (the back material of single-glass solar module) which are reactive, glass is non-reactive. This means that the whole structure of Raytech double-glass solar modules (two layers of glass and one layer of solar cells in the middle) are highly resistant to chemical reactions such as corrosion as a whole.

What is a double glass module?

Double glass module contains two sheets of glass, whereby the back sheet is made of heat strengthened (semi-tempered) glass to substitute the traditional polymer backsheet. With * Corresponding author. Tel.: +86 13776101913; fax: +86 51268961413.

How reliable is Canadian Solar's Dymond double glass module?

Canadian Solar’s Dymond double glass module passed 3 times IEC standard test and IEC 61730-2:2016 multiple combination of limit test and obtained VDE report, which fully indicate high lifetime and high reliability of this double glass module. This paper presents a detailed reliability study of Canadian Solar’s Dymond double glass module.

What is double glass photovoltaic module?

Preface To further extend the s rvice life of photovoltaic modules, double glass photovoltaic module has cently been develop d and st died in the PV community. Double lass module contains two sheets of glass, whereby the back sheet is made of heat strengthened (semi-tempered) glass to substitute the traditional polymer backsheet.

What is the difference between Raytech double glass solar modules?

Whereas for Raytech double-glass solar modules, with the increased strength brought by two layers of glass, a lot less deformation will happen in the solar cells, the possibility of microcracks formed on the solar cells will decrease significantly.

What is tempered glass solar module?

Single-glass Solar Module: As the first layer of materials in the solar module structure, tempered glass can effectively protect the panel and solar cells against physical stress, snow, wind, dust and moisture etc, at the same time guaranteeing that the sunlight can go in. The backside is generally protected by an opaque sheet called the backsheet.

Learn More

- Application of solar double glass modules

- Tirana double glass photovoltaic modules

- Mexico double glass modules

- History of Double Glass Modules

- Oslo double glass photovoltaic module price

- 9BB high efficiency photovoltaic double glass module

- Marshall Islands double glass photovoltaic curtain wall installation

- Color PVB high efficiency double glass components

- Georgia photovoltaic double glass module manufacturer

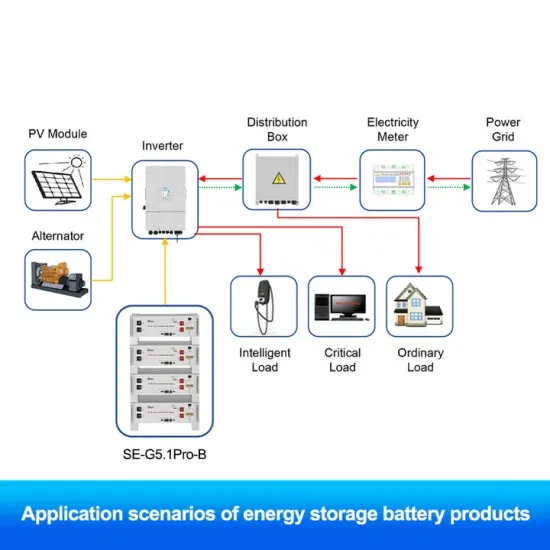

Industrial & Commercial Energy Storage Market Growth

The global industrial and commercial energy storage market is experiencing explosive growth, with demand increasing by over 250% in the past two years. Containerized energy storage solutions now account for approximately 45% of all new commercial and industrial storage deployments worldwide. North America leads with 42% market share, driven by corporate sustainability initiatives and tax incentives that reduce total project costs by 18-28%. Europe follows closely with 35% market share, where standardized industrial storage designs have cut installation timelines by 65% compared to traditional built-in-place systems. Asia-Pacific represents the fastest-growing region at 50% CAGR, with manufacturing scale reducing system prices by 20% annually. Emerging markets in Africa and Latin America are adopting industrial storage solutions for peak shaving and backup power, with typical payback periods of 2-4 years. Major commercial projects now deploy clusters of 15+ systems creating storage networks with 80+MWh capacity at costs below $270/kWh for large-scale industrial applications.

Industrial Energy System Innovations & Cost Benefits

Technological advancements are dramatically improving industrial energy storage performance while reducing costs. Next-generation battery management systems maintain optimal operating conditions with 45% less energy consumption, extending battery lifespan to 20+ years. Standardized plug-and-play designs have reduced installation costs from $85/kWh to $40/kWh since 2023. Smart integration features now allow multiple industrial systems to operate as coordinated energy networks, increasing cost savings by 30% through peak shaving and demand charge management. Safety innovations including multi-stage fire suppression and thermal runaway prevention systems have reduced insurance premiums by 35% for industrial storage projects. New modular designs enable capacity expansion through simple system additions at just $200/kWh for incremental capacity. These innovations have improved ROI significantly, with commercial and industrial projects typically achieving payback in 3-5 years depending on local electricity rates and incentive programs. Recent pricing trends show standard industrial systems (1-2MWh) starting at $330,000 and large-scale systems (3-6MWh) from $600,000, with volume discounts available for enterprise orders.