Double-glass PV modules with silicone encapsulation

May 21, 2024 · Introduction Recently several double-glass (also called glass–glass or dual-glass modules) c-Si PV modules have been launched on the market, many of them by major PV

What Are the Advantages of Using Double-Glass Modules in

Feb 10, 2025 · What Are the Advantages of Using Double-Glass Modules in Solar Monitoring Equipment? Solar monitoring equipment requires a reliable and long-lasting power source,

Double Glass PV Modules Future-proof Strategies: Trends,

Apr 21, 2025 · The global double glass PV module market is experiencing robust growth, projected to reach $22,060 million in 2025 and maintain a Compound Annual Growth Rate

Experimental investigation on the combustion performance

Jun 15, 2025 · Under similar glass material conditions, double-glazed modules exhibited superior combustion performance compared to their single-glass counterparts. Therefore, locations

What are the advantages of dual-glass Dualsun modules?

Aug 18, 2025 · The thickness of the front glass generally used for this type of structure is 3.2 mm. Dual-glass type modules (also called double glass or glass-glass) are made up of two glass

INSTRUCTIONS FOR PREPARATION OF PAPERS

3 days ago · The double glass module design offers not only much higher reliability and longer durability but also significant Balance of System cost savings by eliminating the aluminum

Double Glass Module Photovoltaic Glass Market

The shift toward double glass modules in the photovoltaic industry is driven by their **superior durability, higher energy yield, and alignment with sustainability goals**. Unlike traditional

Reducing the temperature of monofacial double-glass photovoltaic module

Apr 1, 2025 · Few studies have shown the in-plane thermal conductivity influence on the temperature of PV modules. In this paper, Al foil with high thermal conductivity was introduced

High performance double-glass bifacial PV modules

Oct 5, 2016 · Double-glass structure shows a loss of ~ 1.30% compare to the glass/backsheet structure under STC measurements. J. P. Singh, et al. "Comparison of Glass/glass and

Double Glass Module Photovoltaic Glass Unlocking Growth

Mar 29, 2025 · The double-glass module photovoltaic (PV) glass market is experiencing robust growth, driven by increasing demand for higher efficiency and durability in solar energy

PANDA Double-Glass Module Series_Australia-Yingli Solar

Adoption of n-Mono technology to meet high-end requirements Excellent power generation, excellent reliability, and high-cost performance: Yingli Solar''s PANDA series of modules use

Emerging Double Glass PV Modules Trends and Opportunities

Apr 4, 2025 · The global double glass PV module market is experiencing robust growth, driven by increasing demand for high-efficiency and durable solar energy solutions. The market''s

Single-glass versus double-glass: a deep dive

Oct 2, 2024 · There has been a noteable shift from the initial single-facial single-glass modules to bifacial double-glass modules. Double-glass modules, with

What is photovoltaic double glass panel technology

What is photovoltaic double glass panel technology Glass-glass module structures (Glass Glass or Double Glass) is a technology that uses a glass layer on the back of the modules instead of

6 FAQs about [History of Double Glass Modules]

What is a double glass module?

Double glass module contains two sheets of glass, whereby the back sheet is made of heat strengthened (semi-tempered) glass to substitute the traditional polymer backsheet. With * Corresponding author. Tel.: +86 13776101913; fax: +86 51268961413.

What is double glass solar panels?

Glass-glass module structures (Dual Glass or Double Glass) is a technology that uses a glass layer on the back of the modules instead of the traditional polymer backsheet. Originally double-glass solar panels were heavy and expensive, allowing the lighter polymer backing panels to gain most of the market share.

What is the best double-glass module?

When it comes to double-glass, Trina Solar’s double-glass module is the most sought after product in the market. It was one of the first companies to promote and commercialize double-glass modules, and it has won industry-wide recognition for its high quality.

How reliable is Canadian Solar's Dymond double glass module?

Canadian Solar’s Dymond double glass module passed 3 times IEC standard test and IEC 61730-2:2016 multiple combination of limit test and obtained VDE report, which fully indicate high lifetime and high reliability of this double glass module. This paper presents a detailed reliability study of Canadian Solar’s Dymond double glass module.

What is double glass PV module?

Double glass PV module is known as the ultimate solution for the module encapsulation technique. Although double glass modules have many advantages, they are not yet widely used in photovoltaic power plants, for which one important reason is the large power loss due to the transmission of light in the cell gap region.

Why should you choose double-glass module?

Double-glass module is not subject to potential induced degradation (PID) and boasts excellent durability, low permeability, long life cycle and other superior qualities. Its many advantages have enabled it to yield impressive results in China’s Top Runner Program.

Learn More

- Tirana double glass photovoltaic modules

- Application of solar double glass modules

- Mexico double glass modules

- Which manufacturer has Panama double glass components

- Ultra-white solar glass photovoltaic modules

- Oslo double glass photovoltaic module price

- 9BB high efficiency photovoltaic double glass module

- Marshall Islands double glass photovoltaic curtain wall installation

- Georgia photovoltaic double glass module manufacturer

Industrial & Commercial Energy Storage Market Growth

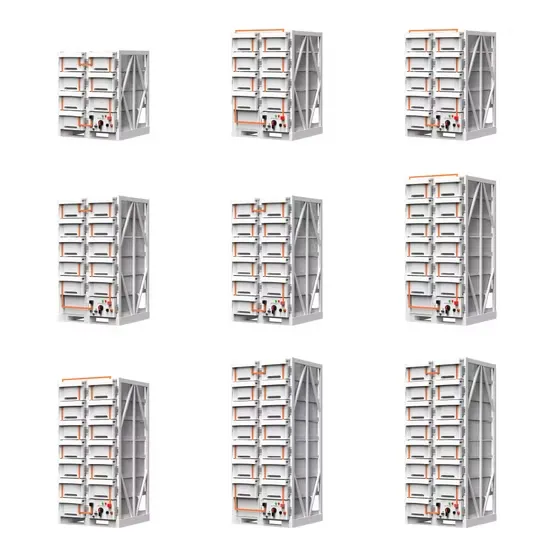

The global industrial and commercial energy storage market is experiencing explosive growth, with demand increasing by over 250% in the past two years. Containerized energy storage solutions now account for approximately 45% of all new commercial and industrial storage deployments worldwide. North America leads with 42% market share, driven by corporate sustainability initiatives and tax incentives that reduce total project costs by 18-28%. Europe follows closely with 35% market share, where standardized industrial storage designs have cut installation timelines by 65% compared to traditional built-in-place systems. Asia-Pacific represents the fastest-growing region at 50% CAGR, with manufacturing scale reducing system prices by 20% annually. Emerging markets in Africa and Latin America are adopting industrial storage solutions for peak shaving and backup power, with typical payback periods of 2-4 years. Major commercial projects now deploy clusters of 15+ systems creating storage networks with 80+MWh capacity at costs below $270/kWh for large-scale industrial applications.

Industrial Energy System Innovations & Cost Benefits

Technological advancements are dramatically improving industrial energy storage performance while reducing costs. Next-generation battery management systems maintain optimal operating conditions with 45% less energy consumption, extending battery lifespan to 20+ years. Standardized plug-and-play designs have reduced installation costs from $85/kWh to $40/kWh since 2023. Smart integration features now allow multiple industrial systems to operate as coordinated energy networks, increasing cost savings by 30% through peak shaving and demand charge management. Safety innovations including multi-stage fire suppression and thermal runaway prevention systems have reduced insurance premiums by 35% for industrial storage projects. New modular designs enable capacity expansion through simple system additions at just $200/kWh for incremental capacity. These innovations have improved ROI significantly, with commercial and industrial projects typically achieving payback in 3-5 years depending on local electricity rates and incentive programs. Recent pricing trends show standard industrial systems (1-2MWh) starting at $330,000 and large-scale systems (3-6MWh) from $600,000, with volume discounts available for enterprise orders.