Center Enamel Provides Glass-Fused-to-Steel Drinking Water

Center Enamel Provides Glass-Fused-to-Steel Drinking Water Tanks for the Panama Drinking Water Project Shijiazhuang Zhengzhong Technology Co., Ltd (Center Enamel), a global leader

Manufacturing of metallic glass components: Processes,

Aug 1, 2024 · Furthermore, it has been observed that the use of glass formers characterized by a lower crystal growth rate and sluggish crystallization kinetics holds significant advantages in

Glass Composition, Glass Types

Sep 6, 2011 · The glass compositions on this website are given in molar percent (mol%). For conversions from mol% to percent by weight (wt%) a composition converter (Excel, 28 kB) can

Double Glazing Glass Processing Machine Two Component

Jul 31, 2025 · Double Glazing Glass Processing Machine Two Component Sealant Extruded Machine Model: ST05 Application: Making Double Glazing Glass Main Features of Two

Double Glazing Glass Two Component Sealant Extruder

Jul 11, 2025 · Double Glazing Glass Two Component Sealant Extruder For Insulating Glass Machinery Model: ST05 Application: Making Double Glazing Glass Main Features of Two

Glass: Structure, Constituents and Properties | Engineering

4 days ago · 2. Structure of Glass: The glass is a random arrangement of molecules, the great majority of which are oxygen ions bounded together with the network forming ions of silicon,

Understanding the Glass Manufacturing Process:

Apr 22, 2025 · Dive into the glass manufacturing process with our comprehensive guide. Uncover the techniques and materials used to create high-quality glass

Factory Price Double Glazing Machinery Two Component

Jul 26, 2025 · Model: ST05 Application: Making Double Glazing Glass Main Features of Two Component Sealant Extruder Machine 1. The main motor of two component secondary sealing

Glass and Glass Product Manufacturing companies in Panama, Panama

Aug 1, 2025 · Find detailed information on Glass and Glass Product Manufacturing companies in Panama, Panama, including financial statements, sales and marketing contacts, top

Quartz Glass Components (Quartz Glass Component)

Aug 14, 2025 · Quartz Glass Components - You find here 15 suppliers from Germany China France Switzerland Russia and Austria. Please obtain more information on spare parts,

The Difference Between the Double Glass Photovoltaic

This characteristic makes the double glass components suitable for acid or salt fog larger areas of photovoltaic power station. 9 do not need aluminum frame, double glass components, except

Glass Composition: Key Elements, Types, Uses & Table

The composition of glass containers often involves silica (SiO 2), soda ash (sodium carbonate, Na 2 CO 3), and limestone (calcium carbonate, CaCO 3). These react during the manufacturing

Switchable smart glass is best for in Panama.Get a Free Quote...

Switchable Smart Film/Glass in Panama Smart Glass is the largest provider of aluminum and smart glasswork for commercial buildings, offering products such as curtain walls, roofs,

Industrial Valve Manufacturers In Panama, Baumer Pressure

Sahyadri Industrial Traders is one of the leading Industrial Valve Manufacturers in Panama. Whether it''s Industrial Valve or Reflex Level Gauge or Pressure Reducing Station, our

P Type Bifacial Double Glass Module DAS-DH108PA

P Type Bifacial Double Glass Module DAS-DH108PA 400W~420W Key Features High Efficiency Leading module efficiency in industry, up to 21.5% Excellent Appearance and Performance

Panama | Caribbean Wholesale Distributors | Stanscott

Our established network of Panama wholesale distribution partners is uniquely positioned to navigate the varied cultural demands of product development in the Caribbean.

Glass Components and Subassemblies | Suppliers

Explore 39 top manufacturers and suppliers of Glass Components and Subassemblies in our comprehensive photonics buyers'' guide. Custom and OEM precision glass, spinel, ceramic,

Single-glass versus double-glass: a deep dive

Oct 2, 2024 · There has been a noteable shift from the initial single-facial single-glass modules to bifacial double-glass modules. Double-glass modules, with

Double Glazed Glass Singapore | House Of Glass

2 days ago · A close alternative to Laminated Glass where two glass layers are closely and permanently sealed; double glazed glass on the contrary has a layer of air that is sandwiched

Double-glass PV modules with silicone encapsulation

May 21, 2024 · Recently several double-glass (also called glass–glass or dual-glass modules) c-Si PV modules have been launched on the market, many of them by major PV manufacturers.

(PDF) Design of additively manufactured glass components for glass

Feb 7, 2025 · This paper presents and summarizes the results of the preliminary research regarding additive manufacturing of glass components for joining methods for flat glass

Double Glazing Components | Products | FG Trading (Pty) Ltd

Our double glazing range comprises all of the components required for the manufacture of dual-sealed and single-sealed insulated glass units including rigid and flexible spacers, desiccant,

Components of double glazed windows

Dec 20, 2017 · What are the components of a double glazed window? What should we pay attention to when checking the quality of such a window? These are questions to consider

6 FAQs about [Which manufacturer has Panama double glass components ]

What is a double glass c-Si PV module?

Recently several double-glass (also called glass–glass or dual-glass modules) c-Si PV modules have been launched on the market, many of them by major PV manufacturers. These modules use a sheet of tempered glass at the rear of the module instead of the conventional polymer-based backsheet. There are several reasons why this structure is appealing.

Who makes insulated glass processing machinery?

As a glass machinery manufacturer, we devote ourselves to products quality. Our advanced technology, high quality products and reliable service bring insulated glass processors much convenience. Hanjiang specializes the manufacturing of IG-insulated glass processing machinery.

Are double-glass PV modules durable?

Double-glass PV modules are emerging as a technology which can deliver excellent performance and excellent durability at a competitive cost. In this paper a glass–glass module technology that uses liquid silicone encapsulation is described. The combination of the glass–glass structure and silicone is shown to lead to exceptional durability.

Who is Hanjiang glass processing company?

HANJIANG Provide extremally convenience to glass processors with advanced technology, high-quality products and prompt service. Hanjiang is manufacture of automatic IG production line, double glass processing equipment for insulated glass and double glass.

What is glass–glass module technology?

In this paper a glass–glass module technology that uses liquid silicone encapsulation is described. The combination of the glass–glass structure and silicone is shown to lead to exceptional durability. The concept enables safe module operation at a system voltage of 1,500V, as well as innovative, low-cost module mounting through pad bonding.

What changes are incorporated in glass-glass modules?

Another major change that is also incorporated for glass-glass modules is swapping EVA for polyolefins as an encapsulant. This is due to the free radicals produced during the cross-linking lamination process of EVA. While traditional backsheets are somewhat permeable to the free radicals, the double-glass module is not.

Learn More

- Double glass components are lightweight

- Tanzania double glass photovoltaic module manufacturer

- Georgia photovoltaic double glass module manufacturer

- Australian double glass photovoltaic module manufacturer

- Which single glass photovoltaic curtain wall manufacturer is the best in Ireland

- Install double glass components

- Color PVB high efficiency double glass components

- Bandar Seri Begawan double glass photovoltaic module manufacturer

- Kathmandu Glass Photovoltaic Manufacturer

Industrial & Commercial Energy Storage Market Growth

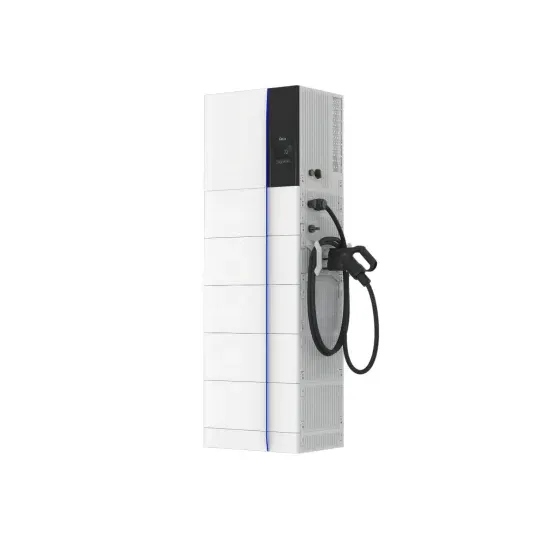

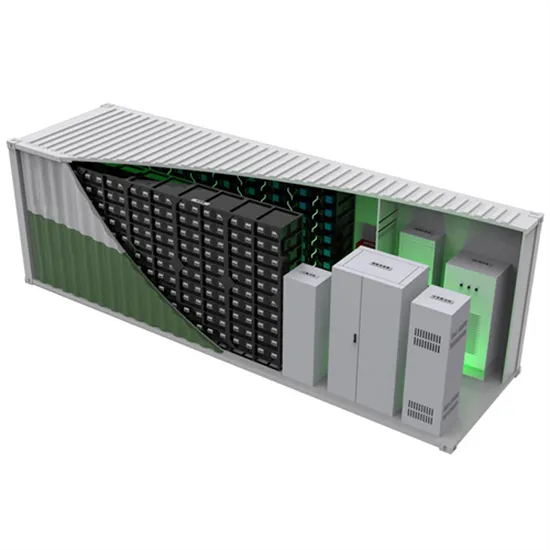

The global industrial and commercial energy storage market is experiencing explosive growth, with demand increasing by over 250% in the past two years. Containerized energy storage solutions now account for approximately 45% of all new commercial and industrial storage deployments worldwide. North America leads with 42% market share, driven by corporate sustainability initiatives and tax incentives that reduce total project costs by 18-28%. Europe follows closely with 35% market share, where standardized industrial storage designs have cut installation timelines by 65% compared to traditional built-in-place systems. Asia-Pacific represents the fastest-growing region at 50% CAGR, with manufacturing scale reducing system prices by 20% annually. Emerging markets in Africa and Latin America are adopting industrial storage solutions for peak shaving and backup power, with typical payback periods of 2-4 years. Major commercial projects now deploy clusters of 15+ systems creating storage networks with 80+MWh capacity at costs below $270/kWh for large-scale industrial applications.

Industrial Energy System Innovations & Cost Benefits

Technological advancements are dramatically improving industrial energy storage performance while reducing costs. Next-generation battery management systems maintain optimal operating conditions with 45% less energy consumption, extending battery lifespan to 20+ years. Standardized plug-and-play designs have reduced installation costs from $85/kWh to $40/kWh since 2023. Smart integration features now allow multiple industrial systems to operate as coordinated energy networks, increasing cost savings by 30% through peak shaving and demand charge management. Safety innovations including multi-stage fire suppression and thermal runaway prevention systems have reduced insurance premiums by 35% for industrial storage projects. New modular designs enable capacity expansion through simple system additions at just $200/kWh for incremental capacity. These innovations have improved ROI significantly, with commercial and industrial projects typically achieving payback in 3-5 years depending on local electricity rates and incentive programs. Recent pricing trends show standard industrial systems (1-2MWh) starting at $330,000 and large-scale systems (3-6MWh) from $600,000, with volume discounts available for enterprise orders.