Sulfur and Sulfuric Acid | SpringerLink

Nov 19, 2012 · Problems can surface. Melting or re-melting solid sulfur that has been transported by vessel requires proper knowledge and equipment. Contaminants, including sand, dirt,

Industrial sulfur separation and purification: Paving the way to energy

Apr 15, 2025 · Highlights pathways for sustainable sulfur use in energy storage. Sulfur, a by-product of industrial processes, presents a unique opportunity for advancing sustainable

Molten Sulfur Storage Tank, Loading, and Vapor Ejection

Nov 5, 2018 · These systems typically include a sulfur storage tank with associated pumps, piping and instrumentation. Load-out stations for loading the product sulfur into railcars or trucks are

Are Sulfur-Based Batteries Ready to Revolutionize Electric

Apr 16, 2025 · As industries and consumers alike seek sustainable alternatives that can power the future, sulfur-based batteries are positioned not only to complement but perhaps to redefine

Preventing or Extinguishing Molten Sulfur Tank and Pit

Sep 18, 2020 · The sulfur from the Claus unit often flows to a sulfur pit. The molten sulfur flowing into the pit (or first receiving vessel) from a Claus SRU is often assumed to contain 300 ppmw

A review of technologies and applications on versatile energy storage

Sep 1, 2021 · However, the inconsistency and intermittent nature of renewable energy will introduce operational risks to power systems, e.g., frequency and voltage stability issues [5].

Sulfur Energy Storage Could Provide Low-Cost Green

Jan 26, 2025 · The history of thermal energy storage for mobile applications dates back to the 1800s, involving a submarine that carried an insulated tank of saturated water at over 100

Sulfur Based Thermochemical Energy Storage for Solar

Solar heat energy can be stored in elemental sulfur via a three step thermochemical cycle O2 SO2 + SO2 H2O Sulfuric Acid Decomposition SO2 Disproportionation Combustion Sulfur

Materials and design strategies for next-generation energy storage

Apr 1, 2025 · Hybrid and advanced multifunctional composite materials have been extensively investigated and used in various applications over the last few years. To meet the needs of

A solar sulphur cycle to make unlimited thermal

Feb 7, 2024 · Sulfur can be stored like a pile of coal. "This cycle allows you to get energy out of the sulphur and store it in between. Why it''s in focus now is that

Manufacturing process of Liquid sulfur

2 days ago · Most sulfur recovery plants utilize one of three basic variations of the Claus process «straight-through», «split-flow» or «direct-oxidation». Uses of

How does the solar sulphur cycle contribute to

Oct 14, 2024 · When energy is needed, sulphur is burned to produce SO 2, which can drive a gas turbine for electricity generation or be converted back into H 2

IPCO_IP_Sulphur_Processing_and_Handling_08_2019

Nov 14, 2023 · We can design, integrate and commission equipment for every stage of the process, from upstream preparation, degassing and filtering of molten sulphur through a range

A solar sulphur cycle to make unlimited thermal

Feb 7, 2024 · Molten salts are currently state-of-the-art for solar thermal energy storage. But elemental sulphur has more than an order of magnitude greater

Sulfuric Acid technology

Aug 3, 2021 · Sulfur dioxide feedstock for the plant can also be produced by sulfur burning. Our portfolio covers the full process chain from sulfur handling and sulfur burning through to

Sustainable applications utilizing sulfur, a by-product from

Jul 15, 2019 · This paper reviews possible new applications in the construction, polymer, battery, thermal energy storage, and fertilizer industries, thereby providing the opportunity to more

Sulfur poised to transform the future of solar

Aug 11, 2020 · To reach their objectives, project partners have tapped into the potential of sulfur for thermochemically storing solar energy and generating

Sulfur, Energy, and Environment

Publisher Summary This chapter describes the chemical properties of sulfur and their relation to the production, use, and recovery of the element. Both basic chemistry and industrial use of

Sulfur and Sulfuric Acid | SpringerLink

Aug 2, 2017 · Melting or remelting solid sulfur that has been transported by vessel requires proper knowledge and equipment. Contaminants, including sand, dirt, rocks, and rusted metal, which

Research on Explosion Characteristics of Sulfur Dust and Risk

Jan 1, 2014 · As dust explosion is a major risk factor threating the safety of sulfur production, evaluating and controlling the hazards of sulfur dust produced in the wet process are very

Industrial sulfur separation and purification: Paving the way to energy

Apr 15, 2025 · The review emphasises the need for continued innovation in sulfur purification methods and integrating green chemistry principles to enhance sustainability. The insights

6 FAQs about [Can sulfur be used to produce energy storage equipment ]

Why is sulphur used in power plants?

Why sulphur? Sulphur can be used as fuel for gas or steam turbines in power plants. In addition, sulphur is a promising energy storage medium for solar thermal power plants. Combining these two power plant technologies is a further step towards climate-neutral electricity production.

Can sulfur be used in energy storage?

Highlights pathways for sustainable sulfur use in energy storage. Sulfur, a by-product of industrial processes, presents a unique opportunity for advancing sustainable energy storage systems, particularly in metal-sulfur batteries (MSBs) and thermal energy storage (TES) applications.

Can a sulfur-based solar energy storage system be used for solar power?

The sulfur-based technology for the storage of solar energy will be tested at the Jülich solar power tower. (Photo: DLR) Researchers of Karlsruhe Institute of Technology (KIT) and their European partners plan to develop an innovative sulfur-based storage system for solar power.

Is elemental sulphur better than molten salt for solar energy storage?

Molten salts are currently state-of-the-art for solar thermal energy storage. But elemental sulphur has more than an order of magnitude greater energy storage capacity, and is ideally suited to seasonal thermal energy storage, DLR Institute of Future Fuels research head Christian Sattler noted in a call from Germany.

Can solar power be stored in sulfur?

Researchers of Karlsruhe Institute of Technology (KIT) and their European partners plan to develop an innovative sulfur-based storage system for solar power. Large-scale chemical storage of solar power and its overnight use as a fuel are to be achieved by means of a closed sulfur-sulfuric acid cycle.

Can sulphur be stored like a pile of coal?

Sulfur can be stored like a pile of coal. “This cycle allows you to get energy out of the sulphur and store it in between. Why it’s in focus now is that we can use 100% renewable energy – concentrated solar – to heat the reaction. That’s why chemical companies now come in and are interested in demonstrating the plant.”

Learn More

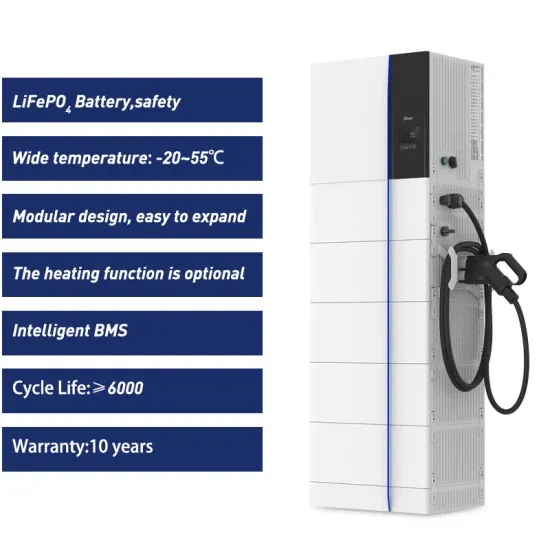

- Energy storage cabinet batteries are used to produce energy storage

- Commonly used equipment for energy storage

- Price of sodium sulfur energy storage battery

- Energy storage equipment in the power distribution room of St Petersburg Russia

- Malta energy storage power station equipment sales

- How much does energy storage equipment cost in New Zealand

- Spanish intelligent energy storage cabinet equipment

- Tanzania energy storage power station equipment

- Production of energy storage stacking equipment

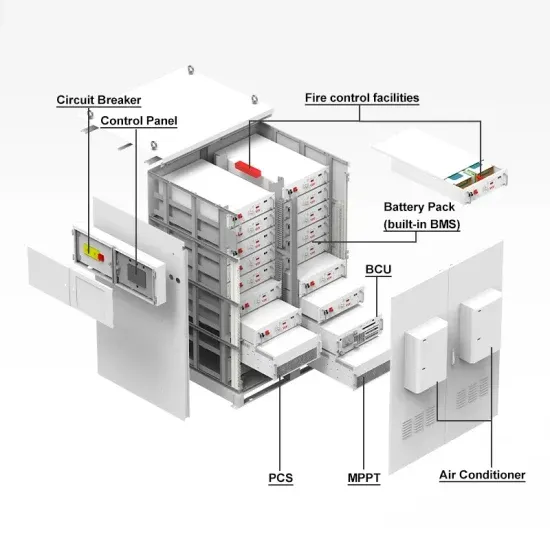

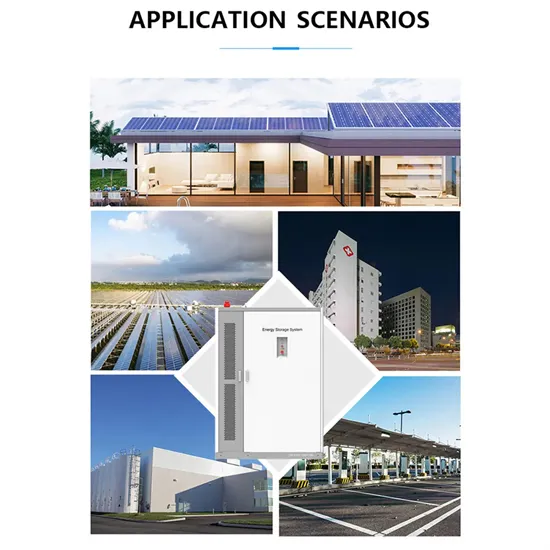

Industrial & Commercial Energy Storage Market Growth

The global industrial and commercial energy storage market is experiencing explosive growth, with demand increasing by over 250% in the past two years. Containerized energy storage solutions now account for approximately 45% of all new commercial and industrial storage deployments worldwide. North America leads with 42% market share, driven by corporate sustainability initiatives and tax incentives that reduce total project costs by 18-28%. Europe follows closely with 35% market share, where standardized industrial storage designs have cut installation timelines by 65% compared to traditional built-in-place systems. Asia-Pacific represents the fastest-growing region at 50% CAGR, with manufacturing scale reducing system prices by 20% annually. Emerging markets in Africa and Latin America are adopting industrial storage solutions for peak shaving and backup power, with typical payback periods of 2-4 years. Major commercial projects now deploy clusters of 15+ systems creating storage networks with 80+MWh capacity at costs below $270/kWh for large-scale industrial applications.

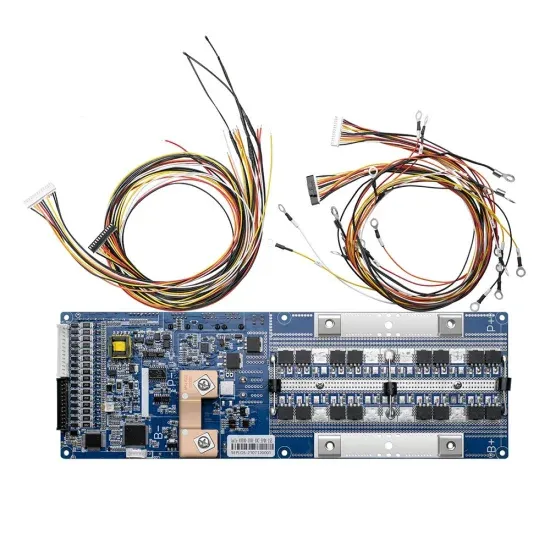

Industrial Energy System Innovations & Cost Benefits

Technological advancements are dramatically improving industrial energy storage performance while reducing costs. Next-generation battery management systems maintain optimal operating conditions with 45% less energy consumption, extending battery lifespan to 20+ years. Standardized plug-and-play designs have reduced installation costs from $85/kWh to $40/kWh since 2023. Smart integration features now allow multiple industrial systems to operate as coordinated energy networks, increasing cost savings by 30% through peak shaving and demand charge management. Safety innovations including multi-stage fire suppression and thermal runaway prevention systems have reduced insurance premiums by 35% for industrial storage projects. New modular designs enable capacity expansion through simple system additions at just $200/kWh for incremental capacity. These innovations have improved ROI significantly, with commercial and industrial projects typically achieving payback in 3-5 years depending on local electricity rates and incentive programs. Recent pricing trends show standard industrial systems (1-2MWh) starting at $330,000 and large-scale systems (3-6MWh) from $600,000, with volume discounts available for enterprise orders.