Energy storage module stacking machine

1. Suitable for stacking power and energy storage modules. 2. Single stacking platform with high rhythm. 3. The flat stack method is superior to the traditional inclined stack, with simple

Li-ion cell manufacturing: A look at processes

Jun 10, 2021 · The production of the lithium-ion battery cell consists of three main stages: electrode manufacturing, cell assembly, and cell finishing. Each of

Detailed explanation of the automatic stacking and extrusion

Sep 10, 2024 · The automatic stacking and extrusion process, as an important part in the production of battery modules, ensures that the battery cells inside the module are neatly

The role of Stacking Machines in the Production of Pouch

Oct 31, 2024 · The role of Stacking Machines in the Production of Pouch Batteries In the rapidly evolving field of battery technology, the stacking machine has emerged as a pivotal piece of

Advancing lithium-ion battery manufacturing: novel

Jun 15, 2024 · Lithium-ion batteries (LIBs) have attracted significant attention due to their considerable capacity for delivering effective energy storage. As LIBs are the predominant

Advanced New Energy High-Rate Storage Lithium Polymer

Jul 6, 2025 · A high-tech enterprise that independently develops automated production, manufacturing, and sales. Since its establishment in 2019, the company has rapidly emerged

Introduction to Stacked Energy Storage System

Jul 29, 2023 · What is a stacked energy storage system? Stacked energy storage systems utilize modular design and are divided into two specifications: parallel and series. They increase the

Energy storage battery module production stacking

What are the three parts of battery pack manufacturing process? Battery Module: Manufacturing,Assembly and Test Process Flow. In the Previous article,we saw the first three

GeB Stacked Energy Storage Solutions: Powering

GeB offers advanced stacked energy storage solutions that redefine energy management. Ideal for residential and commercial use, our innovative technology ensures reliable power storage

Customized Prismatic Cell Lithium Battery PACK Assembly

Usage Lithium-ion Battery Pack Assembly Line Process applicability for Industrial & Commercial Energy Storage System Home Battery Storage Electricity Demand Customizable Battery

Z-Shape High-Speed New Energy Arc-Type Lamination High-Rate Storage

Jul 8, 2025 · Z-Shape High-Speed New Energy Arc-Type Lamination High-Rate Storage Lithium Ion Battery Production Line Stacking Machine, Find Details and Price about Arc-Type CCD

Advanced High-Speed Lamination Stacking Equipment for Energy Storage

Jul 17, 2025 · Advanced High-Speed Lamination Stacking Equipment for Energy Storage, Find Details and Price about High-Speed Equipment Lamination Equipment from Advanced High

Prismatic Cell Stacking Extruder Machine for Energy Storage

Tianwei Saili Intelligent Equipment (dongguan) Co., Ltd. is a set of technology research, development, production and sales of new energy equipment automation equipment

Lithium Battery Pack Module Stacking and Pressing Machine

Guangdong Songke Leading Intelligent Equipment Co., Ltd. is a enery equipment intelligent manufacturer and solutor of new energy equipment integrating technology research and

A Comprehensive Guide to Choosing the Right Battery Stacking

Apr 11, 2025 · In the lithium battery manufacturing industry, battery stacking machines have become critical equipment for enhancing production efficiency and ensuring product quality. As

(PDF) Dry Stacking of Filtered Tailings for Large

Nov 16, 2023 · Dry Stacking of Filtered Tailings for Large-Scale Production Rates over 100,000 Metric Tons per Day: Envisioning the Sustainable Future of Mine

High-Precision Winding & Stacking Machines for Lithium

The winding machine and stacking machine are key pieces of equipment in lithium battery cell production. They are used to wind or stack cathode, anode, and separator materials in a

6 FAQs about [Production of energy storage stacking equipment]

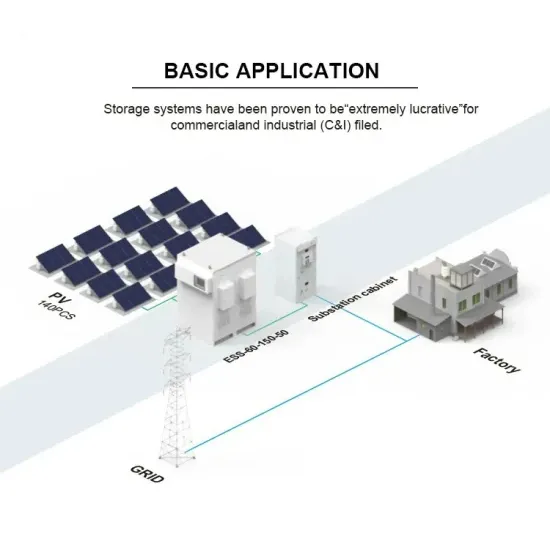

What are the applications of energy storage system?

The energy storage system can achieve applications such as solar energy storage integration, energy transfer, primary frequency regulation, secondary frequency regulation, reactive power support, short-circuit capacity, black start, virtual inertia, damping, etc. in conjunction with photovoltaic power generation.

What is a battery stack?

In this comprehensive guide, we delve into the intricacies of battery stacks, explore their varied applications, and uncover the secrets to harnessing custom stacks for tailored project needs. Exploring the Anatomy: At its core, a battery stack comprises multiple individual battery cells arranged in series or parallel configurations.

What staking process is adopted for svolt products?

Advanced staking process is adopted for SVOLT products and all series products have undergone penetration test to ensure safety. Specialized products for large-capacity electric energy storage are linked with photovoltaic, thermal power, wind power, grid dispatch and other systems through energy management systems.

What is energy storage & how does it work?

In the event of a power outage or sudden malfunction in the power grid, household energy storage can be put into standby mode to ensure basic electricity consumption. Energy replenishment can be achieved during peak electricity consumption to supplement insufficient power supply in the power grid and avoid grid overload and faults.

Which energy storage series products have full-stack coverage?

The energy storage series products of SVOLT achieved full-category coverage, providing a full-stack solution for cells, PACK, systems, and intelligent applications. Advanced staking process is adopted for SVOLT products and all series products have undergone penetration test to ensure safety.

How does a battery stack affect performance?

Each cell contributes to the overall voltage and capacity of the stack, with the arrangement determining the stack’s performance characteristics. Optimizing Performance: Within a battery stack, factors like cell chemistry, arrangement, and thermal management play pivotal roles in optimizing performance.

Learn More

- Energy storage cabinet battery production and assembly equipment

- Croatian energy storage equipment production company

- Japan Photovoltaic Energy Storage Equipment Production

- Container energy storage cabinet production equipment manufacturers

- Monaco energy storage module equipment production

- Spanish intelligent energy storage cabinet equipment

- Albanian coal-to-electricity energy storage equipment manufacturer

- Honduras lithium battery portable energy storage equipment

- How much does energy storage equipment cost in New Zealand

Industrial & Commercial Energy Storage Market Growth

The global industrial and commercial energy storage market is experiencing explosive growth, with demand increasing by over 250% in the past two years. Containerized energy storage solutions now account for approximately 45% of all new commercial and industrial storage deployments worldwide. North America leads with 42% market share, driven by corporate sustainability initiatives and tax incentives that reduce total project costs by 18-28%. Europe follows closely with 35% market share, where standardized industrial storage designs have cut installation timelines by 65% compared to traditional built-in-place systems. Asia-Pacific represents the fastest-growing region at 50% CAGR, with manufacturing scale reducing system prices by 20% annually. Emerging markets in Africa and Latin America are adopting industrial storage solutions for peak shaving and backup power, with typical payback periods of 2-4 years. Major commercial projects now deploy clusters of 15+ systems creating storage networks with 80+MWh capacity at costs below $270/kWh for large-scale industrial applications.

Industrial Energy System Innovations & Cost Benefits

Technological advancements are dramatically improving industrial energy storage performance while reducing costs. Next-generation battery management systems maintain optimal operating conditions with 45% less energy consumption, extending battery lifespan to 20+ years. Standardized plug-and-play designs have reduced installation costs from $85/kWh to $40/kWh since 2023. Smart integration features now allow multiple industrial systems to operate as coordinated energy networks, increasing cost savings by 30% through peak shaving and demand charge management. Safety innovations including multi-stage fire suppression and thermal runaway prevention systems have reduced insurance premiums by 35% for industrial storage projects. New modular designs enable capacity expansion through simple system additions at just $200/kWh for incremental capacity. These innovations have improved ROI significantly, with commercial and industrial projects typically achieving payback in 3-5 years depending on local electricity rates and incentive programs. Recent pricing trends show standard industrial systems (1-2MWh) starting at $330,000 and large-scale systems (3-6MWh) from $600,000, with volume discounts available for enterprise orders.