Example of the Number of PV Modules Connected in Series

Example of the Number of PV Modules Connected in Series In distributed scenarios, configure and design PV modules based on the actual limits and specifications to ensure that the

How big an inverter should I choose for a 20kw photovoltaic

How many kW does a solar inverter generate? For example, if your panels generate 10 kW: Minimum inverter size = 10,000 x 0.8 = 8 kW Maximum inverter size = 10,000 x 1.25 = 12.5 kW

Principles for Calculating the Number of PV Modules Connected in Series

Based on GB50797-2012 Code for design of photovoltaic power station, the recommended formula for calculating the number N * of PV modules connected in series is as follows: *: For

Design and Sizing of Solar Photovoltaic Systems

Feb 2, 2022 · DESIGN AND SIZING OF SOLAR PHOTOVOTAIC SYSTEMS Photovoltaic (PV) systems (or PV systems) convert sunlight into electricity using semiconductor materials. A

Test results and real cases of connecting different components

When designing a photovoltaic system, we should try to keep all the components of the same inverter consistent, but this is the most ideal situation. In fact, we will encounter many more

Inverters in Parallel vs. Series, Configure Power

Nov 24, 2023 · When it comes to optimizing power systems, the configuration of inverters—whether in parallel or in series—plays a crucial role in determining

Series, Parallel & Series-Parallel Connection of

3 days ago · To calculate the number of PV modules to be connected in series, the required voltage of the PV array should be given. We will also see the total

The PV panel configuration way of the string

Feb 26, 2024 · The string inverter is a key device used in solar power generation systems. It is responsible for converting the DC power generated by the solar

Will A 20kw Generator Run My House? What

Jan 15, 2024 · Choosing the right power generator is the key to getting a flawless power supply. But it is tricky to find out right power generator to run a full house.

How many panels can I wire in series for 48V system

Dec 30, 2023 · I have a 48V DC to 120V AV 5000W inverter. I''m a bit confused about how many panels I can wire in series. I''m assuming that I can wire four 12V panels in series (to get 48V),

Principles for Calculating the Number of PV Modules Connected in Series

Then, the number of PV modules connected in series needs to be properly designed through technical and economic comparisons based on factors such as PV module layout, DC

Solar Inverter String Design Calculations

Dec 11, 2023 · Solar Inverter String Design Calculations The following article will help you calculate the maximum/minimum number of modules per series string when designing your PV

How Many Solar Panels Can a 20kW Inverter Handle? Let''s

That''s essentially the "how many panels for a 20kW inverter" debate. While the theoretical maximum is 50 x 400W panels, real-world factors like panel efficiency, sunlight conditions, and

6 FAQs about [How many components should be connected in series for a 20kw inverter]

How to connect two power inverters in a series?

There are a few things you should bear in mind while connecting two power inverters in a series. First, ensure that the maximum current for each inverter is the same. Otherwise, it may have an impact on the power output of the series connection. Second, you should understand that an inverter is a DC-to-AC transformer.

How many solar panels can a MPPT inverter have?

The number of solar PV panels in each string must be at least 4 modules. The PV array must not exceed one string. This step is not required for the inverter MPPT with only one string. The PV generator (PV array) consists of one string, which is connected to the three-phase 5KW inverter.

How to size a solar power inverter?

During the inverter sizing you need to take into account the different configuration limits, which should be considered when sizing the solar power inverter (Data from the inverter and solar panel data sheets). During the sizing, the temperature coefficient is an important factor.

How many solar panels can a 600V inverter connect?

If an inverter has a maximum input voltage of 600V and each panel produces 40V, you could connect up to 15 panels in series (15 x 40V = 600V). Going over this voltage limit can harm the inverter or make it shut down, making your solar system less effective or even unusable. Equally important is the minimum input voltage.

How many types of inverters are there?

Inverters are grouped into three basic types based on their circuit layout. Series inverters, parallel inverters, and bridge inverters are the three types of inverters. In this article, let us learn about whether can you connect inverters in series and if so, then how to connect 2 inverters in series along with the operation of a series inverter.

How do I configure a series inverter?

For instance, if you have an inverter with a maximum input voltage of 100V and it supports up to 30A, you might configure your panels as follows: Series Connection Example: Three panels, each with 30V and 10A. Connect two sets in series (totaling 60V per set), then connect these sets in parallel (keeping within the limit).

Learn More

- How many volts can be output when 6 550w photovoltaic panels are connected in series

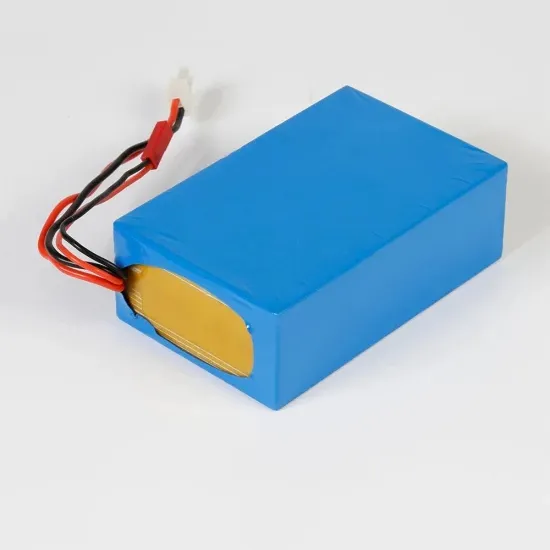

- Nine e series battery connected to inverter

- How many photovoltaic panels are connected to the inverter

- How much does it cost to buy a communication base station inverter

- How long can the energy storage inverter supply power

- How much does a communication base station inverter cost in Kabul

- How much does a photovoltaic DC inverter cabinet cost

- Car connected to 220v inverter

- How many hours can a 60v20A 220v inverter be used for

Industrial & Commercial Energy Storage Market Growth

The global industrial and commercial energy storage market is experiencing explosive growth, with demand increasing by over 250% in the past two years. Containerized energy storage solutions now account for approximately 45% of all new commercial and industrial storage deployments worldwide. North America leads with 42% market share, driven by corporate sustainability initiatives and tax incentives that reduce total project costs by 18-28%. Europe follows closely with 35% market share, where standardized industrial storage designs have cut installation timelines by 65% compared to traditional built-in-place systems. Asia-Pacific represents the fastest-growing region at 50% CAGR, with manufacturing scale reducing system prices by 20% annually. Emerging markets in Africa and Latin America are adopting industrial storage solutions for peak shaving and backup power, with typical payback periods of 2-4 years. Major commercial projects now deploy clusters of 15+ systems creating storage networks with 80+MWh capacity at costs below $270/kWh for large-scale industrial applications.

Industrial Energy System Innovations & Cost Benefits

Technological advancements are dramatically improving industrial energy storage performance while reducing costs. Next-generation battery management systems maintain optimal operating conditions with 45% less energy consumption, extending battery lifespan to 20+ years. Standardized plug-and-play designs have reduced installation costs from $85/kWh to $40/kWh since 2023. Smart integration features now allow multiple industrial systems to operate as coordinated energy networks, increasing cost savings by 30% through peak shaving and demand charge management. Safety innovations including multi-stage fire suppression and thermal runaway prevention systems have reduced insurance premiums by 35% for industrial storage projects. New modular designs enable capacity expansion through simple system additions at just $200/kWh for incremental capacity. These innovations have improved ROI significantly, with commercial and industrial projects typically achieving payback in 3-5 years depending on local electricity rates and incentive programs. Recent pricing trends show standard industrial systems (1-2MWh) starting at $330,000 and large-scale systems (3-6MWh) from $600,000, with volume discounts available for enterprise orders.