AC Inverter to charge portable bluetti power station while

Apr 20, 2024 · Will this work without any issues? 1000 WATT renogy inverter connected to the starter 12v 100ah battery with 4 feet of 4 gauge wire with an inline 150 amp anl fuse. The

Car Inverter, 12v DC to AC Power Inverter for Car | inverter

80w car power inverter, modified sine wave, DC 12v input to 220V AC output, advanced circuit design, high conversion efficiency up to 90%. Rated power 80w, peak power 160w. Adopting

Is the Car Inverter Safe? | inverter

Jun 21, 2022 · The power of a car refrigerator is generally 120W. It is not recommended to continue to connect other electrical equipment when the car refrigerator is connected, because

Inverter for Car: Everything You Need to Know Before You

Jun 17, 2025 · What Is a Car Power Inverter and How Does It Work? What Does an Inverter Do for a Car? Is a 2000 Watt Car Inverter Too Much for My Vehicle? What Can You Power with a

Installing a Power Inverter in a Car or Truck

Jul 5, 2025 · Installing a Power Inverter in a Car or Truck Installing a power inverter in a car or truck can significantly enhance its utility by allowing you to power electronic devices that

How to Pick the Right Power Inverter for Your Car

Jun 13, 2025 · In this article, you''ll get a practical guide to help you identify which inverter is best for your car setup. We aim to enable drivers, campers, and daily users to maintain power

Car Power Inverter Wiki, Buying Guide, Wiring/Circuit Diagrams

Car inverter can turn 12V into 220V. The inverter is still quite useful, but many people worry about car inverter will be harmful to the car battery. As long as the battery is used in automotive

How to Install a Power Inverter in a Car?

May 9, 2025 · If you want to know how to install a power inverter in a car, you are in the right place. In this article, you will get all the information in this regard.

Can I connect car alternator directly to the invertor

Apr 19, 2017 · , Can I connect car alternator directly to the invertor, UK Electrical Forum, ElectriciansForums Est.2006 | Free Electrical Advice Forum and page_number.

Installing a Power Inverter in a Car or Truck

Jul 5, 2025 · Installing a power inverter in a car or truck can significantly enhance its utility by allowing you to power electronic devices that require AC current, transforming your vehicle into

Power Inverters | Van & Car Inverters | Toolstation

Power Inverters At Toolstation, you can find high-quality power inverters from many trusted brands. With products available in a range of different wattages, you''re bound to find a suitable

Installing a Power Inverter in Your Car: Step-by-Step Guide

Jun 24, 2025 · Connecting your power inverter to a car battery requires careful attention to detail to ensure it is done safely and correctly. First, identify the positive and negative terminals of

6 FAQs about [Car connected to 220v inverter]

What is a car power inverter?

A car power inverter can be a lifesaver on a long road trip, camping excursion, and in a lot of other circumstances. Inverters are useful but have limitations. The inverter design and the method you use to connect it to your vehicle's electrical system limit the amount of power an inverter provides.

How do you permanently wire a car inverter?

One way you can permanently wire a car inverter is to tap into the power wire or go straight to the battery. If you opt to go straight to the battery, you'll have to find where the wiring harness passes through the firewall and fish the power wire through.

Do you need a car power inverter?

The utility provided by a good power inverter is handy for salespeople, truckers, and other people who spend a lot of time in their vehicles. A car power inverter can be a lifesaver on a long road trip, camping excursion, and in a lot of other circumstances. Inverters are useful but have limitations.

Can a car inverter be permanently wired?

For more power-intensive equipment and permanent installations, you'll need to do some wiring. One way you can permanently wire a car inverter is to tap into the power wire or go straight to the battery.

What is a car battery inverter?

A car battery inverter serves one main purpose: it allows you to use standard wall plugs in your vehicle. Think of it as a mini power station in your car. When you connect the inverter to your cigarette lighter port or directly to the car battery, it steps up and converts that 12V DC into usable 110V or 120V AC power—depending on where you live.

How do I install a car power inverter?

The easiest way to install a car power inverter is to plug it into a 12V accessory outlet. These outlets have traditionally been used for cigarette lighters, but many new vehicles eschew the lighter entirely. Some vehicles also have multiple outlets, or remote outlets, besides the one that's in the center console.

Learn More

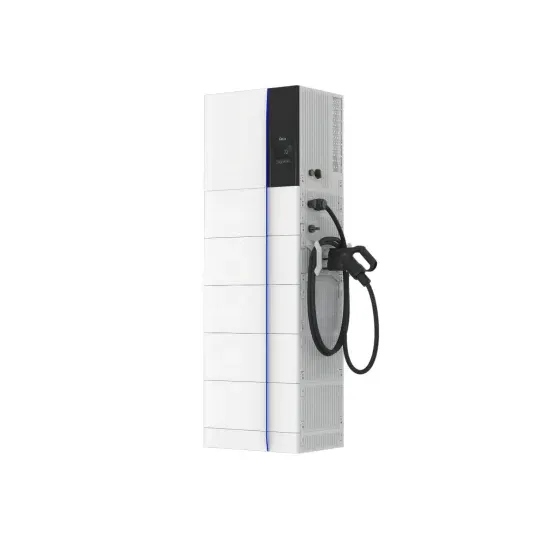

Industrial & Commercial Energy Storage Market Growth

The global industrial and commercial energy storage market is experiencing explosive growth, with demand increasing by over 250% in the past two years. Containerized energy storage solutions now account for approximately 45% of all new commercial and industrial storage deployments worldwide. North America leads with 42% market share, driven by corporate sustainability initiatives and tax incentives that reduce total project costs by 18-28%. Europe follows closely with 35% market share, where standardized industrial storage designs have cut installation timelines by 65% compared to traditional built-in-place systems. Asia-Pacific represents the fastest-growing region at 50% CAGR, with manufacturing scale reducing system prices by 20% annually. Emerging markets in Africa and Latin America are adopting industrial storage solutions for peak shaving and backup power, with typical payback periods of 2-4 years. Major commercial projects now deploy clusters of 15+ systems creating storage networks with 80+MWh capacity at costs below $270/kWh for large-scale industrial applications.

Industrial Energy System Innovations & Cost Benefits

Technological advancements are dramatically improving industrial energy storage performance while reducing costs. Next-generation battery management systems maintain optimal operating conditions with 45% less energy consumption, extending battery lifespan to 20+ years. Standardized plug-and-play designs have reduced installation costs from $85/kWh to $40/kWh since 2023. Smart integration features now allow multiple industrial systems to operate as coordinated energy networks, increasing cost savings by 30% through peak shaving and demand charge management. Safety innovations including multi-stage fire suppression and thermal runaway prevention systems have reduced insurance premiums by 35% for industrial storage projects. New modular designs enable capacity expansion through simple system additions at just $200/kWh for incremental capacity. These innovations have improved ROI significantly, with commercial and industrial projects typically achieving payback in 3-5 years depending on local electricity rates and incentive programs. Recent pricing trends show standard industrial systems (1-2MWh) starting at $330,000 and large-scale systems (3-6MWh) from $600,000, with volume discounts available for enterprise orders.