Power Tool Batteries: A Comprehensive Guide —

Nov 18, 2024 · This guide dives into the world of power tool batteries, exploring different chemistries, voltage platforms, amp-hour ratings, and maintenance

How To Choose A Power Tool Battery?

Aug 4, 2025 · There are many types of power tool batteries, with lithium-ion (Li-ion) batteries being the most common because of their high energy density, long life and light weight. They

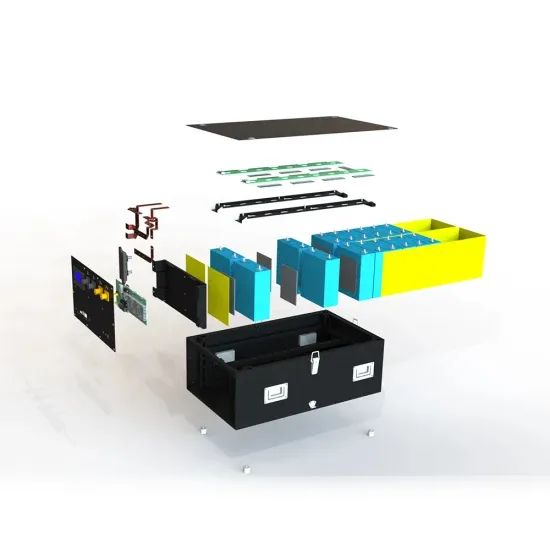

Understanding the Composition of Batteries and Battery Packs

Jun 6, 2025 · Understanding the composition and structure of batteries and battery packs is crucial as we move towards more sustainable and efficient energy solutions. Continued

Composition of Battery – en – Electricity – Magnetism

Jan 14, 2024 · 30-second summary Composition of Battery Batteries are made of an extensive range of materials resulting in different capabilities and behaviors in the functionality of the

Batteries for Power Tools | Reliable and Long-lasting

In conclusion, batteries for power tools are essential for the performance and portability of your power tools. When choosing the right battery, consider factors such as voltage and Ah rating.

Else_ECPS_364 46..52

Dec 18, 2013 · Introduction The name ''power tool'' originally describes a tool that is powered by an electrical motor. Thus, the effort needed by an operator is reduced through using this tool.

Power Tool Batteries Explained: Pick up the right battery

May 14, 2023 · Power tool batteries are the backbone of cordless power tools, providing the necessary power to make them work. These batteries eliminate

Navigating the Power Maze: My Ultimate Power Tool Battery

Oct 29, 2024 · While sniffing around for the best power tool battery scoop, I''ve stumbled on a real gem in lithium-ion batteries. Let me tell ya, these batteries have been a revelation for power

The Power Behind the Tools: Who Makes DeWalt Batteries?

Mar 14, 2025 · The Battery Manufacturing Process 1. Understanding Battery Composition DeWalt primarily uses lithium-ion batteries for its cordless tool lineup. These batteries are popular in

General Lithium Ion Battery Safety

When buying aftermarket batteries for power tools, it is important to consult with the power tool owner''s manual and purchase only the batteries recommended by the manufacturer. Only use

Types of Battery Chemistries and Comparison from Li-ion to

Battery chemistries are the heart of modern energy storage solutions, powering our devices, vehicles, and even homes. These chemistries represent diverse technologies, each with

Composition and state prediction of lithium-ion cathode via

May 4, 2024 · Lithium-ion battery (LIB) system consists of anode, cathode, electrolyte, separator to name few. The interaction between each component is very complicated, which hinders the

Essential Guide to Power Tool Batteries: Types,

Jan 25, 2025 · This guide delves into the technical aspects, types, and selection criteria for these batteries, highlighting the offerings from various Chinese manufacturers such as Semitech

Battery | Composition, Types, & Uses | Britannica

Aug 6, 2025 · Battery, in electricity and electrochemistry, any of a class of devices that convert chemical energy directly into electrical energy. Although the term

A Buyer''s Guide to Power Tool Batteries

Introduction Power tool batteries are a crucial component of any cordless power tool, providing the necessary power to perform various tasks in construction, electrical contracting,

What Are the Raw Materials Used in Lithium-Ion Batteries?

Apr 23, 2025 · Lithium-ion batteries are composed of several key raw materials that significantly influence their performance and efficiency. The primary materials include lithium, cobalt,

Battery Testing and Materials Characterization

Aug 31, 2000 · echnology with proven quality and performance. From R&D and material selection to manufacturing and quality control, TA Instruments'' solutions upport the full breadth of

Elemental Analysis & Testing in the Lithium-ion

Oct 19, 2022 · Elemental analysis of battery materials including cathode (various types and material composition), anode (mostly high-purity graphite),

Li-ion battery materials: present and future

Jun 1, 2015 · Li-ion batteries have an unmatchable combination of high energy and power density, making it the technology of choice for portable electronics, power tools, and hybrid/full electric

Understanding Different Types of Battery Compositions

Mar 5, 2025 · The shift towards electric vehicles (EVs) has sparked significant innovation in battery technology. As electric vehicles become more mainstream, automakers are constantly

Battery Composition → Term

Apr 16, 2025 · Meaning → Battery composition defines the specific materials within a battery, dictating its performance, cost, safety, and crucial lifecycle sustainability impacts.

6 FAQs about [Composition of tool batteries]

What chemistry is used in power tool batteries?

The Power Tool Institute is the leading organization for power tool safety resources, information and education. Li-Ion Batteries . For many years, the chemistry used in power tool batteries was commonly nickel metal hydride (Ni-MH) and nickel cadmium (Ni-Cd).

What type of battery does a power tool use?

Essentially, cordless instruments with higher voltage are all the more effective. Rechargeable power apparatus batteries are typically a group of individual cells. The consolidated voltage of the cells decides the battery’s general voltage. What shape of power tool battery are there?

Can you use a different battery on a power tool?

It’s not recommended to use a different brand’s battery on your power tool as the batteries are designed to work with each other. It may lead to damage to the tool or the battery, reducing their lifespan. What Is The Difference Between Nicad, Nimh, And Lithium-Ion Batteries?

Are power tool batteries cross-compatible?

For all these safety and compliance considerations, batteries are not cross-compatible (unless specified by the power tool manufacturer). When buying aftermarket batteries for power tools, it is important to consult with the power tool owner’s manual and purchase only the batteries recommended by the manufacturer.

How long do power tool batteries last?

Power tool batteries can last from one to five years or between 300 and 500 charges. Proper storage, temperature, and charging method can extend their life. How Do I Know If My Power Tool Battery Needs To Be Replaced? If your power tool battery doesn’t hold a charge after several hours or loses power quickly, it may need replacement.

How do you store a power tool battery?

Remove batteries from the power tool while storing for an extended period. The batteries can lose their charge over time, leading to less battery life. Keep tools and batteries away from moisture or humid places, as it can damage the battery.

Learn More

- Various types of tool batteries

- Electro-hydraulic tool batteries

- How many tool batteries are there

- Which brand is compatible with EK tool batteries

- How many cells are needed to charge tool lithium batteries

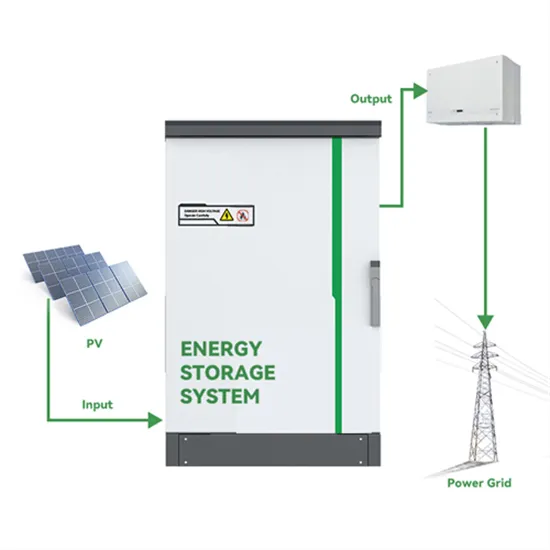

- Energy storage batteries reduce maximum demand

- Ranking of various energy storage batteries

- How to add batteries to solar energy storage cabinets

- Are maintenance-free lead-acid batteries suitable for inverters

Industrial & Commercial Energy Storage Market Growth

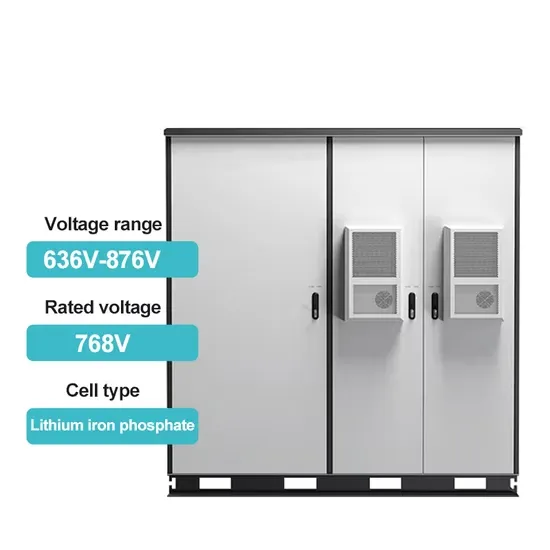

The global industrial and commercial energy storage market is experiencing explosive growth, with demand increasing by over 250% in the past two years. Containerized energy storage solutions now account for approximately 45% of all new commercial and industrial storage deployments worldwide. North America leads with 42% market share, driven by corporate sustainability initiatives and tax incentives that reduce total project costs by 18-28%. Europe follows closely with 35% market share, where standardized industrial storage designs have cut installation timelines by 65% compared to traditional built-in-place systems. Asia-Pacific represents the fastest-growing region at 50% CAGR, with manufacturing scale reducing system prices by 20% annually. Emerging markets in Africa and Latin America are adopting industrial storage solutions for peak shaving and backup power, with typical payback periods of 2-4 years. Major commercial projects now deploy clusters of 15+ systems creating storage networks with 80+MWh capacity at costs below $270/kWh for large-scale industrial applications.

Industrial Energy System Innovations & Cost Benefits

Technological advancements are dramatically improving industrial energy storage performance while reducing costs. Next-generation battery management systems maintain optimal operating conditions with 45% less energy consumption, extending battery lifespan to 20+ years. Standardized plug-and-play designs have reduced installation costs from $85/kWh to $40/kWh since 2023. Smart integration features now allow multiple industrial systems to operate as coordinated energy networks, increasing cost savings by 30% through peak shaving and demand charge management. Safety innovations including multi-stage fire suppression and thermal runaway prevention systems have reduced insurance premiums by 35% for industrial storage projects. New modular designs enable capacity expansion through simple system additions at just $200/kWh for incremental capacity. These innovations have improved ROI significantly, with commercial and industrial projects typically achieving payback in 3-5 years depending on local electricity rates and incentive programs. Recent pricing trends show standard industrial systems (1-2MWh) starting at $330,000 and large-scale systems (3-6MWh) from $600,000, with volume discounts available for enterprise orders.