Flywheel Energy Storage Costs Decoded: A 2024 Price

Feb 1, 2022 · Our analysis reveals why California''s latest 20MW flywheel installation spent 38% less than traditional battery farms. Who Needs This Price Breakdown? The $64,000 Question:

DOE ESHB Chapter 25: Energy Storage System Pricing

Sep 3, 2021 · This chapter summarizes energy storage capital costs that were obtained from industry pricing surveys. The survey methodology breaks down the cost of an energy storage

Energy Storage Technology and Cost Characterization

Jul 25, 2019 · Abstract This report defines and evaluates cost and performance parameters of six battery energy storage technologies (BESS) (lithium-ion batteries, lead-acid batteries, redox

Flywheel Energy Storage Systems and Their

Apr 1, 2024 · This study gives a critical review of flywheel energy storage systems and their feasibility in various applications. Flywheel energy storage systems

A review of flywheel energy storage rotor materials and

Oct 19, 2023 · The flywheel is the main energy storage component in the flywheel energy storage system, and it can only achieve high energy storage density when rotating at high speeds.

Flywheel Energy Storage Costs Decoded: A 2024 Price

Feb 1, 2022 · If you''re reading this, you''re probably wondering: "How much does a flywheel energy storage project ACTUALLY cost?" Let''s cut through the techno-babble. Unlike battery

Development and prospect of flywheel energy storage

Oct 1, 2023 · With the rise of new energy power generation, various energy storage methods have emerged, such as lithium battery energy storage, flywheel energy sto

Flywheel Energy Storage Cost per kWh: Efficiency Meets

Current flywheel energy storage costs vary by application: Singapore''s hybrid solar-flywheel microgrid achieved 94% round-trip efficiency at $1,620/kWh - 18% cheaper than equivalent

RotorVault Energy Storage Cost Analysis and Flywheel Price

5 days ago · RotorVault Flywheel Cost-Competitive Technology RotorVault''s storage product for data center applications is the most cost-competitive solution offering both backup power for

A review of flywheel energy storage systems: state of the

Mar 15, 2021 · This paper gives a review of the recent Energy storage Flywheel Renewable energy Battery Magnetic bearing developments in FESS technologies. Due to the highly

flywheel energy storage installation and construction costs

Torus Flywheel Energy Storage System (FESS) Greener Energy Storage. The Torus Flywheel ranks among the world''''s most environmentally friendly batteries. It''''s made with 95%

Flywheel energy storage construction cost budget

Flywheel energy storage systems can also help you manage your electricity costs by providing a source of backup energy when the grid goes down. Contrary to expensive and harmful diesel

High-tension, vertical filament winding enables

Mar 5, 2025 · High-tension, vertical filament winding enables affordable flywheel energy storage system French startup Energiestro''s prototype solar energy

Cost-Benefit Analysis of Flywheel Energy Storage in context of flywheel

Aug 27, 2024 · Flywheel energy storage (FES) is a promising technology that has gained significant attention in recent years due to its potential to mitigate the intermittency of

Flywheel Energy Storage Systems and their Applications:

Oct 19, 2024 · However, the high cost of purchase and maintenance of solar batteries has been a major hindrance. Flywheel energy storage systems are suitable and economical when

A comprehensive review of Flywheel Energy Storage System

Jan 1, 2017 · Energy storage systems (ESSs) play a very important role in recent years. Flywheel is one of the oldest storage energy devices and it has several benefits. Flywheel Energy

Flywheel energy storage cost calculation scheme

The energy storage scheme is configured in combination with the objective function of the lowest cost and lowest volatility with the construction of battery-flywheel storage stations.

Flywheel Energy Storage Construction Cost Budget List Key

Flywheel energy storage systems (FESS) are gaining traction as sustainable alternatives to traditional batteries. But what does it cost to build one? Let''s break down the flywheel energy

The development of a techno-economic model for the

Oct 1, 2021 · Two rotor configurations were considered: composite rotor flywheel and steel rotor flywheel. The total investment costs of the composite rotor and steel rotor flywheel storage

Energy storage management in a near zero energy building

Apr 1, 2025 · In the present study, a dynamic analysis of a photovoltaic (PV) system integrated with two electrochemical storage systems, lithium-ion and lead acid batteries, and a flywheel

Understanding the Cost of Flywheel Energy Storage Systems:

Jun 16, 2019 · Let''s pop the trunk on flywheel costs: Material Costs: That fancy carbon-fiber rotor? About 40% of the total bill. Recent data from the U.S. Department of Energy shows

Flywheel Energy Storage Costs: Breaking Down the

Current flywheel installations average $1,100-$1,500 per kW compared to $700-$900/kW for lithium batteries [1] [10]. However, when considering total lifecycle value, the picture changes

Technology: Flywheel Energy Storage

Oct 30, 2024 · Summary of the storage process Flywheel Energy Storage Systems (FESS) rely on a mechanical working principle: An electric motor is used to spin a rotor of high inertia up to

The Real Cost of Flywheel Energy Storage: Breaking Down

When someone says "energy storage," your mind probably jumps to lithium-ion batteries - the rockstars of the renewable energy world. But there''s a dark horse candidate doing donuts in

The Flywheel Energy Storage System: A Conceptual

Feb 16, 2024 · cost-effective storage discharge) applications, batteries. Despite construction costs, the the flywheels has quality applications. features that make solution for future pollution

6 FAQs about [Flywheel energy storage construction cost]

Are flywheel energy storage systems economically feasible?

Equipment cost distribution for the flywheel energy storage systems. FESSs are used for short-duration power applications. Therefore, power capital cost ($/kW) could be a useful parameter to compare the economic feasibility of energy storage systems for similar power applications.

How much does a steel rotor flywheel cost?

The steel rotor flywheel has a lower capital cost and levelized cost of storage. The costs of composite and steel rotor flywheels are $190 and $146/MWh, respectively. Flywheel energy storage systems are increasingly being considered as a promising alternative to electro-chemical batteries for short-duration utility applications.

Does a flywheel storage system need a bottom-up research?

However, almost no bottom-up research has been done, i.e., research that considers the technical parameters to size the components of a flywheel storage system, estimate cost parameters based on the design, and provide a probable distribution of the total investment cost and levelized cost of storage.

What is the power rating of a flywheel energy storage system?

Utility-scale energy storage systems for stationary applications typically have power ratings of 1 MW or more . The largest flywheel energy storage is in New York, USA by Beacon Power with a power rating of 20 MW and 15 min discharge duration .

How much does a flywheel power converter cost?

The costs of a power converter for composite and steel flywheels are $49,618 and $52,595, respectively. The cost difference is due to the difference in rated power, 100 kW for the composite flywheel and 108 kW for the steel flywheel. Fig. 5. Equipment cost distribution for the flywheel energy storage systems.

How can flywheels be more competitive to batteries?

The use of new materials and compact designs will increase the specific energy and energy density to make flywheels more competitive to batteries. Other opportunities are new applications in energy harvest, hybrid energy systems, and flywheel’s secondary functionality apart from energy storage.

Learn More

- Construction skills of flywheel energy storage for communication base stations

- Paris Flywheel Energy Storage Construction Preparations

- Flywheel energy storage investment cost per kilowatt

- 5g communication base station flywheel energy storage construction

- How much does the Cape Verde energy storage system cost

- How much does a 5MWh energy storage container cost at CRRC Barcelona Spain

- Kuala Lumpur photovoltaic energy storage integrated machine cost

- Construction of the Skopje wind solar and energy storage project

- How much does St George s energy storage equipment cost

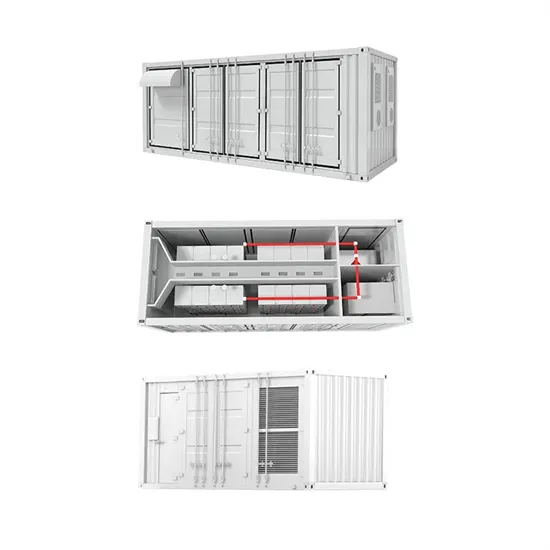

Industrial & Commercial Energy Storage Market Growth

The global industrial and commercial energy storage market is experiencing explosive growth, with demand increasing by over 250% in the past two years. Containerized energy storage solutions now account for approximately 45% of all new commercial and industrial storage deployments worldwide. North America leads with 42% market share, driven by corporate sustainability initiatives and tax incentives that reduce total project costs by 18-28%. Europe follows closely with 35% market share, where standardized industrial storage designs have cut installation timelines by 65% compared to traditional built-in-place systems. Asia-Pacific represents the fastest-growing region at 50% CAGR, with manufacturing scale reducing system prices by 20% annually. Emerging markets in Africa and Latin America are adopting industrial storage solutions for peak shaving and backup power, with typical payback periods of 2-4 years. Major commercial projects now deploy clusters of 15+ systems creating storage networks with 80+MWh capacity at costs below $270/kWh for large-scale industrial applications.

Industrial Energy System Innovations & Cost Benefits

Technological advancements are dramatically improving industrial energy storage performance while reducing costs. Next-generation battery management systems maintain optimal operating conditions with 45% less energy consumption, extending battery lifespan to 20+ years. Standardized plug-and-play designs have reduced installation costs from $85/kWh to $40/kWh since 2023. Smart integration features now allow multiple industrial systems to operate as coordinated energy networks, increasing cost savings by 30% through peak shaving and demand charge management. Safety innovations including multi-stage fire suppression and thermal runaway prevention systems have reduced insurance premiums by 35% for industrial storage projects. New modular designs enable capacity expansion through simple system additions at just $200/kWh for incremental capacity. These innovations have improved ROI significantly, with commercial and industrial projects typically achieving payback in 3-5 years depending on local electricity rates and incentive programs. Recent pricing trends show standard industrial systems (1-2MWh) starting at $330,000 and large-scale systems (3-6MWh) from $600,000, with volume discounts available for enterprise orders.