(PDF) Battery Current and Voltage Control

Oct 8, 2014 · This paper presents the design of battery charging control system suitable for different battery types. A PI controller-based battery current control

Battery Charging Calculator – IEC, IEEE

Apr 19, 2025 · Essential Formulas for Battery Charging Calculations (IEC & IEEE) Battery charging calculations rely on several fundamental formulas to determine charging current,

Base station battery charging load current

Why does a base station have a low power load? Therefore, when the electricity price was at its peak, the base station system had a low power load and would discharge to the grid in part of

EV charging load profile identification and seasonal

Feb 1, 2024 · In addition, the identified typical charging load profiles can also inform the development of strategies to mitigate charging congestion, including charging queue

Hybrid Control Strategy for 5G Base Station

Sep 2, 2024 · Furthermore, a multi-objective joint peak shaving model for base stations is established, centrally controlling the energy storage system of the

Battery Sizing Considerations IEEE 2020

Mar 11, 2020 · NiCad batteries typically operate between 1.00vpc and up to 1.65vpc depending on load voltage tolerance. 125Vdc: 105Vdct to 140Vdc *Should be based on equipment

Li-Ion Cells: Charging and Discharging Explained

Jun 12, 2024 · It''s crucial to know how to charge and discharge li-ion cells. This article will provide you with a guide on the principles, currents, voltages, and

Load Profile Generator for Electric Vehicle Home Charging

May 9, 2023 · The load profile reflects the resulting energy demand of 30 different mobility characteristics, from student to manager. 21 charging stations offer an output of 3,7 kW and 9

A Guide to Understanding Battery Specifications

Dec 18, 2008 · A battery is a device that converts chemical energy into electrical energy and vice versa. This summary provides an introduction to the terminology used to describe, classify,

Charging Load vs. Station Service Load at Electric

Jan 8, 2023 · Charging Load vs. Station Service Load at Electric Storage Facilities Implementation of FERC Order 841 rules associated with the transmission cost exemption for

What is the purpose of batteries at telecom base

Feb 10, 2025 · The lead storage battery is the most widely used energy storage battery in the current communication power supply. Among the many types of

Optimal Electricity Dispatch for Base Stations with Battery

Jul 11, 2022 · With the development of newer communication technology, considering the higher electricity consumption and denser physical distribution, the base stations becom

Base station battery charging current

If the PV power exceeds the base station load, priority is given to charging the energy storage battery. However, if the energy storage battery cannot fully absorb the excess generated

Voltage‐dependent modelling of fast charging

Dec 1, 2018 · Here it is assumed that the battery of EVs coming to the charging station will not be completely depleted and it will be charged to a certain SOC

Efficient Management of Electric Vehicle Charging Stations:

It conducts a hypothetical case study on a commercial Evie network (charging company) charging station having 4 ultra-fast charging ports, in Australia, to investigate three load management

base station power battery management system

The utility model relates to lithium battery administrative skill fields, concretely it is related to base station power battery management system, including charger module and battery

Performance Analysis of VRLA Battery for DC Load at

Mar 5, 2022 · Previous research aims to determine the energy efficiency of the lead acid battery through the charging process with the constant current method of 0.3 A, 0.5 A, and 0.6 A.

Understanding Instantaneous Load and Charger Capacity

Jun 7, 2025 · In modern substations, accurate power system design requires a clear understanding of instantaneous (transient) loads and how they impact equipment sizing,

Optimum sizing and configuration of electrical system for

Jul 1, 2025 · Proposed a model for optimal sizing & resources dispatch for telecom base stations. The objective is to achieve 100% power availability while minimizing the cost. Results were

Solar Powered Cellular Base Stations: Current Scenario,

Dec 17, 2015 · Cellular base stations powered by renewable energy sources such as solar power have emerged as one of the promising solutions to these issues. This article presents an

Battery Charging

Apr 1, 2023 · The complexity (and cost) of the charging system is primarily dependent on the type of battery and the recharge time. This chapter will present charging methods, end-of-charge

6 FAQs about [Base station battery charging load current]

How to charge a battery?

Battery Charge–Discharge form a) Initial charge. equalize the voltage on each battery cell. capacity against a constant load. keep the battery full. current in the battery. f) C-rate of the rectifier module. To charge the battery current charger) is required according to the C-rate. III. RESULTS AND DISCUSSION amount of charging current.

How long does it take to charge a battery?

Typical charging current: 0.1C to 0.3C Charging time: 6–12 hours Efficiency: ~80% Typical charging current: 0.5C to 1C Charging time: 1–3 hours Efficiency: ~95% Typical charging current: 0.5C Charging time: 2–4 hours Efficiency: ~90% Tips to Optimize Charging Current and Time

How complex is a battery charging system?

The complexity (and cost) of the charging system is primarily dependent on the type of battery and the recharge time. This chapter will present charging methods, end-of-charge-detection techniques, and charger circuits for use with Nickel-Cadmium (Ni-Cd), Nickel Metal-Hydride (Ni-MH), and Lithium-Ion (Li-Ion) batteries.

What is charging current & charging time?

Charging current is the rate at which electrical energy is delivered to a battery. It’s typically measured in amperes (A). This value depends on the battery's capacity and the charger's output. What Is Charging Time? Charging time refers to the duration it takes to fully replenish a battery from a given state of charge (SOC) to 100%.

What is a 1C charge rate?

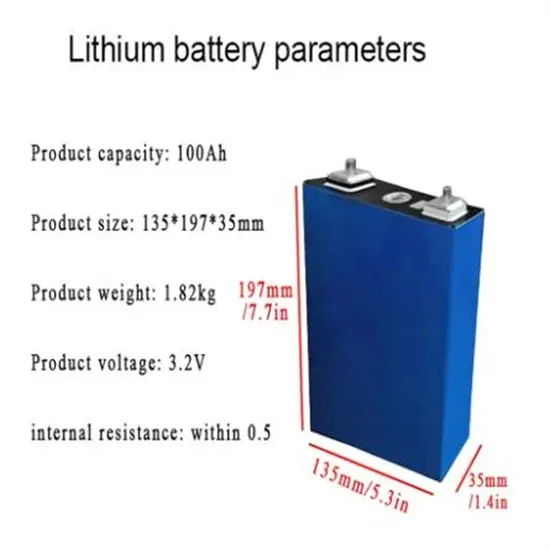

The C-rate is a key concept in battery charging. It defines the rate at which a battery is charged or discharged relative to its capacity. A 1C rate for a 100Ah battery means charging at 100A, which would theoretically fully charge the battery in 1 hour. Formula to Calculate Charging Current and Time

What is a good charging current for a lithium battery?

Charging Current: 20A (0.2C recommended for lead-acid) Efficiency: 80% Battery: 50Ah Charging Current: 25A (0.5C is safe for most lithium batteries) Efficiency: 95% Recommended Charging Current and Time by Battery Type Different batteries require different charging rates. Understanding these helps optimize Charging Current and Time.

Learn More

- Mobile base station battery pack charging current

- Battery cabinet base station power current abnormality

- Base station battery charging module

- Base station battery host computer current

- Communication base station battery energy storage system secondary load

- How to start charging the base station lithium battery

- How to measure the battery current of a base station

- The temperature of the battery energy storage system of the outdoor communication base station is too high

- The composition of the battery energy storage system of 5g communication base station

Industrial & Commercial Energy Storage Market Growth

The global industrial and commercial energy storage market is experiencing explosive growth, with demand increasing by over 250% in the past two years. Containerized energy storage solutions now account for approximately 45% of all new commercial and industrial storage deployments worldwide. North America leads with 42% market share, driven by corporate sustainability initiatives and tax incentives that reduce total project costs by 18-28%. Europe follows closely with 35% market share, where standardized industrial storage designs have cut installation timelines by 65% compared to traditional built-in-place systems. Asia-Pacific represents the fastest-growing region at 50% CAGR, with manufacturing scale reducing system prices by 20% annually. Emerging markets in Africa and Latin America are adopting industrial storage solutions for peak shaving and backup power, with typical payback periods of 2-4 years. Major commercial projects now deploy clusters of 15+ systems creating storage networks with 80+MWh capacity at costs below $270/kWh for large-scale industrial applications.

Industrial Energy System Innovations & Cost Benefits

Technological advancements are dramatically improving industrial energy storage performance while reducing costs. Next-generation battery management systems maintain optimal operating conditions with 45% less energy consumption, extending battery lifespan to 20+ years. Standardized plug-and-play designs have reduced installation costs from $85/kWh to $40/kWh since 2023. Smart integration features now allow multiple industrial systems to operate as coordinated energy networks, increasing cost savings by 30% through peak shaving and demand charge management. Safety innovations including multi-stage fire suppression and thermal runaway prevention systems have reduced insurance premiums by 35% for industrial storage projects. New modular designs enable capacity expansion through simple system additions at just $200/kWh for incremental capacity. These innovations have improved ROI significantly, with commercial and industrial projects typically achieving payback in 3-5 years depending on local electricity rates and incentive programs. Recent pricing trends show standard industrial systems (1-2MWh) starting at $330,000 and large-scale systems (3-6MWh) from $600,000, with volume discounts available for enterprise orders.