The role of energy storage systems for a secure energy

Nov 1, 2024 · Energy storage systems will be fundamental for ensuring the energy supply and the voltage power quality to customers. This survey paper offers an overview on potential energy

What does a chemical energy storage power station include?

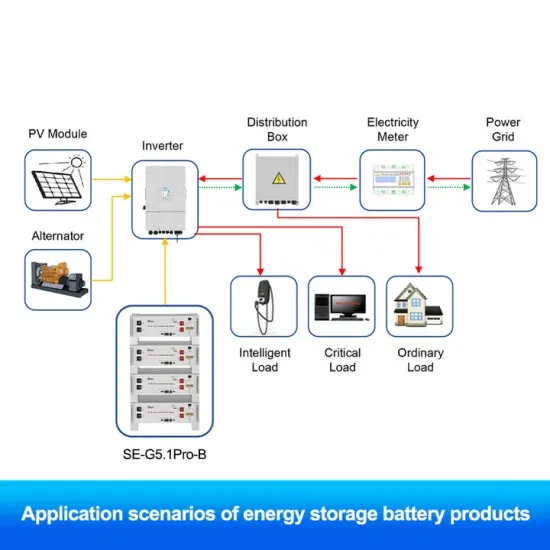

Apr 26, 2024 · A chemical energy storage power station comprises several key components: 1. Storage Medium – various forms of chemical substances used to store energy. 2. Conversion

Energy Storage for Power Systems

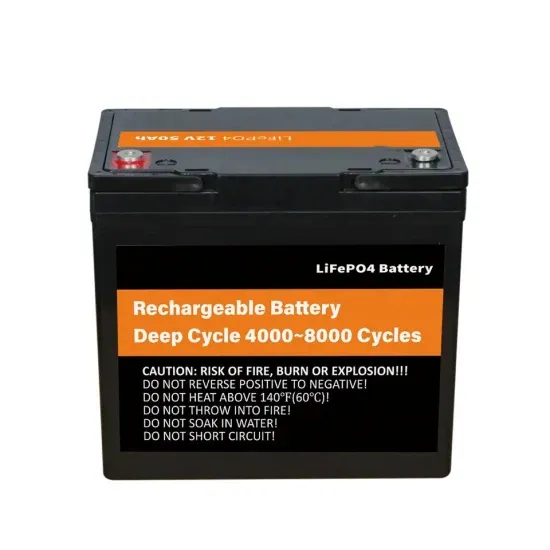

Jul 3, 2024 · The most traditional of all energy storage devices for power systems is electrochemical energy storage (EES), which can be classified into three categories: primary

Novel chemical integration of biodegradable energy storage

Incorporating bio-degradable components into energy storage systems can minimize environmental impact while maintaining high performance. Future efforts should focus on

AN INTRODUCTION TO BATTERY ENERGY STORAGE

Jul 15, 2024 · Battery energy storage systems are installed with several hardware components and hazard-prevention features to safely and reliably charge, store, and discharge electricity.

Comprehensive review of energy storage systems

Jul 1, 2024 · This paper presents a comprehensive review of the most popular energy storage systems including electrical energy storage systems, electrochemical energy storage systems,

Chemical Energy Storage (CES): How to Store Energy Inside a

Aug 12, 2023 · Chemical energy storage systems (CES), which are a proper technology for long-term storage, store the energy in the chemical bonds between the atoms and molecules of the

Definition and Classification of Energy Storage Systems

Sep 28, 2019 · Who is responsible for covering the costs of storage systems? To categorize storage systems in the energy sector, they first need to be carefully defined. This chapter

What do energy storage components store? | NenPower

Feb 20, 2024 · Energy storage components primarily store 1. Electrical energy, 2. Thermal energy, 3. Chemical energy, 4. Mechanical energy. Each type of energy storage serves

Energy storage technologies: An integrated survey of

Nov 30, 2023 · Abstract Energy Storage Technology is one of the major components of renewable energy integration and decarbonization of world energy systems. It significantly benefits

6 FAQs about [Components of chemical energy storage systems]

What is chemical energy storage?

Chemical energy storage is defined as the utilization of chemical species or materials to extract energy immediately or latently through processes such as physical sorption, chemical sorption, intercalation, electrochemical reactions, or chemical transformation. You might find these chapters and articles relevant to this topic.

What are the key factors for chemical energy storage materials?

The key factors for such kinds of chemical energy storage materials are as follows: Large density; Easy to store and transport; Compatible to the existing infrastructure; Easy to produce and high round-trip efficiency; Environment friendly.

How does chemical storage work?

Depending on how it is stored, it can be kept over long periods and is not seasonally dependent like pumped hydro. Chemical storage can add power into the grid and also store excess power from the grid for later use. Alternatively, many chemicals used for energy storage, like hydrogen, can decarbonize industry and transportation.

What is electrochemical energy storage system (ecess)?

Electrochemical energy storage systems (ECESS) ECESS converts chemical to electrical energy and vice versa . ECESS are Lead acid, Nickel, Sodium –Sulfur, Lithium batteries and flow battery (FB) .

What are the most popular energy storage systems?

This paper presents a comprehensive review of the most popular energy storage systems including electrical energy storage systems, electrochemical energy storage systems, mechanical energy storage systems, thermal energy storage systems, and chemical energy storage systems.

Why is electricity storage system important?

The use of ESS is crucial for improving system stability, boosting penetration of renewable energy, and conserving energy. Electricity storage systems (ESSs) come in a variety of forms, such as mechanical, chemical, electrical, and electrochemical ones.

Learn More

- Battery energy storage types for power systems

- Chemical energy storage power station related

- Supply of containerized energy storage systems in the Balkan Peninsula

- West Africa Chemical Energy Storage Power Station

- Reykjavik Chemical Energy Storage Plant

- Southern Region Chemical Energy Storage Power Station

- Price of chemical energy storage in photovoltaic power plants

- Fiji Chemical Energy Storage Project

- Influencing factors of chemical energy storage devices

Industrial & Commercial Energy Storage Market Growth

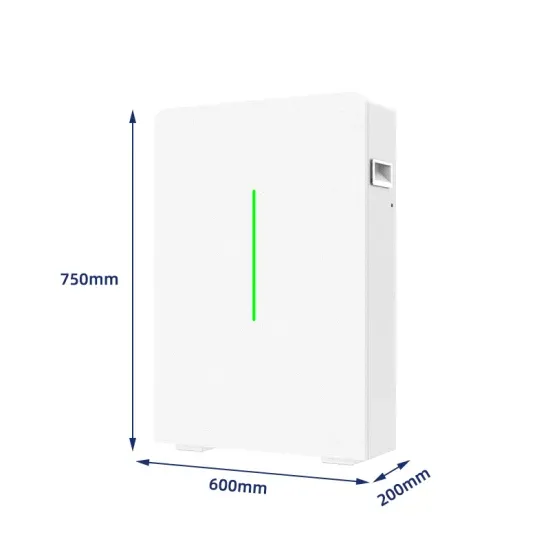

The global industrial and commercial energy storage market is experiencing explosive growth, with demand increasing by over 250% in the past two years. Containerized energy storage solutions now account for approximately 45% of all new commercial and industrial storage deployments worldwide. North America leads with 42% market share, driven by corporate sustainability initiatives and tax incentives that reduce total project costs by 18-28%. Europe follows closely with 35% market share, where standardized industrial storage designs have cut installation timelines by 65% compared to traditional built-in-place systems. Asia-Pacific represents the fastest-growing region at 50% CAGR, with manufacturing scale reducing system prices by 20% annually. Emerging markets in Africa and Latin America are adopting industrial storage solutions for peak shaving and backup power, with typical payback periods of 2-4 years. Major commercial projects now deploy clusters of 15+ systems creating storage networks with 80+MWh capacity at costs below $270/kWh for large-scale industrial applications.

Industrial Energy System Innovations & Cost Benefits

Technological advancements are dramatically improving industrial energy storage performance while reducing costs. Next-generation battery management systems maintain optimal operating conditions with 45% less energy consumption, extending battery lifespan to 20+ years. Standardized plug-and-play designs have reduced installation costs from $85/kWh to $40/kWh since 2023. Smart integration features now allow multiple industrial systems to operate as coordinated energy networks, increasing cost savings by 30% through peak shaving and demand charge management. Safety innovations including multi-stage fire suppression and thermal runaway prevention systems have reduced insurance premiums by 35% for industrial storage projects. New modular designs enable capacity expansion through simple system additions at just $200/kWh for incremental capacity. These innovations have improved ROI significantly, with commercial and industrial projects typically achieving payback in 3-5 years depending on local electricity rates and incentive programs. Recent pricing trends show standard industrial systems (1-2MWh) starting at $330,000 and large-scale systems (3-6MWh) from $600,000, with volume discounts available for enterprise orders.