Recent advancement in metal-organic frameworks for hydrogen storage

Sep 19, 2024 · In this review, we summarize the recent and important progress of MOFs for hydrogen storage, and provide a comprehensive understanding by exploring the influencing

Energy efficiency of lithium-ion batteries: Influential factors

Dec 25, 2023 · Abstract As the integration of renewable energy sources into the grid intensifies, the efficiency of Battery Energy Storage Systems (BESSs), particularly the energy efficiency of

Redox-active molecules for aqueous electrolytes of energy storage

Dec 1, 2024 · The increasing demand for aqueous energy storage (AES) solutions with high energy density, enlarged voltage windows, and extended cycling stability has spurred the

Fundamental chemical and physical properties of electrolytes in energy

Mar 15, 2024 · Performance of electrolytes used in energy storage system i.e. batteries, capacitors, etc. are have their own specific properties and several factors which can drive the

Wood for Application in Electrochemical Energy Storage

Dec 21, 2021 · For electrochemical energy storage devices, the electrode material is the key factor to determine their charge storage capacity. Research shows that the traditional pow-der

Progress and challenges in electrochemical energy storage devices

Jul 15, 2023 · Energy storage devices are contributing to reducing CO 2 emissions on the earth''s crust. Lithium-ion batteries are the most commonly used rechargeable batteries in

Cell chemistry is ''tip of the iceberg'' among

Oct 22, 2020 · The specific cell chemistry chosen by rechargeable lithium-ion battery manufacturers and suppliers may be the "most visible" characteristic of

Recent trends of machine learning on energy storage devices

Mar 1, 2025 · The study of materials for energy storage applications has been revolutionized by machine learning (ML), in particular. With an emphasis on electrochemical energy storage

Chemical Energy Storage | SpringerLink

Sep 28, 2019 · Chemical-energy storage is the backbone of today''s conventional energy supply. Solid (wood and coal), liquid (mineral oil), and gaseous (natural gas) energy carriers are

Analysis of Influencing Factors of Battery Cabinet Heat

Analysis of Influencing Factors of Battery Cabinet Heat Dissipation in Electrochemical Energy Storage System [J]. Journal of Electrical Engineering, 2022, 17 (1): 225-233.

What is graphite oxide? | Jinsun Carbon

Dec 1, 2024 · Graphite oxide is an important carbon-based material. It has attracted great attention in many fields such as energy storage, catalysis and composite materials due to its

Wood for Application in Electrochemical Energy Storage

Dec 21, 2021 · Herein, we comprehensively overview the methodologies applied for the synthesis of various electro-chemical energy storage systems and devices (e.g., supercapaci-tor,

Decay model of energy storage battery life under

2 Semi-empirical life decay modeling for lithium-ion batteries At present, most of the battery life attenuation models of energy storage are based on the irreversible capacity of the battery, and

Thermal properties of composite organic phase change materials

Nov 25, 2020 · In addition, approaches and materials employed for composite synthesis are described. Challenges and factors influencing the thermal energy storage performance of

Electrochemical and Chemical Energy Storage

Aug 14, 2025 · In the dynamic realm of energy storage and conversion, our course provides a comprehensive exploration of electrochemical devices, ranging from batteries and fuel cells to

Energy efficiency of lithium-ion batteries: Influential factors

Dec 25, 2023 · As the integration of renewable energy sources into the grid intensifies, the efficiency of Battery Energy Storage Systems (BESSs), particularly the energy efficiency of the

The Chemistry of Sustainable Energy Conversion and Storage

Excitingly, owing to the advancement of materials synthesis, chemical modifications, and characterization techniques, the chemistry behind sustainable energy conversion and storage

Recent Advances in Electrochemical Energy Storage: The Chemical

Jan 25, 2024 · Energy storage technologies like batteries, supercapacitors, and fuel cells bridge the gap between energy conversion and consumption, ensuring a reliable energy supply. From

Fundamental chemical and physical properties of electrolytes

Jan 9, 2024 · Electrolytes are indispensable and essential constituents of all types of energy storage devices (ESD) including batteries and capacitors. They have shown their importance

Li+-migration influencing factors and non-destructive life

Apr 19, 2025 · Polymer electrolytes are promising but are limited by narrow electrochemical window. Here, authors develop a family of in situ polymerized gel electrolytes with long term

6 FAQs about [Influencing factors of chemical energy storage devices]

What determines the stability and safety of electrochemical energy storage devices?

The stability and safety, as well as the performance-governing parameters, such as the energy and power densities of electrochemical energy storage devices, are mostly decided by the electronegativity, electron conductivity, ion conductivity, and the structural and electrochemical stabilities of the electrode materials. 1.6.

What are the key factors for chemical energy storage materials?

The key factors for such kinds of chemical energy storage materials are as follows: Large density; Easy to store and transport; Compatible to the existing infrastructure; Easy to produce and high round-trip efficiency; Environment friendly.

What are electrochemical energy storage devices?

Electrochemical energy storage Electrochemical storage devices, such as Li-ion batteries (LIBs), fuel cells, Li-S batteries, and supercapacitors have great potential to provide increased power and energy density.

Why is chemical-energy storage important?

This again demonstrates the crucial role of chemical-energy storage. It also illustrates that, in comparison with other storage, the energy density of chemical-energy storage is by far the highest. Power plant facilities have coal stockpiles with capacities ranging from several tens of thousands of tons to several hundreds of thousands of tons.

What is chemical energy storage technologies (CEST)?

oyment of chemical energy storage technologies (CEST). In the context of this report, CEST is defined as energy storage through the conversion of electric ty to hydrogen or other chemicals and synthetic fuels. On the basis of an analysis of the H2020 project portfolio and funding distribution, the report maps re

What is chemical energy storage?

Chemical energy storage is defined as the utilization of chemical species or materials to extract energy immediately or latently through processes such as physical sorption, chemical sorption, intercalation, electrochemical reactions, or chemical transformation. You might find these chapters and articles relevant to this topic.

Learn More

- What are the electrochemical energy storage devices

- What are the temperature control devices for solar energy storage cabinets

- Large Energy Storage Devices

- What are the energy storage power module devices

- Industrial Energy Storage Devices

- What are the types of flywheel energy storage devices

- What are the solar energy storage devices in Cuba

- Common energy storage devices for mechanical equipment

- Energy storage devices and UPS

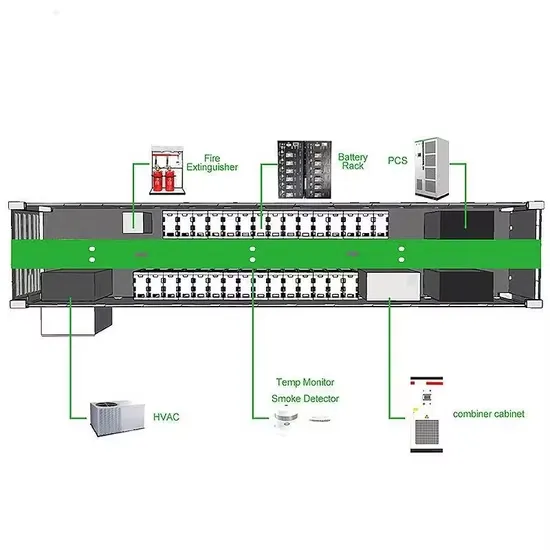

Industrial & Commercial Energy Storage Market Growth

The global industrial and commercial energy storage market is experiencing explosive growth, with demand increasing by over 250% in the past two years. Containerized energy storage solutions now account for approximately 45% of all new commercial and industrial storage deployments worldwide. North America leads with 42% market share, driven by corporate sustainability initiatives and tax incentives that reduce total project costs by 18-28%. Europe follows closely with 35% market share, where standardized industrial storage designs have cut installation timelines by 65% compared to traditional built-in-place systems. Asia-Pacific represents the fastest-growing region at 50% CAGR, with manufacturing scale reducing system prices by 20% annually. Emerging markets in Africa and Latin America are adopting industrial storage solutions for peak shaving and backup power, with typical payback periods of 2-4 years. Major commercial projects now deploy clusters of 15+ systems creating storage networks with 80+MWh capacity at costs below $270/kWh for large-scale industrial applications.

Industrial Energy System Innovations & Cost Benefits

Technological advancements are dramatically improving industrial energy storage performance while reducing costs. Next-generation battery management systems maintain optimal operating conditions with 45% less energy consumption, extending battery lifespan to 20+ years. Standardized plug-and-play designs have reduced installation costs from $85/kWh to $40/kWh since 2023. Smart integration features now allow multiple industrial systems to operate as coordinated energy networks, increasing cost savings by 30% through peak shaving and demand charge management. Safety innovations including multi-stage fire suppression and thermal runaway prevention systems have reduced insurance premiums by 35% for industrial storage projects. New modular designs enable capacity expansion through simple system additions at just $200/kWh for incremental capacity. These innovations have improved ROI significantly, with commercial and industrial projects typically achieving payback in 3-5 years depending on local electricity rates and incentive programs. Recent pricing trends show standard industrial systems (1-2MWh) starting at $330,000 and large-scale systems (3-6MWh) from $600,000, with volume discounts available for enterprise orders.