Contacting of 18650 lithium-ion batteries and copper bus

Jan 1, 2020 · Lithium-ion cell based battery storages are indispensable in many fields of application such as electromobility and stationary energy storage devices. Cylindrical 18650

Cell Contacting System-CCS

May 21, 2025 · Cell Contacting System-CCS Cell contacting systems for lithium-ion bateries of various configuration levels from ElringKlinger are matched exactly to customer specifications

Innovative Polymer Battery Solutions

Simply put, cylindrical battery assembly involves connecting multiple individual cylindrical cells (like common AA or AAA batteries) to create a larger battery pack. This pack can provide

Lithium battery cylindrical model, cylindrical

Aug 1, 2025 · 1. What is a cylindrical lithium battery? 1. Definition of cylindrical battery Cylindrical lithium batteries are divided into lithium iron phosphate,

Battery Pack Design of Cylindrical Lithium-Ion Cells and

Sep 12, 2022 · Battery Pack Design of Cylindrical Lithium-Ion Cells and Modelling of Prismatic Lithium-Ion Battery Based on Characterization Tests By Ruiwen Chen, B.Eng. & Co-op.

Chapter 31: Simulating a Single Battery Cell Using the MSMD

The discharge behavior of a lithium-ion battery described in Kim''s paper [2] will be modeled in this tutorial. You will use the NTGK model. The battery is a 14.6 Ah LiMn2O4 cathode/graphite

Effective Battery Design and Integration of Cylindrical Cells

Apr 14, 2021 · Abstract To fulfill the far-reaching requirements of an effective battery design for high power applications, every single component, including their interactions with the battery

How to Weld Lithium Batteries: Common Methods and

Dec 4, 2024 · Welding is a critical step in lithium battery pack assembly. The quality of the weld directly impacts the performance and lifespan of the battery pack. This guide explains

Cylindrical Cell Joining Methods

Jan 18, 2025 · Cylindrical cells are commonly joined using several methods, each with distinct advantages and disadvantages depending on the application. Here are the most popular

Design, Properties, and Manufacturing of Cylindrical Li-Ion

Jun 3, 2023 · This paper investigates 19 Li-ion cylindrical battery cells from four cell manufacturers in four formats (18650, 20700, 21700, and 4680). We aim to systematically capture the design

Effective Battery Design and Integration of Cylindrical Cells

Apr 14, 2021 · Kreisel Electric''s battery design based on cylindrical cells and immersion cooling, answers all these questions and proposes new solutions on the design and material side.

A Guide to Properly Identifying Lithium Battery

Jun 7, 2024 · Learn to identify lithium battery terminals correctly, how to match lithium battery connectors and terminals, and how to choose the right one for

Homogeneous constitutive relationship of cylindrical lithium

Jul 1, 2025 · In this study, we design a loading apparatus capable of precisely measuring the relationship between the loading distance and the contact area between the battery and the

Thermal-Runaway Propagation over a Linear Cylindrical Battery

Apr 3, 2020 · Thermal-runaway propagation in battery systems can escalate the battery fire hazard and pose a severe threat to global users. In this work, the thermal-runaway

A Structure of Cylindrical Lithium-ion Batteries

Jul 14, 2016 · Cylindrical Lithium-ion Batteries have been used in many electronic devices. The electrochemical cell of the batteries consists of a layer of positive electrode, a layer of negative

Battery Pack Design of Cylindrical Lithium-Ion Cells and

Sep 12, 2022 · lls are connected in parallel to form a battery submodule, and 13 battery submodules are connected in series to form a battery pack. The battery pack design process

A Comprehensive Guide to Cylindrical Lithium

Jul 31, 2025 · Cylindrical lithium-ion battery cells are a type of rechargeable battery commonly used in a wide range of electronic devices, electric vehicles,

6 FAQs about [Cylindrical lithium battery connection]

What is a cylindrical lithium ion battery?

Cylindrical lithium-ion battery cells are a type of rechargeable battery commonly used in a wide range of electronic devices, electric vehicles, and energy storage systems. They are characterized by their cylindrical shape, standardized sizes, and high energy density, making them versatile and suitable for various applications.

Are cylindrical lithium batteries a good choice?

Cylindrical lithium batteries are more suitable for large-volume automated combination production. Large-volume lithium-ion batteries such as electric bicycles and electric motorcycles are basically produced from cylindrical lithium batteries. Not only that, cylindrical lithium batteries are also recognized as green and healthy batteries.

How many Li-ion cylindrical battery cells are there?

This paper investigates 19 Li-ion cylindrical battery cells from four cell manufacturers in four formats (18650, 20700, 21700, and 4680). We aim to systematically capture the design features, such as tab design and quality parameters, such as manufacturing tolerances and generically describe cylindrical cells.

How to design cylindrical Li-ion battery cells?

A generic overview of designing cylindrical Li-ion battery cells. Function 1: Two types of jelly roll designs can be distinguished: With tabs and tabless. Jelly rolls with tabs can be realized with a single tab (Design A) or several tabs in a multi-tab design (Design B).

How do you identify a cylindrical lithium-ion battery?

For instance, “65” represents a height of 65mm. Fifth Digit: The fifth digit indicates the cylindrical shape of the cell. Typically, it’s “0” for cylindrical cells. By following this naming convention, we can easily identify the size and shape of cylindrical lithium-ion battery cells.

What is a cylindrical lithium battery used for?

Cylindrical lithium batteries can be used as power sources. In addition, they can also be seen in digital cameras, MP3 players, notebook computers, car starters, power tools, and other portable electronic products. Part 2. Structure of cylindrical battery

Learn More

- Ecuador nca cylindrical lithium battery

- Is the Warsaw lithium battery cylindrical

- Ethiopia cylindrical lithium battery

- Dili Large Cylindrical Lithium Battery

- What kind of cylindrical lithium battery is it

- Cylindrical lithium battery diameter 25 height 65

- Lithium battery 3 6v cylindrical double

- Is the Wellington cylindrical lithium battery useful

- Madrid cylindrical lithium battery

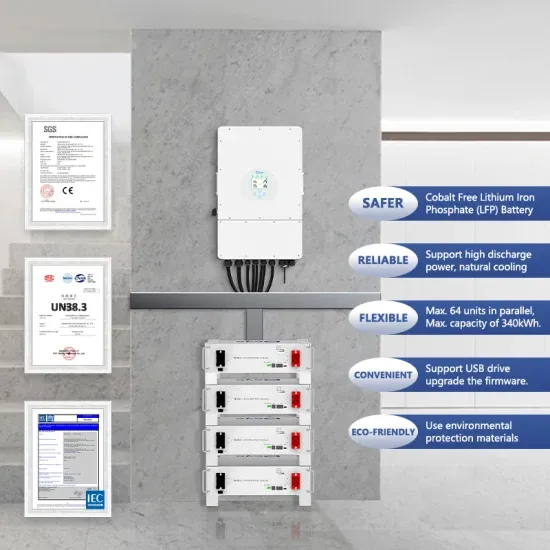

Industrial & Commercial Energy Storage Market Growth

The global industrial and commercial energy storage market is experiencing explosive growth, with demand increasing by over 250% in the past two years. Containerized energy storage solutions now account for approximately 45% of all new commercial and industrial storage deployments worldwide. North America leads with 42% market share, driven by corporate sustainability initiatives and tax incentives that reduce total project costs by 18-28%. Europe follows closely with 35% market share, where standardized industrial storage designs have cut installation timelines by 65% compared to traditional built-in-place systems. Asia-Pacific represents the fastest-growing region at 50% CAGR, with manufacturing scale reducing system prices by 20% annually. Emerging markets in Africa and Latin America are adopting industrial storage solutions for peak shaving and backup power, with typical payback periods of 2-4 years. Major commercial projects now deploy clusters of 15+ systems creating storage networks with 80+MWh capacity at costs below $270/kWh for large-scale industrial applications.

Industrial Energy System Innovations & Cost Benefits

Technological advancements are dramatically improving industrial energy storage performance while reducing costs. Next-generation battery management systems maintain optimal operating conditions with 45% less energy consumption, extending battery lifespan to 20+ years. Standardized plug-and-play designs have reduced installation costs from $85/kWh to $40/kWh since 2023. Smart integration features now allow multiple industrial systems to operate as coordinated energy networks, increasing cost savings by 30% through peak shaving and demand charge management. Safety innovations including multi-stage fire suppression and thermal runaway prevention systems have reduced insurance premiums by 35% for industrial storage projects. New modular designs enable capacity expansion through simple system additions at just $200/kWh for incremental capacity. These innovations have improved ROI significantly, with commercial and industrial projects typically achieving payback in 3-5 years depending on local electricity rates and incentive programs. Recent pricing trends show standard industrial systems (1-2MWh) starting at $330,000 and large-scale systems (3-6MWh) from $600,000, with volume discounts available for enterprise orders.