Classification of photovoltaic grid-connected inverters

Grid-connected transformerless photovoltaic (PV) inverters (TPVIs) are increasingly dominating the market due to their higher efficiency, lower cost, lighter weight, and reduced size when

Classification of photovoltaic grid-connected inverters

What are the different types of grid-connected PV inverter topologies? In the literature,different types of grid-connected PV inverter topologies are available,both single-phase and three

Review Of An Inverter For Grid Connected Photovoltaic

Oct 16, 2014 · The inverters are categorized into four classifications: 1) the number of power processing stages in cascade; 2) the type of power de-coupling between the PV module(s)

Classification and testing methods of inverters

Jun 10, 2022 · Classification of inverters There are many types of modern inverter technology, and the main classification methods are as follows. (1) According

A review of inverter topologies for single-phase grid-connected

May 1, 2017 · This review work covers the overview of single-phase grid-connected inverters including the standards and specifications of inverters, classification of inverter types, historical

Photovoltaic grid-connected inverter classification and

Feb 22, 2019 · Including isolated and non-isolated types, the isolated grid-connected inverter is divided into power frequency transformer isolation mode and high-frequency transformer

Machine learning for monitoring and classification in inverters

Mar 1, 2024 · These functions are supported by multiple subsystems within inverters - such as breakers, capacitors, heat management, ground fault detectors, power supply, and many

An inclusive review on different multi-level inverter topologies

Aug 1, 2018 · This paper presents the various MLIs, their modulation and control techniques for the grid connected applications. A detailed classification of different grid connected Multi-level

A Comprehensive Review on Multilevel Inverters

Aug 29, 2022 · Multi-level inverters (MLIs) have been widely used in recent years due to their various advantages in industrial and grid-connected applications.

Photovoltaic inverter classification and differences

Grid-tied solar systems. Grid-tied systems are solar panel installations that are connected to the utility power grid.With a grid-connected system, a home can use the solar energy produced by

What are the classifications of photovoltaic grid

Feb 10, 2022 · Therefore, mastering the photovoltaic grid-connected inverter technology plays a vital role in the application and promotion of photovoltaic

Classification of photovoltaic grid-connected

May 28, 2023 · As the name implies, the centralized inverter converts the direct current generated by photovoltaic modules into alternating current for step-up

Classification of photovoltaic grid-connected inverters

May 28, 2023 · Common classification of photovoltaic grid-connected inverters:As an important part of photovoltaic power generation, the inverter mainly converts the direct current generated

Photovoltaic grid-connected inverter classification

Grid-connected transformerless photovoltaic (PV) inverters (TPVIs) are increasingly dominating the market due to their higher efficiency, lower cost, lighter weight, and reduced size when

A Comprehensive Review on Grid Connected Photovoltaic

Aug 13, 2020 · This review article presents a comprehensive review on the grid-connected PV systems. A wide spectrum of different classifications and configurations of grid-connected

Investigations on testing and topologies of grid

Jul 12, 2021 · Global energy status of the photovoltaic industry in this paper discusses reviews and explains the Categorization of the PV system, i.e. stand-alone grid-connected topologies,

Photovoltaic grid-connected inverter classification and

Feb 22, 2019 · It is divided into two types: single-directional power flow grid-connected inverter and dual-direction power flow grid-connected inverter. The unidirectional power flow grid

A multi-level classification method for fault diagnosis of grid

May 24, 2021 · This article proposes a multi-level classification fault diagnosis method for the open-circuit fault of power semiconductor; signal-stuck, gain-variation, and zero-offset of the

Review and Classification of Control Systems in Grid-tied Inverters

May 1, 2017 · In this paper, different control systems performed on grid-connected inverters are analyzed and a review of solutions is done for the control of grid-tied inverters. These control

Supervised classification and fault detection in grid-connected

Dec 1, 2024 · The faults have been created at different locations of the 11×6 PV array in the MATLAB/Simulink platform for a better understanding of the proposed approach using I-V

A comprehensive review of grid-connected solar

Jun 1, 2023 · The various control techniques of multi-functional grid-connected solar PV inverters are reviewed comprehensively. The installed capacity of solar photovoltaic (PV) based

Fault detection and classification in hybrid energy-based

Mar 28, 2024 · Timely detection and classification of faults allow for rapid response and corrective actions to maintain grid stability. Similarly, faults within a microgrid can cause damage to

6 FAQs about [Classification of grid-connected inverters]

What are the different types of grid-connected inverters?

Aside from the modes of operation, grid-connected inverters are also classified according to configuration topology. There are four different categories under this classification. Central inverters, which are usually around several kW to 100 MW range. String inverters, typically rated around a few hundred Watts to a few kW.

What are the control systems performed on grid-connected inverters?

In this paper, different control systems performed on grid-connected inverters are analyzed and a review of solutions is done for the control of grid-tied inverters. These control systems are classified and compared as reference frame, implementation platform, output filter of inverter, control strategy, modulation method, and controller.

How are inverters classified according to interconnection types?

Inverter classification according to Interconnection types is discussed in EME 812 (11.4. Grid connection and role of inverters). Aside from the modes of operation, grid-connected inverters are also classified according to configuration topology. There are four different categories under this classification.

How are inverters classified?

Inverters are classified based on their size, mode of operation, or configuration topology. Considering the classification based on the mode of operation, inverters can be classified into three broad categories: Inverter classification according to Interconnection types is discussed in EME 812 (11.4. Grid connection and role of inverters).

How to classify multi-level grid-connected inverters based on power circuit structure?

Classification of multi-level grid-connected inverters based on power circuit structure. 4.1. Neutral Point Clamped GCMLI (NPC-GCMLI) ]. For generalized -level, ]. In this topology, two conventional VSIs (2-level inverters) ar e stacked over one another. The positive point of lower inverter and negative point of upper inverter are

What are the topologies of multi-level grid-connected inverters?

topologies are NPC-GCMLI, FC-GCMLI, CHB-GCMLI, and M-GCMLI . Therefore, in this section presented schematically. Figure 5. Classification of multi-level grid-connected inverters based on power circuit structure. Figure 5. Classification of multi-level grid-connected inverters based on power circuit structure. 4.1.

Learn More

- Huawei has photovoltaic grid-connected inverters

- Can micro grid-connected inverters be used

- Temperature and humidity requirements for grid-connected inverters for communication base stations

- Grid-connected inverters are integrated into off-grid systems

- Multiple input voltages for grid-connected inverters

- Photovoltaic panels and inverters

- Photovoltaic inverters use more electricity

- Budapest export solar inverters

- Wholesale household inverters in Pretoria

Industrial & Commercial Energy Storage Market Growth

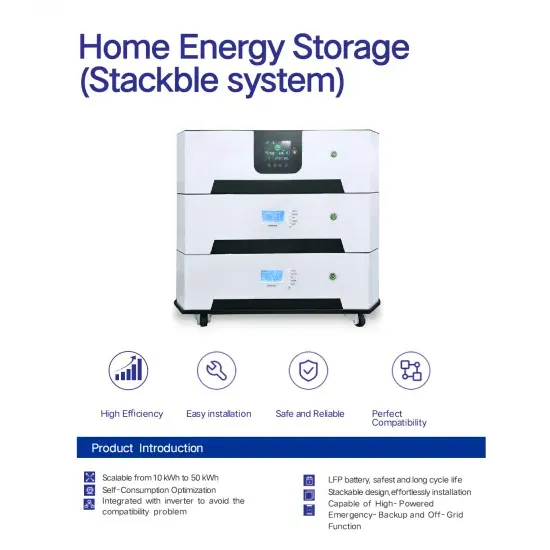

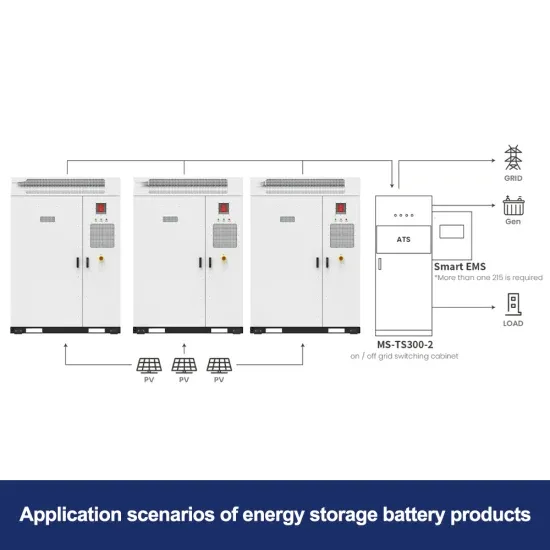

The global industrial and commercial energy storage market is experiencing explosive growth, with demand increasing by over 250% in the past two years. Containerized energy storage solutions now account for approximately 45% of all new commercial and industrial storage deployments worldwide. North America leads with 42% market share, driven by corporate sustainability initiatives and tax incentives that reduce total project costs by 18-28%. Europe follows closely with 35% market share, where standardized industrial storage designs have cut installation timelines by 65% compared to traditional built-in-place systems. Asia-Pacific represents the fastest-growing region at 50% CAGR, with manufacturing scale reducing system prices by 20% annually. Emerging markets in Africa and Latin America are adopting industrial storage solutions for peak shaving and backup power, with typical payback periods of 2-4 years. Major commercial projects now deploy clusters of 15+ systems creating storage networks with 80+MWh capacity at costs below $270/kWh for large-scale industrial applications.

Industrial Energy System Innovations & Cost Benefits

Technological advancements are dramatically improving industrial energy storage performance while reducing costs. Next-generation battery management systems maintain optimal operating conditions with 45% less energy consumption, extending battery lifespan to 20+ years. Standardized plug-and-play designs have reduced installation costs from $85/kWh to $40/kWh since 2023. Smart integration features now allow multiple industrial systems to operate as coordinated energy networks, increasing cost savings by 30% through peak shaving and demand charge management. Safety innovations including multi-stage fire suppression and thermal runaway prevention systems have reduced insurance premiums by 35% for industrial storage projects. New modular designs enable capacity expansion through simple system additions at just $200/kWh for incremental capacity. These innovations have improved ROI significantly, with commercial and industrial projects typically achieving payback in 3-5 years depending on local electricity rates and incentive programs. Recent pricing trends show standard industrial systems (1-2MWh) starting at $330,000 and large-scale systems (3-6MWh) from $600,000, with volume discounts available for enterprise orders.