What Is A 12V Inverter And Where Is It Used?

May 26, 2025 · A 12V inverter is a device that converts 12V DC power from batteries or solar panels into 120V/230V AC electricity, enabling the use of household appliances in off-grid or

Can you run 12V system from 24V battery pack

Feb 4, 2023 · Thank You Sounds like simplest is to just use a 12V inverter so I can use lights without having to power-up the inverter. Depends on the size of the inverter and usage. On 12

5 Things You Need to Know About 12V Inverters | L&T-SuFin

Apr 4, 2023 · A 12V inverter is a device that transforms 12V battery power from direct current (DC) to alternating current (AC). This AC power is used to operate various electrical devices. 12V

12V Inverter vs 24V Inverter — What Is The

Dec 11, 2024 · This article will explore the differences between 12v inverter vs 24v inverter, considering factors such as energy loss, battery requirements, and

Can I Use a 24V Inverter with a 12V Battery? Compatibility

Feb 7, 2025 · To use a 24V inverter with a 12V battery, you can connect two 12V batteries in series. Connecting batteries in series effectively doubles the voltage, providing 24 volts to the

Exploring the Best 12V Power Inverters: A

Apr 14, 2025 · At its core, a 12V power inverter is a device that converts direct current (DC) from a car battery into alternating current (AC), which is required

What does a power inverter do, and what can I use one for?

The inverter draws its power from a 12 Volt battery (preferably deep-cycle), or several batteries wired in parallel. The battery will need to be recharged as the power is drawn out of it by the

Power inverters 12v

May 24, 2025 · For RVs and ships, 12v photovoltaic inverters can use solar energy to power on-board appliances (such as car refrigerators, speakers, navigation devices, etc.) and equipment

What Size Inverter Can I Run Off a 100Ah Battery? A

Aug 13, 2024 · This capacity influences how long an inverter can run appliances before needing a recharge. However, battery capacity alone doesn''t dictate inverter size. The inverter converts

Tips to Choose the Right Inverter for Homes:

Sep 27, 2023 · Choose the Right Inverter with the difference between 12V or 24V and their advantages: inverter efficiency, battery bank setup, cabling cost, and

Power When Away From Home | Using a Power Inverter

Aug 25, 2022 · Using an inverter to generate power from a battery can be an invaluable resource for anyone who finds themselves away from traditional AC power sources. If you can, try to

Power Inverters: What Are They & How Do They

Dec 17, 2019 · It can be used as a standalone device such as solar power or back power for home appliances. The inverter takes DC power from the batteries

What size inverter do you need for a 100ah

Oct 17, 2022 · What size inverter for a 100Ah battery? For appliances that use a relatively low amount of power, such as laptops, lights, TVs, and small fridges,

6 FAQs about [What can a 12v inverter be used for]

What is a 12V DC power inverter?

This is where a power inverter comes in. Definition and Working Principle A 12V DC power inverter is a device that converts low-voltage direct current (DC) power from a 12V battery (such as a car battery or deep-cycle battery) into 120V alternating current (AC) power, making it suitable for household appliances and electronic devices.

What type of power does a power inverter use?

In many off-grid or mobile power scenarios, standard household appliances require AC (alternating current) power, but most batteries and vehicle power systems provide DC (direct current) power at 12 volts. This is where a power inverter comes in. Definition and Working Principle

What is a 12V car power inverter?

A 12V car power inverter is a must-have for road trips, mobile workstations, and emergency preparedness. It allows drivers and passengers to charge and use electronic devices directly from the vehicle's battery or cigarette lighter port. Devices Powered: Laptops, smartphones, car refrigerators, small power tools, portable gaming consoles.

What do you connect a 12 volt inverter to?

You simply connect the inverter to a 12 volt battery and plug your device into the inverter. This is a great solution for having an easy to use, portable power supply.

Why do you need a power inverter?

In remote areas or where electricity is unstable, power inverters can provide a stable AC power source for household appliances. By converting car batteries or other DC power sources, power inverters can ensure the proper functioning of household appliances such as TVs, refrigerators, and lighting.

Are 12V inverters commonly used in RVs and solar power systems?

Yes, 12V inverters are commonly used in RVs and solar power systems. When choosing an inverter for these setups, ensure that it is compatible with your battery bank and solar panel capacity. This ensures your system runs efficiently and can handle the load of various devices without issues.

Learn More

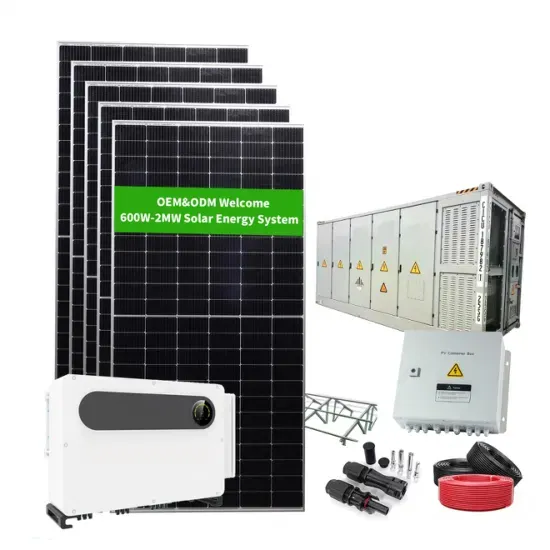

Industrial & Commercial Energy Storage Market Growth

The global industrial and commercial energy storage market is experiencing explosive growth, with demand increasing by over 250% in the past two years. Containerized energy storage solutions now account for approximately 45% of all new commercial and industrial storage deployments worldwide. North America leads with 42% market share, driven by corporate sustainability initiatives and tax incentives that reduce total project costs by 18-28%. Europe follows closely with 35% market share, where standardized industrial storage designs have cut installation timelines by 65% compared to traditional built-in-place systems. Asia-Pacific represents the fastest-growing region at 50% CAGR, with manufacturing scale reducing system prices by 20% annually. Emerging markets in Africa and Latin America are adopting industrial storage solutions for peak shaving and backup power, with typical payback periods of 2-4 years. Major commercial projects now deploy clusters of 15+ systems creating storage networks with 80+MWh capacity at costs below $270/kWh for large-scale industrial applications.

Industrial Energy System Innovations & Cost Benefits

Technological advancements are dramatically improving industrial energy storage performance while reducing costs. Next-generation battery management systems maintain optimal operating conditions with 45% less energy consumption, extending battery lifespan to 20+ years. Standardized plug-and-play designs have reduced installation costs from $85/kWh to $40/kWh since 2023. Smart integration features now allow multiple industrial systems to operate as coordinated energy networks, increasing cost savings by 30% through peak shaving and demand charge management. Safety innovations including multi-stage fire suppression and thermal runaway prevention systems have reduced insurance premiums by 35% for industrial storage projects. New modular designs enable capacity expansion through simple system additions at just $200/kWh for incremental capacity. These innovations have improved ROI significantly, with commercial and industrial projects typically achieving payback in 3-5 years depending on local electricity rates and incentive programs. Recent pricing trends show standard industrial systems (1-2MWh) starting at $330,000 and large-scale systems (3-6MWh) from $600,000, with volume discounts available for enterprise orders.