Google and Chile Launch Humboldt Cable Linking Continents

Jun 9, 2025 · The Chilean government has formalised a landmark agreement with Google to construct the first-ever subsea fibre-optic cable linking South America and Oceania. The

Hydraulic transmission system used for wind power generation

The utility model discloses a hydraulic transmission system used for wind power generation. The system comprises an oil tank, a hydraulic pump and hydraulic motors, wherein the hydraulic

Simulation of a novel wind–wave hybrid power generation system

Jan 1, 2022 · First, the working principles of the hybrid system, individual wind power generation system, and individual wave power generation system are introduced, and relevant numerical

The Role of Hydraulic Systems in Wind Power Plants

Oct 11, 2024 · 3. Energy Storage: Hydraulic systems are being explored as potential solutions for energy storage in wind power plants. By storing excess energy in hydraulic accumulators,

Wind power generation hydraulic system | Semantic Scholar

The utility model discloses a wind power generation hydraulic system comprising an oil pump, an external oil tank, a main shaft braking unit, a yaw braking unit and a safety pressure-retaining

Integrated Renewable Energy System based on IREOM

Mar 21, 2019 · Abstract: Providing energy to areas isolated from the electricity grid through the use of a smart integrated renewable energy system (SIRES) is proposed in this study for

Parameter analysis and dual-objective optimization of the hydraulic

Sep 1, 2024 · Its parameter analysis and optimization is essential, but is ignored in the previous studies. For this reason, this study established a fully-coupled mathematical model of the

Energy Storage Techniques for Hydraulic Wind Power

Nov 6, 2015 · Abstract__ Hydraulic wind power transfer systems allow collecting of energy from multiple wind turbines into one generation unit. They bring the advantage of eliminating the

Hydraulic Wind Power Plants: A Nonlinear Model of Low Wind

Jan 21, 2016 · Nonlinear state-space representation of the hydraulic wind energy transfer is presented and validated by experimental implementations. The structure of hydraulic wind

Présentation PowerPoint

Aug 25, 2018 · The National Electric System of Chile, includes the installations for electrical generation, transmission and consumption encompassing the territory from the regions of

Hydraulic transmission system used for wind power generation

The hydraulic transmission system has the advantages of being relatively simple, low in cost and fault rate, high in power collection rate and operation performance, good in constancy in

Assessment of wind energy potential in Chile: A project

Oct 1, 2016 · The increase of wind power penetration requires providing adequate and sufficient reserves to the system, compensating for the additional intermittency and uncertainty

Designing Hydraulic Systems for Wind Turbines

In the rapidly evolving field of wind electric power generation, the role of a Wind Turbine Mechanical Engineer is crucial. One of the key responsibilities of these engineers is designing

Application and analysis of hydraulic wind power generation

Jul 1, 2023 · The development of green energy affects the development of the world. This paper analyzes the application of hydraulic wind power generation technology, clarifies its

A review of energy storage technologies in hydraulic wind

Jul 15, 2022 · This article mainly reviews the energy storage technology used in hydraulic wind power and summarizes the energy transmission and reuse principles of hydraulic

Wind Power-Energy Technology-Shanghai Lixin Hydraulics

Hengli has undergone several reliability tests to ensure the ultra-durable reliability of hydraulic cylinders, which have a longer service life, and help every wind power project to operate more

Hydraulic Wind Turbine Systems | Nature Research Intelligence

Jun 11, 2025 · Hydraulic wind turbine systems represent a novel approach to wind energy conversion that replaces conventional gearbox-based drivetrains with hydraulic transmissions.

The Role of Hydraulic Systems in Wind Power Plants

Oct 11, 2024 · Hydraulic systems play a crucial role in the operation and efficiency of these plants. This essay delves into the various aspects of hydraulic systems in wind power plants,

Winds of Change: Hydraulic Turbines Generate

May 9, 2022 · With over 50% of all hydraulic system issues tied to contamination, focusing on its control with desiccant breathers and offline filtration is a

6 FAQs about [Hydraulic system for wind power generation in Valparaiso Chile]

How hydraulic technology is applied in wind energy?

With the development of hydraulic components and the growing size of wind power generation, hydraulic technology has gradually been applied in wind energy, such as the hydraulic pitch system 2 listed in Table 1, the hydraulic braking system, 3 and hydraulic transmission system 4, 5 depicted in Table 2.

Who is developing a wind power project in Chile?

The power project is being developed by Colbun, a utility company in Chile. Credit: Hitachi Energy. The construction for an expansion to 996MW is estimated to begin in H2 2025. Credit: Thorsten schier via Shutterstock. The 816MW Horizonte wind power project is located in the Antofagasta region of Chile. Credit: FairWind.

Can hydraulic wind power system improve the utilization rate of wind energy?

Hydraulic wind power system with multi-fan and multi-generator combined operation, and the application of digital hydraulic technology can help to improve the utilization rate of wind energy and increase the power generation, which is a worthy research direction.

What is hydraulic wind turbine?

Hydraulic wind turbine uses hydraulic transmission system to replace the large-volume and large-mass gearbox and post-processing equipment, such as converter and frequency converter. Power generation quality is further improved by flexible transmission, and there are also advantages in terms of construction cost.

What does the Horizonte wind farm mean for Chile?

The Horizonte wind farm marks a significant step forward for Chile in reaching its goal of sourcing 70% of electricity from renewable sources by 2030. The project is poised to enhance regional wind power generation capacity by 70%.

What is a hybrid wind power generation system?

The hybrid configuration applies the combination of mechanical transmission and hydraulic transmission to the wind power generation system with the high efficiency of mechanical transmission and the flexibility of hydraulic transmission.

Learn More

- Uninterruptible Power Supply in Valparaiso Chile

- Wind power generation system and generator set

- Havana wind and solar hybrid power generation system

- Wind power generation system for home use

- Guatemala City communication base station wind and solar hybrid power generation energy efficiency

- Wind solar diesel and energy storage integrated power generation

- What energy storage is used for wind power generation

- Burkina Faso wind power generation system

- Flywheel energy storage application in wind power generation

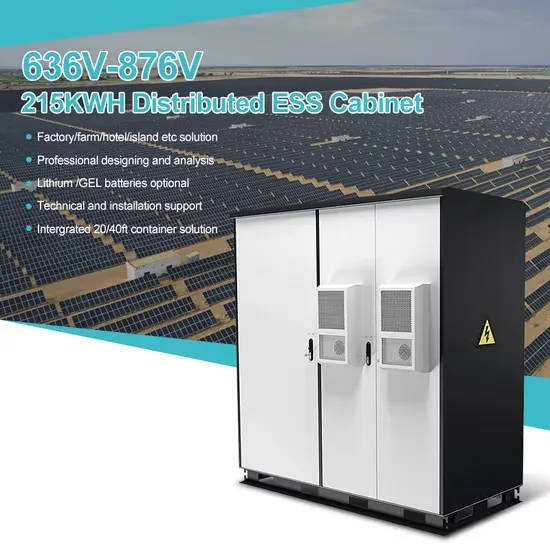

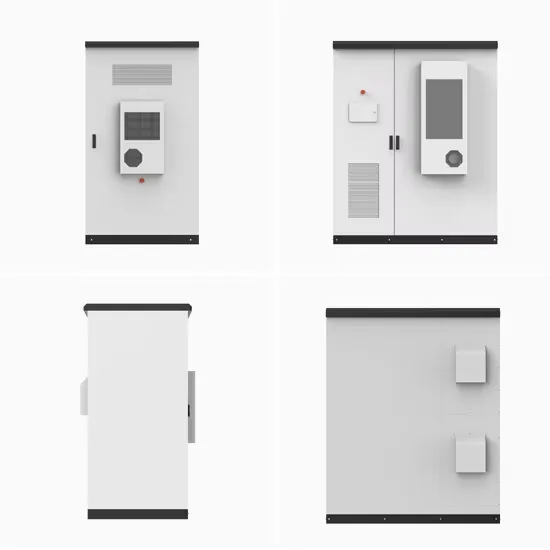

Industrial & Commercial Energy Storage Market Growth

The global industrial and commercial energy storage market is experiencing explosive growth, with demand increasing by over 250% in the past two years. Containerized energy storage solutions now account for approximately 45% of all new commercial and industrial storage deployments worldwide. North America leads with 42% market share, driven by corporate sustainability initiatives and tax incentives that reduce total project costs by 18-28%. Europe follows closely with 35% market share, where standardized industrial storage designs have cut installation timelines by 65% compared to traditional built-in-place systems. Asia-Pacific represents the fastest-growing region at 50% CAGR, with manufacturing scale reducing system prices by 20% annually. Emerging markets in Africa and Latin America are adopting industrial storage solutions for peak shaving and backup power, with typical payback periods of 2-4 years. Major commercial projects now deploy clusters of 15+ systems creating storage networks with 80+MWh capacity at costs below $270/kWh for large-scale industrial applications.

Industrial Energy System Innovations & Cost Benefits

Technological advancements are dramatically improving industrial energy storage performance while reducing costs. Next-generation battery management systems maintain optimal operating conditions with 45% less energy consumption, extending battery lifespan to 20+ years. Standardized plug-and-play designs have reduced installation costs from $85/kWh to $40/kWh since 2023. Smart integration features now allow multiple industrial systems to operate as coordinated energy networks, increasing cost savings by 30% through peak shaving and demand charge management. Safety innovations including multi-stage fire suppression and thermal runaway prevention systems have reduced insurance premiums by 35% for industrial storage projects. New modular designs enable capacity expansion through simple system additions at just $200/kWh for incremental capacity. These innovations have improved ROI significantly, with commercial and industrial projects typically achieving payback in 3-5 years depending on local electricity rates and incentive programs. Recent pricing trends show standard industrial systems (1-2MWh) starting at $330,000 and large-scale systems (3-6MWh) from $600,000, with volume discounts available for enterprise orders.