Lead acid battery production technology

Mar 15, 2024 · 1, lead-acid battery process overview Lead-acid battery is mainly composed of battery tank, battery cover, positive and negative plate, dilute sulfuric acid electrolyte, partition

Interfacing Lead Acid batteries with inverter

Apr 26, 2022 · No, inverters using lead acid only know voltage, current, temperature, and time. Some models may be better than others at guessing when an equalization charge (for FLA)

8 inverter batteries to SUPERCHARGE your home

Oct 12, 2021 · Batteries are available in different capacities and can be produced by different technologies. A 150Ah, 100Ah and 200Ah rated inverter batteries

Advantages and disadvantages of different types of

Oct 21, 2020 · The ac bus interactive inverter is an inverter/charger that can parallel battery output with generator operation and another ac source (e.g. PV array via PV inverter) to supply

Can An Inverter Damage A Battery? Risks, Safety Concerns,

Feb 8, 2025 · An inverter can damage a battery if used incorrectly. Key factors include installation quality, compatibility with the battery type, and maintenance. To minimize risks, ensure proper

Battery Room Ventilation and Safety

Mar 15, 2023 · BATTERY ROOM VENTILATION AND SAFETY It is common knowledge that lead-acid batteries release hydrogen gas that can be potentially explosive. The battery rooms

Principle, Advantage & Disadvantage of Lead

Aug 5, 2024 · Abstract Lead-acid battery is a device that converts electrical energy into direct current electricity. It is also known as storage batteries and has wide applications in

Battery Choices for Home Power Inverters: What

Sep 19, 2024 · Explore the different types of batteries (lead-acid, lithium-ion, etc.) used with home power inverters. Discuss the pros and cons of each type, their

How Do Lead Acid Inverter Batteries Work? A Simple

Jul 20, 2024 · By understanding how lead acid inverter batteries work and choosing the right brand like Sarex, you can ensure that you''re always prepared for any power interruptions. Stay

Complete Guide to Inverter Batteries – NPP POWER

Oct 23, 2024 · Inverter batteries is a rechargeable battery built to supply backup power for inverters, which convert direct current (DC) into alternating current (AC). These batteries store

Lead batteries for utility energy storage: A review

Feb 1, 2018 · Lead is the most efficiently recycled commodity metal and lead batteries are the only battery energy storage system that is almost completely recycled, with over 99% of lead

Lead Acid Battery Monitoring Implementation for

The bq34z110 uses the impedance track technique to accurately predict a battery''s SoC and SoH. Using this device helps extend battery lifetime by giving us relevant information that

From Lead-Acid to Lithium-Ion, the Diverse

Feb 18, 2025 · Lead-acid is cheap and readily available but has a drastically lower energy density than lithium-type batteries. Still, for now, its low cost wins

Inverter Battery Manufacturing Technology and Advantages

Feb 17, 2025 · From ensuring uninterrupted power supply and voltage regulation to enabling energy storage and management, inverter batteries are essential in various applications. The

From Plates to Power: Unveiling the Construction of Lead Acid Inverter

Jun 24, 2025 · What is a Lead Acid Inverter Battery? A Lead Acid inverter battery is a rechargeable battery that stores electrical energy through a chemical reaction between lead

Understanding Different Types of Lead-Acid Batteries: SLA,

Nov 12, 2024 · Discover the key differences between SLA, VRLA & AGM batteries. Learn about the performance, lifespan, maintenance & applications of lead-acid batteries in this

Amp Hour Calculator | Battery Capacity Calculator, Ah↔Wh

Amp-Hour & Battery Capacity Calculator (Epoch Model Preload) Size your battery bank and estimate runtime. Supports LiFePO 4 and lead-acid, with inverter efficiency, depth-of

LEAD ACID BATTERY

Nov 16, 2019 · Lead Acid Storage Batteries is an electro-chemical system that converts electrical energy into direct current electricity. It is also known as storage batteries and has wide

JETIR Research Journal

Feb 24, 2025 · Lead-acid batteries are among the most widely used energy storage solutions in home inverters due to their affordability, reliability, and ability to handle high surge currents.

Top 10 Lead acid battery manufacturers in India 2024

Overview of Lento Tubular Battery 200Ah- Lento flooded lead acid batteries are environment-friendly, highly reliable in performance and are low in cost. Here again our extensive research

6 FAQs about [Inverter produced by lead-acid battery]

Why is lead acid battery manufacturing difficult?

Lead acid battery manufacturing is tricky due to the intrinsic properties of the lead castings. Closed-loop DC inverters make consistent welds.

Do EVs still use a lead acid battery?

Everyone is talking about Li-ion batteries – the proverbial “belle of the ball” in the booming EV market. But did you know that most EV’s still use a traditional lead acid battery to power the car’s electronics at startup?

Are lead acid batteries reliable?

And that means lead acid batteries aren’t either! The assembly of reliable, high-performance lead-acid batteries for use in automotive, marine and industrial applications, however, poses a significant challenge. The basic application involves welding a series of lead castings or “tombstones” which make up the cores of the individual battery cells.

Are lead acid batteries going away?

Gas powered cars with internal combustion engines still make up 90+% of the worldwide market; they aren’t going away anytime soon. And that means lead acid batteries aren’t either! The assembly of reliable, high-performance lead-acid batteries for use in automotive, marine and industrial applications, however, poses a significant challenge.

Do inverter/Chargers have AC inputs?

Inverter/Chargers have ac inputs for generators. BUT! They do not parallel inverter output with the generator. They are either in inverter mode or charger mode. When the generator is not operating, the inverter will convert the dc power from the battery to provide ac power to the loads. (Inverter Mode)

How does a PV inverter work?

(Inverter Mode) When the generator starts, the inverter will switch the generator ac power to the loads, and the inverter will operate in charging mode converting the generators ac power to dc power and charge the battery. (Charger mode) The PV inverter converts the dc power from the PV array to provide ac power to the ac bus.

Learn More

- 60v20a lead-acid battery inverter

- Lead-acid battery 10kW inverter

- Lead-acid battery energy storage readable voltage

- What is the ampere of the largest lead-acid energy storage battery

- Energy storage lead-acid maintenance-free battery

- Can a 60 volt inverter be connected to a 72v battery

- Can 12v lithium battery inverter be used

- San Marino integrated communication base station lead-acid battery 6 25MWh

- How much battery will be consumed by using an inverter

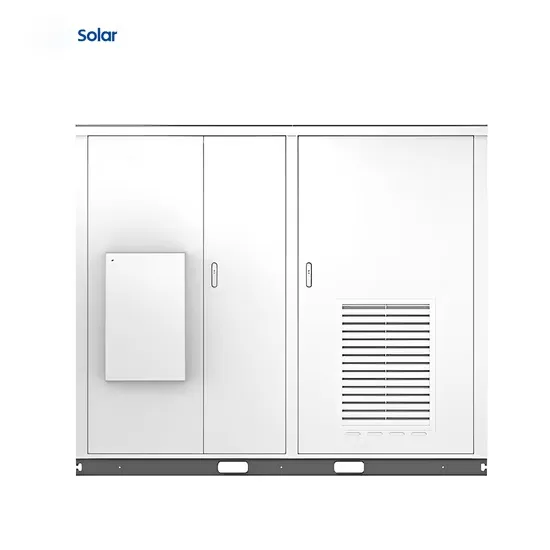

Industrial & Commercial Energy Storage Market Growth

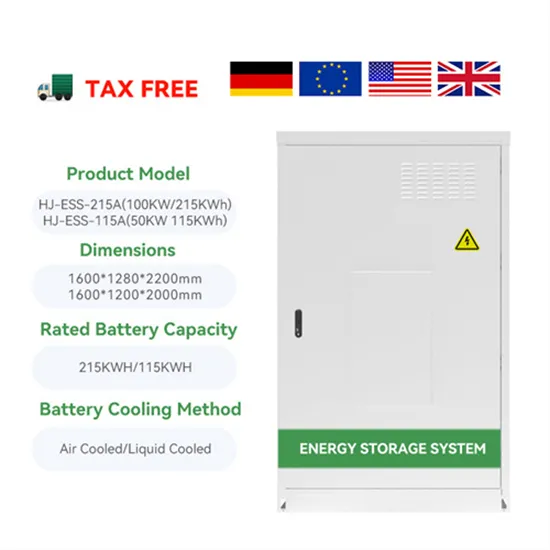

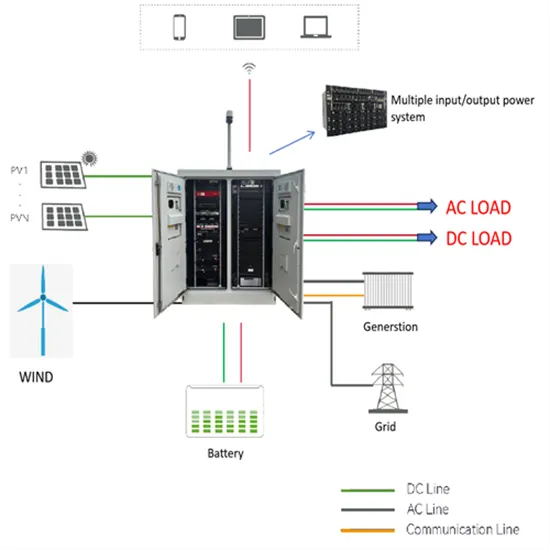

The global industrial and commercial energy storage market is experiencing explosive growth, with demand increasing by over 250% in the past two years. Containerized energy storage solutions now account for approximately 45% of all new commercial and industrial storage deployments worldwide. North America leads with 42% market share, driven by corporate sustainability initiatives and tax incentives that reduce total project costs by 18-28%. Europe follows closely with 35% market share, where standardized industrial storage designs have cut installation timelines by 65% compared to traditional built-in-place systems. Asia-Pacific represents the fastest-growing region at 50% CAGR, with manufacturing scale reducing system prices by 20% annually. Emerging markets in Africa and Latin America are adopting industrial storage solutions for peak shaving and backup power, with typical payback periods of 2-4 years. Major commercial projects now deploy clusters of 15+ systems creating storage networks with 80+MWh capacity at costs below $270/kWh for large-scale industrial applications.

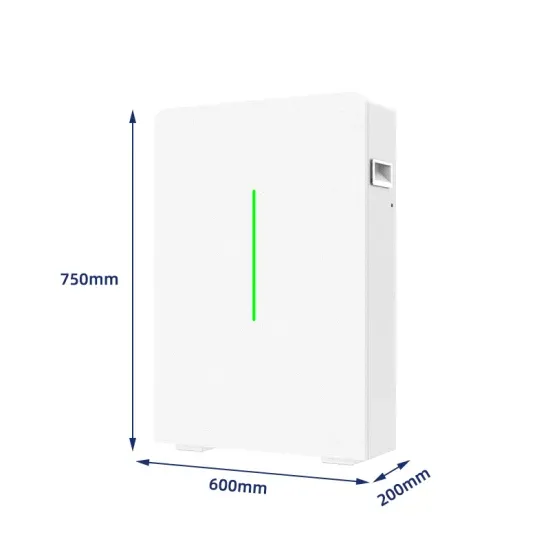

Industrial Energy System Innovations & Cost Benefits

Technological advancements are dramatically improving industrial energy storage performance while reducing costs. Next-generation battery management systems maintain optimal operating conditions with 45% less energy consumption, extending battery lifespan to 20+ years. Standardized plug-and-play designs have reduced installation costs from $85/kWh to $40/kWh since 2023. Smart integration features now allow multiple industrial systems to operate as coordinated energy networks, increasing cost savings by 30% through peak shaving and demand charge management. Safety innovations including multi-stage fire suppression and thermal runaway prevention systems have reduced insurance premiums by 35% for industrial storage projects. New modular designs enable capacity expansion through simple system additions at just $200/kWh for incremental capacity. These innovations have improved ROI significantly, with commercial and industrial projects typically achieving payback in 3-5 years depending on local electricity rates and incentive programs. Recent pricing trends show standard industrial systems (1-2MWh) starting at $330,000 and large-scale systems (3-6MWh) from $600,000, with volume discounts available for enterprise orders.