How Long Will A Car Battery Last With An Inverter? Calculate

Mar 13, 2025 · In summary, factors such as battery capacity, inverter size, load consumption, battery condition, temperature, and charging practices all play significant roles in determining

Efficiency of Inverter: Calculation & Equation Guide

Jun 22, 2022 · When only a small amount of electricity is consumed, efficiency can range from just over 50% to well over 90% when the output is approaching the inverter''s rated output. Even if

10 Tips for Using a Power Inverter Correctly

Jan 24, 2020 · Power inverter that converts DC power to AC power provides a great convenience people''s lives, especially in home appliances, such as air conditioner, refrigerator, TV, VCR,

How Long Will a Battery Last With an Inverter? (Calculator)

Jul 22, 2022 · The equation is: Battery Running Time = ( Battery Power Capacity (Wh) / Inverter Power (W) ) x Inverter Efficiency % Battery Running Time = ( 1200 Wh / 1000 W ) x

How Long Will A Car Battery Run An Inverter? Calculate

Mar 13, 2025 · A 60Ah car battery can power an inverter that requires 92.6A for about 0.65 hours. This means the battery life is approximately 39 minutes. The calculation is: Battery life =

How Much Power an Inverter Draws with No Load

To find out how much power an inverter draws without any load, multiply the battery voltage by the inverter no load current draw. A 1000 watt 24V inverter with a 0.4 no load current has a

How much energy does your inverter/BMS use?

Dec 5, 2022 · I guess this is a question more aimed at hybrid inverters. Given the poor weather for generation at the moment, the amount of energy consumed by the inverter and BMS to keep

How to calculate Inverter Battery Backup Time 2025

How Long Does Inverter Battery Last 2025-In general, you can expect your inverter battery to last anywhere around 5 to 10 hours when it is fully charged. However, you can easily calculate the

How many units of electricity does your inverter consume?

Dec 27, 2024 · Due to which electricity is used in the house. While using an inverter, a question often arises in people''s mind that how much electricity does the inverter consume. So let me

How Long Will a Car Battery Power an Inverter? Calculate

Mar 13, 2025 · What Factors Determine How Long a Car Battery Will Power an Inverter? A car battery will power an inverter for a duration dependent on several factors. Battery Capacity

Inverter Usage Calculator & Formula Online Calculator Ultra

Oct 3, 2024 · If an inverter has a power rating of 1000 watts and is used for 4 hours daily, with a battery efficiency of 85%, the energy consumption can be calculated as: [ text {Daily Energy

Does Inverter Increase Electricity Bill: Find Out

Feb 17, 2022 · Inverters are designed to store the electricity in the batteries so that you can use it whenever there is no electricity in the area. I have been using an inverter for a very long time

Do 1000W inverters use a lot of battery power?

Sep 14, 2024 · As people''s demand for mobile power increases, inverters are becoming more and more common in daily life. Whether it is RV travel, camping activities, or dealing with

How Long Can I Run The Power Inverter On My

Mar 18, 2025 · How long does an inverter that uses battery power actually last? This article will delve into this question and provide knowledge and calculations.

How Long Will A Battery Last Using An Inverter? Calculate

Mar 27, 2025 · A 12-volt, 100Ah battery can power a 1000-watt inverter load for about 1.08 hours. This estimate includes an inverter efficiency of 90%. Use this formula for quick calculations:

How many hours does an inverter battery last

In general, inverter batteries can last anywhere from 5 to 10 hours. To avail maximum benefits, invest in a battery that fits your needs, and also functions efficiently for the long run. How to

Understanding Inverter Power Consumption: Do Inverters

Mar 12, 2025 · In today''s energy-conscious world, many homeowners and businesses are increasingly turning to energy-efficient solutions, and inverters have become an essential part

Frequently Asked Questions about Inverters

Frequently Asked Questions about Inverters How much battery capacity do I need with an inverter? As a rule of thumb, the minimum required battery capacity for a 12-volt system is

How Long Will a 12V Battery Last When Using an Inverter

Mar 13, 2025 · When connected to a 500W inverter (92% efficiency), a 12V battery will run for 1.7664 hours. These are the methods for calculating battery life.

How Long Will A 12 Volt Battery Run An Inverter? Calculate

Mar 13, 2025 · A 12-volt battery''s runtime with an inverter depends on the load. A 27-watt stereo system runs for about 20 hours. A 100-watt color TV lasts around 10

What Will An Inverter Run & For How Long? (With Calculator)

Nov 17, 2023 · Calculating inverter battery backup time, following the same formula, you can estimate the battery backup duration for a 200Ah battery:

Inverter Load Calculator | Power Consumption Calculator

May 5, 2025 · Inverter Load Calculator and Power Consumption Calculator, Free online tool to select correct inverter & battery capacity for your home appliances. Get accurate results in

Inverter Run Time Calculator

Mar 27, 2025 · Key factors affecting inverter run time include: Battery capacity: Measured in watt-hours (Wh), it determines how much energy is stored. Load power: Measured in watts (W), it

6 FAQs about [How much battery will be consumed by using an inverter]

How long can a 200Ah battery run a 1kW inverter?

Battery Running Time = ( Battery Power Capacity (Wh) / Inverter Power (W) ) x Inverter Efficiency % Battery Running Time = ( 1200 Wh / 1000 W ) x 95% Battery Running Time = 1.14 Hours or 1 Hour and 8 Minutes So, a 200Ah 12V lead acid battery with 50% DOD could power a 1kW inverter with 95% efficiency at maximum load for 1 Hour and 8 Minutes.

How long does an inverter battery last?

It is the duration of time that the inverter can supply power to appliances utilizing the battery’s stored energy. A normal inverter battery should typically provide 3-4 hours of backup time. If you reside in a location with longer or more regular power outages, target a backup time of 6-8 hours.

How to calculate inverter efficiency?

Let’s say my inverter is 1kW = 1000 W with an efficiency of 95%. The equation is: Battery Running Time = ( Battery Power Capacity (Wh) / Inverter Power (W) ) x Inverter Efficiency % Battery Running Time = ( 1200 Wh / 1000 W ) x 95% Battery Running Time = 1.14 Hours or 1 Hour and 8 Minutes

How to calculate inverter battery backup time?

For example, if your battery’s discharge rate is 10A and its capacity is 100Ah, the backup duration is estimated as follows: Backup time = battery capacity ×· discharge rate Backup time = 100Ah ×· 10A The backup time is 10 hours. Calculating inverter battery backup time is essential for maintaining uninterrupted electricity during emergencies.

How much power does a 12V inverter use?

For example: If you're running a 1500W inverter on your 12v battery with 1000 watts of total AC load. So your inverter will be consuming 83 amps (amps = watts/battery volts) from the battery for which you'll need a very thick cable. using a thin cable in this scenario can damage the inverter or you'll not be able to run your load.

How long does a 1500V inverter backup take?

For example, assuming that you have a 1500VA inverter equipped with a 12V 100Ah battery and your total load wattage is 800W, the backup duration can be estimated as follows: Backup time = (battery capacity ×· power requirement of load) ×— 0.7 Backup time = (12V ×— 100Ah ×· 800W) ×— 0.7 So, the backup time will be 1.05 hours or 63 minutes.

Learn More

- How many watts does a 400AH battery have to match an inverter

- How big a lithium battery can be used with an inverter

- How much battery loss after passing through the inverter

- How to check the inverter battery of communication base station

- How many volts inverter do I need for a 68v battery

- How big a battery should the inverter use

- How long can the inverter 12v battery last

- How big an inverter can a 24v40a battery use

- Can a 48v lithium battery be boosted to 60v using an inverter

Industrial & Commercial Energy Storage Market Growth

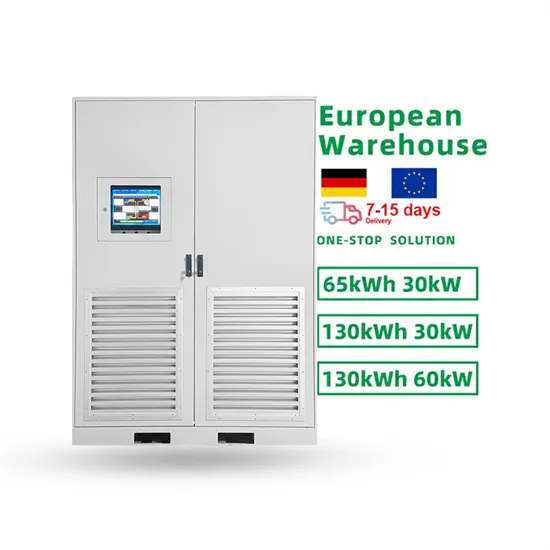

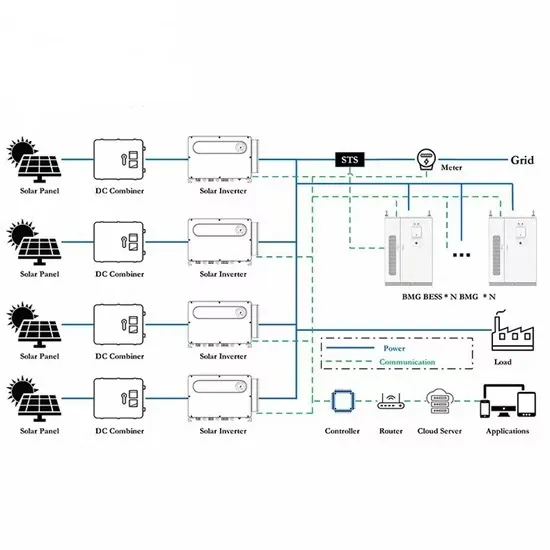

The global industrial and commercial energy storage market is experiencing explosive growth, with demand increasing by over 250% in the past two years. Containerized energy storage solutions now account for approximately 45% of all new commercial and industrial storage deployments worldwide. North America leads with 42% market share, driven by corporate sustainability initiatives and tax incentives that reduce total project costs by 18-28%. Europe follows closely with 35% market share, where standardized industrial storage designs have cut installation timelines by 65% compared to traditional built-in-place systems. Asia-Pacific represents the fastest-growing region at 50% CAGR, with manufacturing scale reducing system prices by 20% annually. Emerging markets in Africa and Latin America are adopting industrial storage solutions for peak shaving and backup power, with typical payback periods of 2-4 years. Major commercial projects now deploy clusters of 15+ systems creating storage networks with 80+MWh capacity at costs below $270/kWh for large-scale industrial applications.

Industrial Energy System Innovations & Cost Benefits

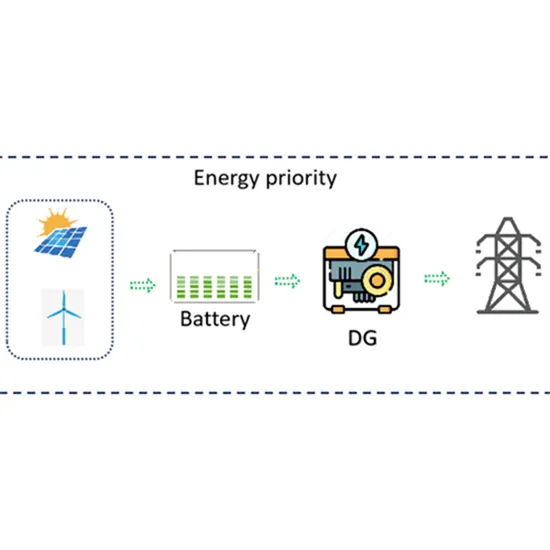

Technological advancements are dramatically improving industrial energy storage performance while reducing costs. Next-generation battery management systems maintain optimal operating conditions with 45% less energy consumption, extending battery lifespan to 20+ years. Standardized plug-and-play designs have reduced installation costs from $85/kWh to $40/kWh since 2023. Smart integration features now allow multiple industrial systems to operate as coordinated energy networks, increasing cost savings by 30% through peak shaving and demand charge management. Safety innovations including multi-stage fire suppression and thermal runaway prevention systems have reduced insurance premiums by 35% for industrial storage projects. New modular designs enable capacity expansion through simple system additions at just $200/kWh for incremental capacity. These innovations have improved ROI significantly, with commercial and industrial projects typically achieving payback in 3-5 years depending on local electricity rates and incentive programs. Recent pricing trends show standard industrial systems (1-2MWh) starting at $330,000 and large-scale systems (3-6MWh) from $600,000, with volume discounts available for enterprise orders.