Technology: Flow Battery

Nov 4, 2024 · A flow battery is an electrochemical battery, which uses liquid electrolytes stored in two tanks as its active energy storage component. For charging and discharging, these are

Go with the flow: What are flow batteries, and how do they

Jun 26, 2024 · ESS says its iron flow systems have a 25-year service life, whereas most Li-ion batteries last about 7-to-10 years. And because flow batteries store their energy in a non

What are the wind power storage batteries? | NenPower

Feb 22, 2024 · The significance of wind power storage batteries cannot be overstated, as they fundamentally reshape energy production and distribution. By allowing for energy gained

Integration of liquid air energy storage with wind power – A

Apr 1, 2024 · Batteries such as Li-ion and flow batteries feature high response speeds and flexibility, but have high costs and low lifespans [5]. Liquid air energy storage (LAES) can

Liquid Batteries as an Effective Solution for

May 13, 2025 · Thus, energy storage technologies, particularly liquid batteries, are not merely beneficial; they are essential for the advancement of renewable

Why Flow Batteries Are the Hottest Tech For

Oct 11, 2022 · A flow battery is a rechargeable battery that features electrolyte fluid flowing through the central unit from two exterior tanks. They can store

Flow Battery Basics: How Does A Flow Battery Work In

Mar 2, 2025 · What is a Flow Battery and How Does it Work in Energy Storage? A flow battery is a type of rechargeable battery that stores energy in liquid electrolytes. These electrolytes

Liquid flow batteries are rapidly penetrating into hybrid

Oct 12, 2024 · In addition to vanadium flow batteries, projects such as lithium batteries + iron-chromium flow batteries, and zinc-bromine flow batteries + lithium iron phosphate energy

Flow Batteries: The Future of Energy Storage

Feb 29, 2024 · Unlike conventional batteries, which store energy in solid electrodes, flow batteries store energy in two electrolyte solutions that flow through a cell stack. Energy Storage in

Flow Batteries: A New Energy Storage Technology for a

Jan 29, 2025 · The latest technology that will be the energy of the future is called a "flow battery." As renewable energy becomes more widespread, the need for large-scale power storage is

Lithium battery liquid cooling energy storage wind

Experimental investigations have also been conducted to validate the practical application of liquid cooling methods in BTMS. For example, Chen et al. [66] experimentally tested a double

6 FAQs about [Does wind power have liquid flow batteries ]

Are battery storage systems good for wind energy?

The synergy between wind turbines and battery storage systems is pivotal, ensuring a stable energy supply to the grid even in the absence of wind. We've looked at different batteries, including lead-acid batteries, lithium-ion, flow, and sodium-sulfur, each with its own set of applications and benefits for wind energy.

Which battery is best for a wind turbine?

Lithium-ion batteries are favoured for their high energy density and longevity, making them a robust choice for ensuring the efficiency of wind turbines. On the other hand, lead-acid batteries offer a cost-effective solution, while flow batteries stand out for their scalability and extended lifespan.

How will battery storage impact wind energy projects?

As battery prices continue to drop and their efficiency improves, integrating battery storage with wind turbines is becoming more common. This trend is likely to boost the growth of renewable energy, making the cost-effectiveness of batteries an increasingly important aspect of wind energy projects.

Are lithium-ion batteries good for wind turbines?

They've been around for a while, proving their worth in providing stable energy storage that helps smooth out the ups and downs of wind power. Lithium-ion batteries are a top choice for wind turbines, thanks to their ability to store a lot of energy in a compact space.

Can battery storage be integrated with wind turbines?

The integration of battery storage with wind turbines is a game-changer, providing a steady and reliable flow of power to the grid, regardless of wind conditions. Delving into the specifics, wind turbines commonly utilise lithium-ion, lead-acid, flow, and sodium-sulfur batteries.

Why do wind turbines use batteries?

By storing surplus energy during peak wind conditions, batteries ensure a consistent electricity supply, even when wind speeds drop. This synergy between wind turbines and batteries enhances the reliability of wind power, providing a stable, uninterrupted energy source.

Learn More

- Alexandria Egypt All-vanadium Liquid Flow Energy Storage Power Station

- Which companies produce vanadium liquid flow batteries

- 50mw all-vanadium liquid flow battery energy storage power station

- Do long-lasting liquid flow batteries work

- 100MW all-vanadium liquid flow energy storage power station

- Differences between liquid flow batteries and sodium flow batteries

- Lebanon s vanadium reserves for all-vanadium liquid flow batteries

- Armenian wind power energy storage system supplier

- Sukhumi communication base station wind power outdoor cabinet

Industrial & Commercial Energy Storage Market Growth

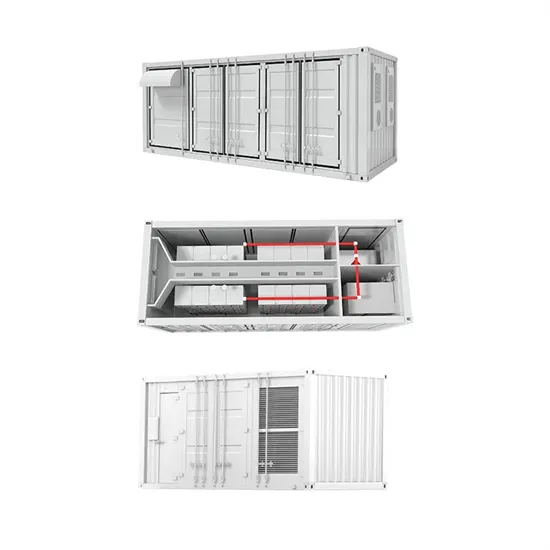

The global industrial and commercial energy storage market is experiencing explosive growth, with demand increasing by over 250% in the past two years. Containerized energy storage solutions now account for approximately 45% of all new commercial and industrial storage deployments worldwide. North America leads with 42% market share, driven by corporate sustainability initiatives and tax incentives that reduce total project costs by 18-28%. Europe follows closely with 35% market share, where standardized industrial storage designs have cut installation timelines by 65% compared to traditional built-in-place systems. Asia-Pacific represents the fastest-growing region at 50% CAGR, with manufacturing scale reducing system prices by 20% annually. Emerging markets in Africa and Latin America are adopting industrial storage solutions for peak shaving and backup power, with typical payback periods of 2-4 years. Major commercial projects now deploy clusters of 15+ systems creating storage networks with 80+MWh capacity at costs below $270/kWh for large-scale industrial applications.

Industrial Energy System Innovations & Cost Benefits

Technological advancements are dramatically improving industrial energy storage performance while reducing costs. Next-generation battery management systems maintain optimal operating conditions with 45% less energy consumption, extending battery lifespan to 20+ years. Standardized plug-and-play designs have reduced installation costs from $85/kWh to $40/kWh since 2023. Smart integration features now allow multiple industrial systems to operate as coordinated energy networks, increasing cost savings by 30% through peak shaving and demand charge management. Safety innovations including multi-stage fire suppression and thermal runaway prevention systems have reduced insurance premiums by 35% for industrial storage projects. New modular designs enable capacity expansion through simple system additions at just $200/kWh for incremental capacity. These innovations have improved ROI significantly, with commercial and industrial projects typically achieving payback in 3-5 years depending on local electricity rates and incentive programs. Recent pricing trends show standard industrial systems (1-2MWh) starting at $330,000 and large-scale systems (3-6MWh) from $600,000, with volume discounts available for enterprise orders.