Photovoltaic solar cell technologies: analysing the state of

Mar 28, 2019 · Here, we analyse the progress in cells and modules based on single-crystalline GaAs, Si, GaInP and InP, multicrystalline Si as well as thin films of polycrystalline CdTe and

What is the Difference between Thin-Film and

Mar 22, 2023 · Thin-film solar panels are lighter, thinner, and more flexible than traditional solar panels, making it easier for them to carry and install. They are

A review of thin film solar cell technologies and challenges

Apr 1, 2017 · CIGS and CdTe hold the greatest promise for the future of thin film. Longevity, reliability, consumer confidence and greater investments must be established before thin film

Thin-film Solar Overview | Cost, types, application, efficiency

Aug 25, 2019 · The structure and function of thin-film solar cells are closely linked with any standard solar cells. It means the basic science behind thin-film solar cells is the same as

3 Main Types of Solar Panels Explained 2025: How to Choose

If you''re after flexibility, thin-film solar panels are worth considering. Instead of rigid silicon wafers, these panels use a thin layer of photovoltaic material applied to surfaces like glass, plastic, or

Explained: Breaking Down the Solar Panel Triad –

Apr 25, 2025 · As solar energy adoption accelerates globally, understanding the differences between solar panel technologies is crucial for making informed decisions. The three primary

Different types of Solar Panels: Monocrystalline, Polycrystalline, Thin

Feb 5, 2024 · Discover the differences between monocrystalline, polycrystalline, thin-film, bifacial, concentrated PV, and building-integrated solar panels. Learn about their efficiency, cost,

Types of Solar Panels Explained: Monocrystalline vs.

Jun 7, 2025 · Overview Thin-film panels are made by depositing photovoltaic material in thin layers onto a substrate like glass, plastic, or metal. They are lightweight and flexible in design.

Crystalline Silicon Solar Cell

On the other hand, the mono-Si is comprised of a continuous crystal without grain boundaries [70,72]. As a result, the mono-Si or single-crystal silicon is believed to have higher efficiency

Polycrystalline Thin-Film Research: Cadmium Telluride

Jun 2, 2025 · Polycrystalline Thin-Film Research: Cadmium Telluride Cadmium telluride (CdTe) photovoltaic (PV) research has enabled costs to decline significantly, making this technology

Monocrystalline, Polycrystalline, and Thin-Film

3 days ago · Thin-Film Solar Panels Thin-film panels are constructed from ultra-thin layers of photovoltaic materials, such as cadmium telluride or amorphous

Thin-film solar and single-crystal solar, which is better?

Jun 16, 2024 · Thin-film solar gathers praise for its versatility and cost-effectiveness, making it an attractive choice for projects with flexibility and budget constraints. Yet, single-crystal

Solar Panels: Thin Film or Crystalline

In thin film, the semiconductor material is generally copper indium diselenide or cadmium telluride, although they can also be produced using thin film silicon. The biggest boon to using thin film

Photovoltaic (PV) Cell Types | Monocrystalline,

5 days ago · The article provides an overview of the main types of photovoltaic (PV) cells, including monocrystalline, polycrystalline, and thin-film solar

Thin Film Solar Panels: What You Need to Know – Solair World

Types of Thin Flim Solar Panel Traditional solar panels are made from silicon that''s arranged in a crystal form, called c-Si. These panels have small solar cells that are either cut from a single

6 FAQs about [Photovoltaic thin film or single crystal panel]

Are thin-film solar panels better than crystalline solar panels?

Thin-film solar panels are lighter, thinner, and more flexible than traditional solar panels, making it easier for them to carry and install. They are also less expensive than standard solar panels due to the less complex production process. They are more durable than crystalline panels because they have lower temperature coefficients.

What are thin film solar panels?

An examination of thin film solar panels reveals a photovoltaic technology that utilizes thin layers of semiconducting materials to convert sunlight into electricity. Unlike traditional crystalline solar panels, thin film solar panels are flexible, lightweight, and can be manufactured in a variety of shapes and sizes.

Are c-Si solar panels better than thin film solar panels?

Crystalline silicon panels are also more cost-efficient than thin film technology currently, requiring a lower production process to complete. A c-SI solar panel is more environmentally friendly than a thin film PV panel as it contains no harmful materials that thin film silicon cells may have.

What are crystalline solar panels?

Crystalline solar panels are classified into two types: monocrystalline and polycrystalline. Monocrystalline panels are made from a single crystal of silicon and are more efficient than polycrystalline panels which are made from multiple crystals of silicon.

Why are thin layer solar panels better than crystalline solar panels?

Thin layer solar panels are also ideal for space use due to their high efficiency semiconductor material and radiation tolerance. Modern panels also have lower temperature coefficients than crystalline panels, offering durability as a trade for its pricing.

Are thin film solar panels a good investment?

Thin film panels are starting to bridge the price gap by replacing silicon with other rare materials like cadmium and indium and offer more flexibility and portability. Thin layer solar panels are also ideal for space use due to their high efficiency semiconductor material and radiation tolerance.

Learn More

- What is the size of a single crystal 400w photovoltaic panel

- Photovoltaic panel single crystal power generation

- Color difference of single crystal photovoltaic panels

- Northern Cyprus photovoltaic carbon crystal panel manufacturer

- Use of single crystal photovoltaic panels

- Commercial single crystal double glass photovoltaic panels

- Single column photovoltaic panel specifications

- Lithuanian thin film solar photovoltaic panel manufacturer

- Somalia thin film photovoltaic panel size

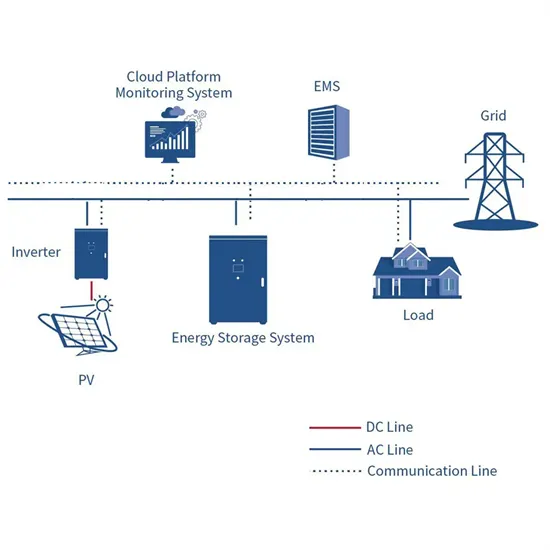

Industrial & Commercial Energy Storage Market Growth

The global industrial and commercial energy storage market is experiencing explosive growth, with demand increasing by over 250% in the past two years. Containerized energy storage solutions now account for approximately 45% of all new commercial and industrial storage deployments worldwide. North America leads with 42% market share, driven by corporate sustainability initiatives and tax incentives that reduce total project costs by 18-28%. Europe follows closely with 35% market share, where standardized industrial storage designs have cut installation timelines by 65% compared to traditional built-in-place systems. Asia-Pacific represents the fastest-growing region at 50% CAGR, with manufacturing scale reducing system prices by 20% annually. Emerging markets in Africa and Latin America are adopting industrial storage solutions for peak shaving and backup power, with typical payback periods of 2-4 years. Major commercial projects now deploy clusters of 15+ systems creating storage networks with 80+MWh capacity at costs below $270/kWh for large-scale industrial applications.

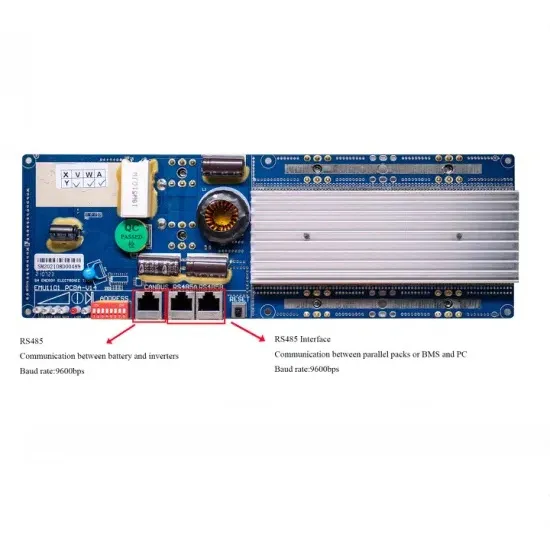

Industrial Energy System Innovations & Cost Benefits

Technological advancements are dramatically improving industrial energy storage performance while reducing costs. Next-generation battery management systems maintain optimal operating conditions with 45% less energy consumption, extending battery lifespan to 20+ years. Standardized plug-and-play designs have reduced installation costs from $85/kWh to $40/kWh since 2023. Smart integration features now allow multiple industrial systems to operate as coordinated energy networks, increasing cost savings by 30% through peak shaving and demand charge management. Safety innovations including multi-stage fire suppression and thermal runaway prevention systems have reduced insurance premiums by 35% for industrial storage projects. New modular designs enable capacity expansion through simple system additions at just $200/kWh for incremental capacity. These innovations have improved ROI significantly, with commercial and industrial projects typically achieving payback in 3-5 years depending on local electricity rates and incentive programs. Recent pricing trends show standard industrial systems (1-2MWh) starting at $330,000 and large-scale systems (3-6MWh) from $600,000, with volume discounts available for enterprise orders.