The 9 Types of Solar Panels in the UK | 2025

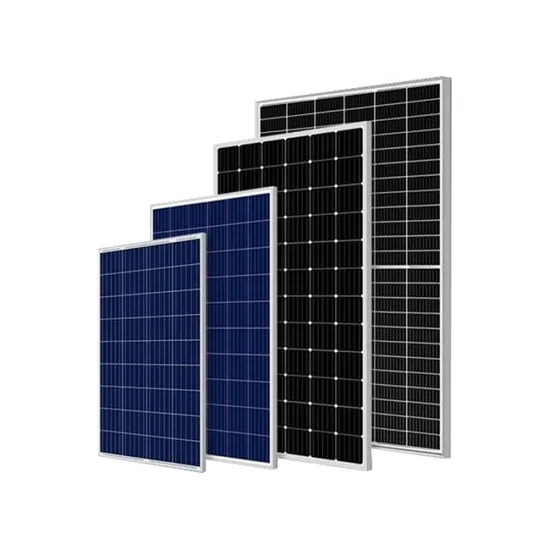

Jun 3, 2025 · Their greater efficiency lies in their single-crystal silicon structure, which is capable of capturing more sunlight into electricity than alternatives

Types of photovoltaic solar panels and their

Nov 6, 2017 · Instead of using silicon in crystalline form, they use a thin layer of photovoltaic material deposited on a substrate such as glass, plastic or metal.

Twenty years crystal growth of solar silicon: My serendipity

Jan 15, 2024 · The development of the PV industry is a vigorous competition between mono- and multi-crystalline silicon, as well as their crystal growth technologies, which will be focused on

Understanding the Composition of Solar Panels

Apr 7, 2023 · Solar panels are composed of silicon solar cells, which convert the energy from sunlight into usable electricity. Monocrystalline cells are the most

Why Monocrystalline Silicon PV Panels Are the Best Choice

Sep 29, 2024 · Monocrystalline silicon PV panels, commonly known as single-crystal panels, are generally considered the best option for solar energy systems due to their superior efficiency,

The role and use photovoltaic panels

Monocrystalline solar panels have black-colored solar cells made of a single silicon crystal and usually have a higher efficiency rating. However, these panels often come at a higher price.

Silicon-based photovoltaic solar cells

Jan 1, 2012 · The dominant contributor to PV energy generation capacity, at present and for the foreseeable future, is silicon-based technology; in particular, crystalline (c-Si) and

Single crystal photovoltaic panel and polycrystalline

Monocrystalline (mono) panels use a single silicon crystal, while polycrystalline (poly) panels use multiple crystals melted together. Here''s a breakdown of how each type of cell is made. Mono

Single Crystal Solar Panels vs. Polycrystalline & Thin-Film:

Let''s cut through the solar jargon. When we talk about single crystal solar panels, we''re discussing the Ferraris of photovoltaic technology. These panels use silicon grown from a

What is the difference between mono-crystalline

Jun 22, 2018 · As a first time buyer of solar lights, we might get confused over which solar panels to go for. There are mainly 2 variations which you can

Types of solar cells: description of photovoltaic

Feb 12, 2016 · Photovoltaic solar panels are made up of different types of solar cells, which are the elements that generate electricity from solar energy. The

Monocrystalline Solar Panels: 2025 Costs & How

Jun 16, 2025 · Monocrystalline solar panels are the top choice for homeowners looking for high efficiency and long-term value. Made from a single crystal of

Monocrystalline photovoltaic panels: what they are and their

Dec 11, 2024 · Monocrystalline photovoltaic panels are at the forefront of solar technology due to their efficiency, durability and ability to generate energy even in confined spaces. They are

Polycrystalline Solar Panel: Definition, How it

Aug 12, 2024 · Polycrystalline, multicrystalline, or poly solar panels are a type of photovoltaic (PV) panel used to generate electricity from sunlight. They are

Polycrystalline Solar Panel: Features, Working Principle,

Sep 19, 2024 · PolyCrystalline or MultiCrystalline solar panels are solar panels that consist of several crystals of silicon in a single PV cell. Several fragments of silicon are melted together

Monocrystalline solar panels: a comprehensive guide

Aug 30, 2024 · The monocrystalline panel represents one of the most advanced technologies in the field of solar panels. Its main characteristic lies in the use of a single silicon crystal, hence

Exploring Monocrystalline Solar Panels: A Comprehensive

Nov 9, 2023 · Monocrystalline solar panels, also known as single crystalline solar panels, are made from a single continuous crystal structure. These panels are manufactured using high

Monocrystalline solar panels – Uses, Benefits and Drawbacks

Apr 17, 2024 · Key Takeaway: Monocrystalline solar panels offer superior efficiency and longevity compared to other types of solar panels, making them a prime choice for those seeking to

What are photovoltaic cells?: types and applications

Dec 17, 2024 · Photovoltaic cells, integrated into solar panels, allow electricity to be generated by harnessing the sunlight. These panels are installed on roofs, building surfaces, and land,

6 FAQs about [Use of single crystal photovoltaic panels]

Is a monocrystalline solar panel a photovoltaic module?

Yes, a monocrystalline solar panel is a photovoltaic module. Photovoltaic (PV) modules are made from semiconducting materials that convert sunlight into electrical energy. Monocrystalline solar panels are a type of photovoltaic module that use a single crystal high purity silicon cell to harness solar power.

What is a polycrystalline solar panel?

Polycrystalline solar panels are made of numerous silicon crystals, whereas thin-film solar panels are made of photovoltaic material layers. Monocrystalline solar panels are created by developing a single crystal of silicon in a cylindrical form. This material is then cut into narrow wafers, from which solar cells are made.

Are monocrystalline solar panels a good choice?

Lastly, monocrystalline panels are prevalent in premium, off-grid setups like recreational vehicles, yachts, and secluded cabins, where the availability of space for solar installations is limited and the need for high efficiency is paramount. What Factors Affect the Price of Monocrystalline Solar Panels?

What is the efficiency of a monocrystalline photovoltaic (PV) panel?

With an efficiency rate of up to 25%, monocrystalline panels reach higher efficiency levels than both polycrystalline (13-16%) and thin-film (7-18%) panels. Monocrystalline photovoltaic (PV) cells are made from a single crystal of highly pure silicon, generally crystalline silicon (c-Si).

How are monocrystalline solar panels made?

Monocrystalline solar panels are created by developing a single crystal of silicon in a cylindrical form. This material is then cut into narrow wafers, from which solar cells are made. The wafers are then coated with an anti-reflective layer before being wired together to create a solar screen.

What is a monocrystalline photovoltaic (PV) cell?

Monocrystalline photovoltaic (PV) cells are made from a single crystal of highly pure silicon, generally crystalline silicon (c-Si). Monocrystalline cells were first developed in the 1950s as first-generation solar cells. The process for making monocrystalline is called the Czochralski process and dates back to 1916.

Learn More

- Color difference of single crystal photovoltaic panels

- Commercial single crystal double glass photovoltaic panels

- The difference between single glass and double glass panels for photovoltaic panels

- Practical solar photovoltaic panels for home use

- Rainproof photovoltaic panels for home use

- Can photovoltaic solar panels be retrofitted for home use

- New house solar photovoltaic panels for home use

- How many solar photovoltaic panels are enough for home use

- Multiple solar photovoltaic panels converted to 220v home use complete set

Industrial & Commercial Energy Storage Market Growth

The global industrial and commercial energy storage market is experiencing explosive growth, with demand increasing by over 250% in the past two years. Containerized energy storage solutions now account for approximately 45% of all new commercial and industrial storage deployments worldwide. North America leads with 42% market share, driven by corporate sustainability initiatives and tax incentives that reduce total project costs by 18-28%. Europe follows closely with 35% market share, where standardized industrial storage designs have cut installation timelines by 65% compared to traditional built-in-place systems. Asia-Pacific represents the fastest-growing region at 50% CAGR, with manufacturing scale reducing system prices by 20% annually. Emerging markets in Africa and Latin America are adopting industrial storage solutions for peak shaving and backup power, with typical payback periods of 2-4 years. Major commercial projects now deploy clusters of 15+ systems creating storage networks with 80+MWh capacity at costs below $270/kWh for large-scale industrial applications.

Industrial Energy System Innovations & Cost Benefits

Technological advancements are dramatically improving industrial energy storage performance while reducing costs. Next-generation battery management systems maintain optimal operating conditions with 45% less energy consumption, extending battery lifespan to 20+ years. Standardized plug-and-play designs have reduced installation costs from $85/kWh to $40/kWh since 2023. Smart integration features now allow multiple industrial systems to operate as coordinated energy networks, increasing cost savings by 30% through peak shaving and demand charge management. Safety innovations including multi-stage fire suppression and thermal runaway prevention systems have reduced insurance premiums by 35% for industrial storage projects. New modular designs enable capacity expansion through simple system additions at just $200/kWh for incremental capacity. These innovations have improved ROI significantly, with commercial and industrial projects typically achieving payback in 3-5 years depending on local electricity rates and incentive programs. Recent pricing trends show standard industrial systems (1-2MWh) starting at $330,000 and large-scale systems (3-6MWh) from $600,000, with volume discounts available for enterprise orders.