Internal structure of solar PV modules: (a) crystalline silicon

The thin-film PV module has a completely different physical internal structure in comparison to the c-Si. Therefore, the effect of partial shading on both technologies also varies.

Fab & criteria for thin-film and crystalline

May 21, 2024 · a photovoltaic solar cell is a difficult feat of technology in execution. The challenge of balancing cell structure design, material optimization and module technology to achieve

The Structural Behaviour of PTFE/Glass Fabric Structures

Apr 29, 2020 · The velcro layer is the key solution to the targeted replaceable use of modules and is finally adhered to the thin-film solar module. Fig.1. indicates the structure of the attachment

ZSW: Thin-film solar cells and modules

In 2014, the total global production of photovoltaic modules with a-Si, CdTe and CIGS absorbers amounted to 3,144 MW, which comprised 8% of the total annual production of solar modules.

Thin Film Photovoltaics

Jan 1, 2018 · Thin film technology has the answers and potential to eliminate many existing bottlenecks of c-Si photovoltaic (PV) programs experienced at different levels from module

Thin-Film Solar Panels

Feb 27, 2021 · B. How Thin-Film Solar Cells are Made? Thin-Film solar cells are by far the easiest and fastest solar panel type to manufacture. Each thin-film solar panel is made of 3 main parts:

Concept analysis of an adaptive building envelope with thin-film

May 15, 2024 · The study involves seasonal variability and two specific geographic locations. An adaptive lightweight building envelope system with integrated thin-film photovoltaic modules

Thin-film, flexible photovoltaic module

Thin-film, flexible photovoltaic module Abstract A new, large-area, thin-film, flexible photovoltaic structure is disclosed, as well as a general fabrication procedure, including a preferably roll-to

A review of thin film solar cell technologies and challenges

Apr 1, 2017 · Thin film solar cells are favorable because of their minimum material usage and rising efficiencies. The three major thin film solar cell technologies include amorphous silicon

Monocrystalline, Polycrystalline, and Thin-Film

3 days ago · Thin-Film Solar Panels Thin-film panels are constructed from ultra-thin layers of photovoltaic materials, such as cadmium telluride or amorphous

Physical Properties of EVA and PVB Encapsulant

Apr 8, 2024 · Amorphous silicon thin film photovoltaic device has superstrate structure, in which light impinges on a conducting glass comprising transparent conductive oxide and silicon

Solution-Processed Thin Film Transparent Photovoltaics:

Oct 23, 2024 · Recent advancement in solution-processed thin film transparent photovoltaics (TPVs) is summarized, including perovskites, organics, and colloidal quantum dots. Pros and

Experimental & numerical investigation and optimization on

Jul 15, 2021 · Experimental & numerical investigation and optimization on a novel flat-plate PV/T system using CdfTe thin-film solar modules of sandwich structure

Thin-Film Solar Panels: An In-Depth Guide | Types, Pros

May 13, 2021 · As shown in Fig. 1, the The thin-film PV module shows excellent power gen- Isahaya Plant has introduced a 110 kW system on the eration characteristic under high

Technical Note

Sep 11, 2020 · Introduction Crystalline modules and thin-film modules differ in structure: crystalline modules typically consist of individual square cells (Figure 1), while thin-film modules are

What are thin-film solar cells? description, and types

Sep 26, 2019 · Thin-film solar cells are the second generation of solar cells. These cells are built by depositing one or more thin layers or thin film (TF) of photovoltaic material on a substrate,

Structure of Photovoltaic (PV) Solar Panels and Types of Photovoltaic

Feb 21, 2025 · A photovoltaic module is primarily composed of photovoltaic cells, glass, a backsheet, and encapsulant films. Photovoltaic cells convert solar energy into electricity and

Review of Recent Offshore Floating Photovoltaic

Oct 31, 2024 · Flexible floating structures photovoltaic systems, when combined with amorphous silicon (a-Si) thin film PV modules, offer advantages such as

Structure and Materials of PV Modules

Nov 29, 2017 · Structure and Materials of PV Modules A crystalline silicon module must withstand various influences in order to remain functional for 25 years or even longer.

Thin-film solar cells: review of materials, technologies and

Apr 3, 2007 · The recent boom in the demand for photovoltaic modules has created a silicon supply shortage, providing an opportunity for thin-film photovoltaic modules to enter the market

Thin-Film Solar Panels

Feb 27, 2021 · Each thin-film solar panel is made of 3 main parts: Photovoltaic Material: This is the main semiconducting material and it''s the one responsible for converting sunlight into

Technical Note

Sep 11, 2020 · Crystalline modules and thin-film modules differ in structure: crystalline modules typically consist of individual square cells (Figure 1), while thin-film modules are typically made

What are monocrystalline, polycrystalline and

Aug 25, 2014 · Solar panels (or solar modules) are assemblies of individual solar cells housed within a supporting structure or frame. The solar cells (also

What is Thin Film Photovoltaic Module?

Nov 17, 2023 · Thin film photovoltaic modules or panels consist of layers of semiconductor materials like amorphous silicon, cadmium telluride, or copper indium gallium selenide. These

6 FAQs about [Photovoltaic thin film module structure]

What are thin-film solar panels?

Thin-film solar panels use a 2 nd generation technology varying from the crystalline silicon (c-Si) modules, which is the most popular technology. Thin-film solar cells (TFSC) are manufactured using a single or multiple layers of PV elements over a surface comprised of a variety of glass, plastic, or metal.

What are the different types of thin-film solar cells?

Therefore, thin-film solar cells are generally classified according to the photovoltaic material used. According to these criteria, the following types of thin-film photovoltaic cells are found. Color-sensitive solar cells (DSC) and other organic solar cells. Cadmium telluride is the most advanced thin-film technology.

What is a thin film solar cell?

What differs Thin-Film solar cells from monocrystalline and polycrystalline is that Thin-Film can be made using different materials. There are 3 types of solar Thin-Film cells: This type of Thin-Film is made from amorphous silicon (a-Si), which is a non-crystalline silicon making them much easier to produce than mono or polycrystalline solar cells.

How do thin-film solar modules differ from silicon-based technology?

The manufacture of thin-film modules therefore differs fundamentally from the manufacture of silicon-based technology. Solar modules with already interconnected cells are processed instead of individual cells. The contact surfaces, absorber and additional intermediate layers are deposited on large glass panes in integrated processes.

What is the difference between crystalline and thin-film modules?

Crystalline modules and thin-film modules differ in structure: crystalline modules typically consist of individual square cells (Figure 1), while thin-film modules are typically made up of cell strips (Figure 2), which create their characteristic pinstripe look.

What is the efficiency of a thin-film PV system?

The efficiency of the Thin-Film system varies depending on the type of PV material used in the cells but in general they tend to have efficiencies around 7% and up to 18%. It’s important to mention that while thin-film cells have less efficiency than the crystalline ones, Thin-Film, in fact, have a higher theoretical efficiency than silicon.

Learn More

- Moldova thin film photovoltaic module manufacturers

- Praia thin film photovoltaic module manufacturer

- Photovoltaic double-glass module manufacturing company

- PVDF film for solar photovoltaic modules

- 280 Photovoltaic module price

- Photovoltaic boost station energy storage module

- Bandar Seri Begawan double glass photovoltaic module manufacturer

- Venezuela photovoltaic module prices

- Podgorica BIPV photovoltaic glass module

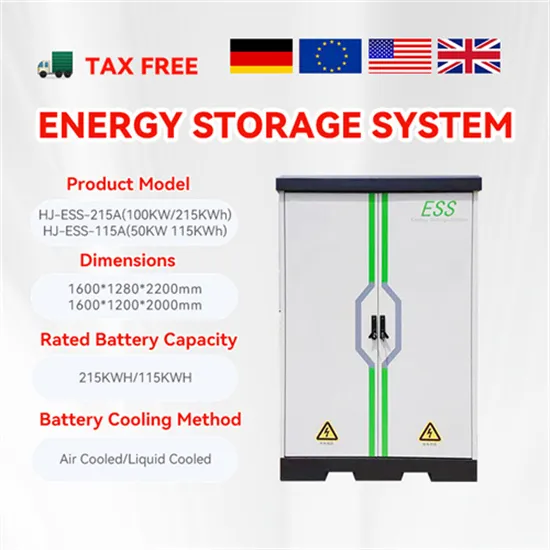

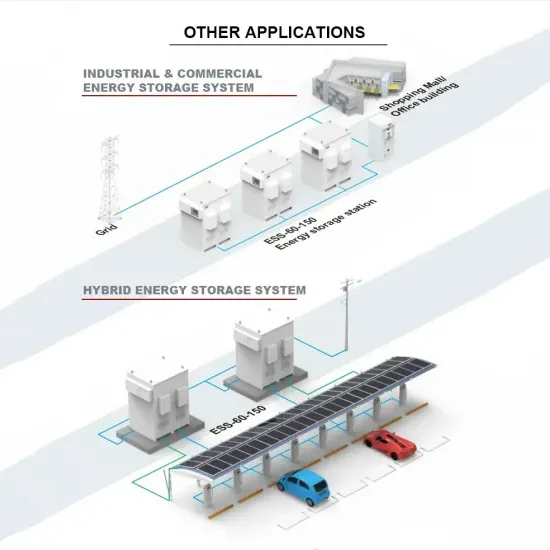

Industrial & Commercial Energy Storage Market Growth

The global industrial and commercial energy storage market is experiencing explosive growth, with demand increasing by over 250% in the past two years. Containerized energy storage solutions now account for approximately 45% of all new commercial and industrial storage deployments worldwide. North America leads with 42% market share, driven by corporate sustainability initiatives and tax incentives that reduce total project costs by 18-28%. Europe follows closely with 35% market share, where standardized industrial storage designs have cut installation timelines by 65% compared to traditional built-in-place systems. Asia-Pacific represents the fastest-growing region at 50% CAGR, with manufacturing scale reducing system prices by 20% annually. Emerging markets in Africa and Latin America are adopting industrial storage solutions for peak shaving and backup power, with typical payback periods of 2-4 years. Major commercial projects now deploy clusters of 15+ systems creating storage networks with 80+MWh capacity at costs below $270/kWh for large-scale industrial applications.

Industrial Energy System Innovations & Cost Benefits

Technological advancements are dramatically improving industrial energy storage performance while reducing costs. Next-generation battery management systems maintain optimal operating conditions with 45% less energy consumption, extending battery lifespan to 20+ years. Standardized plug-and-play designs have reduced installation costs from $85/kWh to $40/kWh since 2023. Smart integration features now allow multiple industrial systems to operate as coordinated energy networks, increasing cost savings by 30% through peak shaving and demand charge management. Safety innovations including multi-stage fire suppression and thermal runaway prevention systems have reduced insurance premiums by 35% for industrial storage projects. New modular designs enable capacity expansion through simple system additions at just $200/kWh for incremental capacity. These innovations have improved ROI significantly, with commercial and industrial projects typically achieving payback in 3-5 years depending on local electricity rates and incentive programs. Recent pricing trends show standard industrial systems (1-2MWh) starting at $330,000 and large-scale systems (3-6MWh) from $600,000, with volume discounts available for enterprise orders.